Of the various products that have come to market to improve blast performance, flyrock control and productivity, stemming plugs have probably been looked upon with some cynicism. At a time when South African quarries are contending with shrinking business due to a stressed construction sector, ERG Industrial, a young company that in 2019 acquired the distribution rights of the Varistem stemming plug range from United States company, MOCAP, believes stemming plugs are an opportunity to increase efficiency for quarries and mines, thus reducing costs.

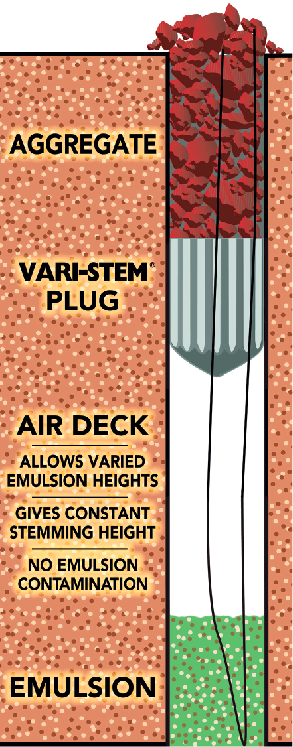

Eugene Preis, MD of ERG Industrial, explains that stemming plugs are placed between the explosive column charge and stemming. Plugs work by creating an additional blocking effect within the drill hole when blast energy is released, directing more energy into the block and less energy upwards out of the drill hole. Upon detonation of the explosives, the plug is forced upward into the stemming material and “locks up”. The explosives gases and energy are prevented from travelling (venting) up through the drill hole.

Typically, the loss of explosive energy through stemming ejection reduces the performance of the blast. The fundamental theory promoting the use of blast-improvement and containment plugs is that they could enhance the effectiveness of stemming material in the blasthole. As a result, this would better contain the explosive energy within the rock mass and yield a more controlled and efficient blast.

Varistem is now available in Africa through ERG Industrial – excluding a few countries like Zimbabwe and Congo, due to US trade restrictions in those countries. Varistem is a patented blast stemming plug designed for quarrying, mining and civil blasting applications. The plugs are said to contain blast energy for longer, resulting in a range of benefits depending on how it is incorporated into the blast design.

Preis says maximum blast containment means greater fragmentation and micro-fractures, with more tonnage processed at less cost. “Following ore body fractures created by the explosive shock waves, the Varistem improves expanding gas containment. The greater the gas containment time within the ore mass fractures, the better the fragmentation. Getting your fragmentation right is substantially cheaper than having to do secondary blasting or mechanical breakage,” he says.

In some cases, the Varistem has achieved up to a 25% increase in fragmentation, which in turn reduces crushing costs and increases crusher throughput. Independent studies also show that the Varistem can increase blast pattern spread by 10% or more, with the same fragmentation for major savings in drilling and explosive costs. “Benefits abound – the Varistem provides blast confinement, resulting in better ore fragmentation, greater crusher throughput, reduced crushing costs and better blast control (less fly rock, vibration and noise),” says Preis.

There are several ways in which the Varistem can be used to improve blasting performance. One of them is air-decking. Historical studies show air-deck volumes of 10-15% can be realised without any major reduction in fragmentation. These studies used air bags for stemming support, which save explosives but do not improve fragmentation. Air-decking with Varistem achieves up to a 27% fragmentation improvement, while also saving on explosives.

“The Varistem also enables consistent stemming heights when using gas emulsions. Simply reduce the emulsion volume allowing for maximum expansion. Set the Varistem in an air-deck so that stemming heights are consistent in all drill holes. This will eliminate short stemming heights and blow-outs,” explains Preis.

Air-decking with the Varistem allows shorter stemming heights, while also reducing explosive column height to dramatically minimise over-sized cap rock from a common 10% oversized, down to a 2% oversized. Flyrock and stemming ejection are also controlled.

When it comes to fragmentation, Varistem plugs increase blast-force retention times by two to four times. The blast force contained by the Varistem is conserved and directed into the rock, greatly increasing the level of fragmentation.

“In addition to the other benefits, quarries, contractors and blasters could potentially reduce the volume and expense of crushed stone stemming, allowing them to use less expensive drill cuttings for stemming as well,” says Preis.

There are several secondary cost savings which result from increased fragmentation – easier rock removal, less secondary breakage costs, increased truck capacity, less wear on crushing and grinding equipment – all of which contribute to the cost benefit of using the Varistem, and which will make the Varistem pay for itself many times over.

Varistem also improves blasting performance through increased pattern spread. The blast energy conserved by Varistem permits operations and blasting contractors to do a lot more with a lot less. Multiple studies have demonstrated that Varistem allows blasters to increase their pattern spread by 10-25%, without any reduction in fragmentation. The cost benefit of increased pattern spread is easy to see – 10-25% fewer holes drilled, 10-25% less explosives used – both of which can greatly help reduce the direct expense of drilling and blasting.

Varistem has been used in the United States for the past 16 years, and in Canada and Australia for the past 10 years. It has also been deployed at operations in Thailand, Ghana and multiple European quarries. In one of the flagship studies conducted by Holcim Cement at its St. Genevieve Quarry, data shows that the expanded pattern size of 14 x 19 inch with the implementation of the Varistem plug yielded improved overall fragmentation compared to the existing 14 x 18-inch pattern typically used by the operation.

The added fragmentation performance represented a reduction of 11.6% in the “mean” size of the rock. The increased fragmentation benefit permitted the usual 14 x 18-inch blast design to be increased to the 14 x 19-inch pattern, thus eliminating 6% of the blast holes necessary to produce the same volume of rock with improved fragmentation.

Studies and in-field tests from the very same operation also showed that the Varistem plugs could increase fragmentation significantly. Three test blasts were carried out at the quarry, with the initial test confirming a 27% fragmentation improvement using Varistem.

Elsewhere, Seven Pines Quarry in Ontario, Canada, recorded significant savings and environmental impact reduction from air blast. Using the Varistem, the operation saw double success though reduced noise/vibration levels and a reduction in explosive costs of approximately 12%.

Despite the proven successes of this technology, demonstrated by several successful case studies, ERG Industrial’s approach to local African sales is based on proving the capabilities at individual operations before commercially deploying the Varistem stemming plugs.

According to Preis, this approach is driven by the understanding that figures achieved at other locations may not necessarily be achieved elsewhere due to the varying nature of conditions and rock geology, among other factors. Therefore, each operation’s gains will vary depending on conditions on site.

ERG Industrial has already kicked off operational tests at some local quarries in South Africa. Between September and November 2019, the supplier conducted tests at four of Afrimat’s quarries. The main aim of these trials was to reduce flyrock and increase fragmentation.

“At two of the four quarries, we used the 102mm stemming plug to see if we could reduce flyrock and stemming ejection and increase fragmentation. The Varistem plugs were used on benches 10m in height, with stemming heights of 1.4m. Ideally, we would have wanted to increase the stemming height to at least 1.8m for the 102mm trials, but this was not possible at the time. Notwithstanding, we had zero flyrock, but still had some stemming ejection (albeit reduced). In terms of fragmentation, the results were the same as before,” he says.

ERG Industrial did two more tests with Afrimat, this time on 89mm blastholes. “Here, the stemming height was a bit higher, about 1.6m. This is roughly equivalent to having a 1.8m stemming height with 102mm holes. Previously there were problems with flyrock because blasting is very close to public roads. Using the 89mm stemming plug, the trials at the two operations achieved zero flyrock,” concludes Preis.