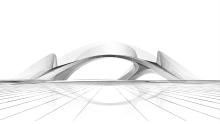

Using its proprietary ECOCycle circular technology, Holcim developed a custom concrete ink for Phoenix with recycled materials inside. Phoenix demonstrates how circular construction and 3D concrete printing can enable low-carbon infrastructure applications.

Circular construction, using computational design and 3D printing, allows for a reduction of up to 50% of the materials used with no compromise in performance. Circular by design, Phoenix stands solely through compression without reinforcement, with blocks that can be easily disassembled and recycled. Holcim and its partners are now exploring how Phoenix could be scaled up to provide more generalised sustainable infrastructure solutions.

Edelio Bermejo, Head of Global R&D, Holcim: “I am thrilled to unveil Phoenix, a monument to sustainability and the result of a fruitful collaboration with our partners to meet a common goal: demonstrating that essential infrastructure can be designed and built in a way that is circular and low-carbon today. This project showcases the impact that innovation can have in Holcim’s mission to decarbonise building for a net-zero future.”

Philippe Block, Co-Director, Block Research Group at ETH Zurich: “Concrete is an artificial stone, and like stone, it does not want to be a straight beam; it wants to be a masonry arch. Following these historical principles allows us to keep materials separated for easy recycling and to dry-assemble the structure for easy deconstruction and reuse. 3D concrete printing allows us to use material only and exactly where needed. The result is a sustainable and truly circular approach to concrete construction.”

Built in partnership with Block Research Group at ETH Zurich, Zaha Hadid Architects Computation and Design Group and incremental3D, Phoenix resulted from the partial recycling of aggregates from the original blocks of Striatus, the first-of-its-kind 3D concrete printed bridge launched by the partners during the 2021 Venice Biennale of Architecture.

Shajay Bhooshan, Head of Computation and Design Group, Zaha Hadid Architects: “Phoenix is a significant milestone in technology readiness. It showcases the maturation of integrated design to construction technologies that were initiated with Striatus. There have been improvements in the robustness of the digital design tools, closer alignment with the numerous structural design and circularity-related improvements, tighter integration with robotic concrete printing parameters and extensive calibration to improve the efficiency of production of almost double the number of blocks in less printing time.”

Johannes Megens, Co-Founder, incremental3D: “Thanks to its design principles, Striatus already represented 3D concrete printing in its purest possible form. Now, after two years and in its second iteration, Phoenix adds a largely reduced carbon footprint and permanence according to building codes, along with many other further improvements. Consequently, we, the incremental3d team, are very excited about Phoenix, and we are looking forward to many other projects that will evolve in a similar spirit.”