As quarrying operations continue to be transformed by digitalisation, EPC-UK’s ability to optimise energy distribution through the blast design process, well in advance of a shot being fired, has furthered the efficiency of our customers’ load and haul results.

From drone surveying practices to the effective application of good blast design principles, our technological progression combined with specialist software developments enables us to accurately measure, record and analyse performance data, optimising the blast for efficient excavation and more targeted fragmentation.

Digitalised load and haul

At EPC-UK, we’re successfully applying state-of-the-art technologies to achieve the most efficient distribution of explosive energy across the quarry face. We can design blasts to achieve optimal fragmentation of the rock by doing this. We can also tailor rock pile geometry for the equipment on individual sites, resulting in good face conditions and well-managed floor levels following excavation. The targeted fragmentation produces rock piles that are easier to dig, require less engine strain and fuel and have better loading rates per bucket. Machine wear and tear is consequently reduced, and loading cycles quickly become more consistent.

Achieving these results centres around optimised energy distribution. In essence: well-designed, efficient blasting creates less oversize, reduces excavation issues, increases face excavation machine efficiency, and limits the need for secondary breaking and its associated costs.

Drone data

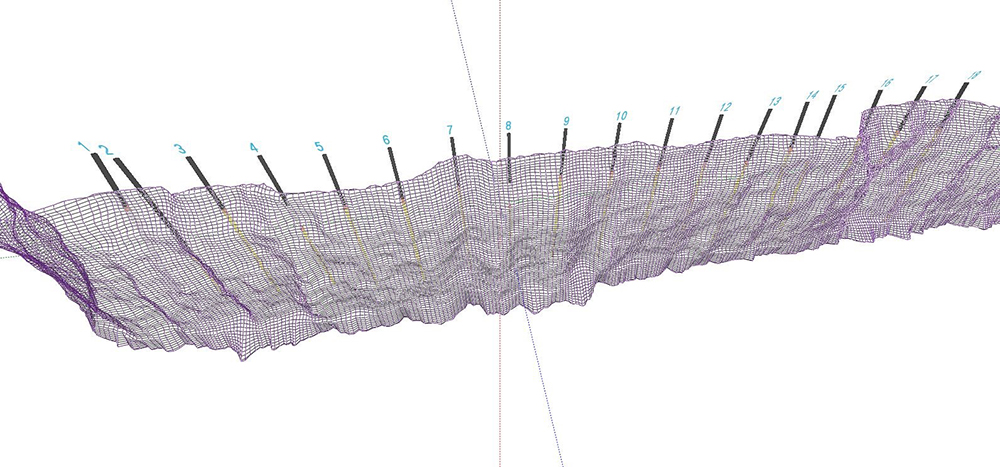

EPC-UK applies a series of digitalised techniques to improve our blasting processes and associated load and haul results. Drone technology comprising advanced photogrammetry is initially used to carry out safe and effective face profiling. This produces highly accurate 3D models of the rock mass to be blasted.

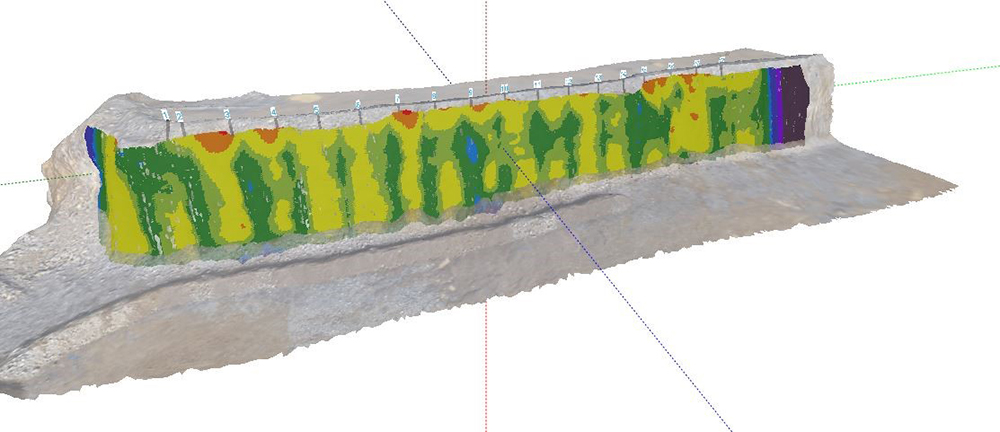

The data recorded by the drones is then analysed using our in-house and highly advanced blast design software, ‘Expertir’. This powerful blast design technology combines multiple streams of data, gathered using drone photogrammetry combined with GPS RTK (Real-Time Kinematics) and hole-probing data to create complex blast designs that are precisely tailored to the surveyed rock face.

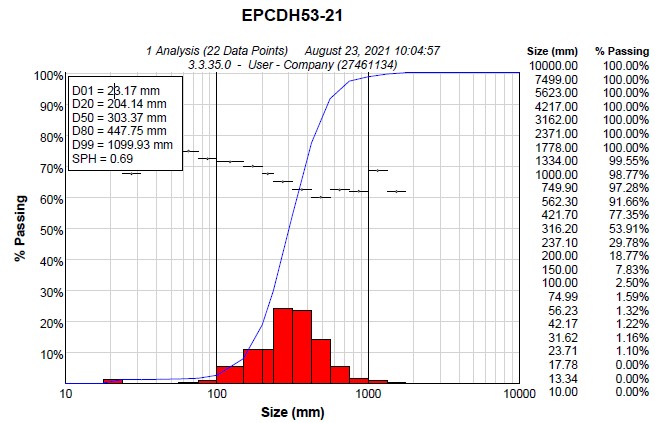

From the collected information, we can produce 3D profiles of the quarry bench before blasting, followed by 3D rock pile models after the event. The models help us to generate precise information throughout the blasting process. They also enable production of the most optimised blast performance from drill-hole positioning through to hole loading and provide data relating to the energy distribution and initiation sequences. This data is then fed through fragmentation and other analysis tools to monitor blast performance about its design and the customer’s requirements.

Precision data

The accuracy of the data from drilling and hole loading is ensured by using our ‘Expertab’ app. This software is a field notebook application linked to Expertir and records detailed information from both drilling rigs and bulk emulsion trucks. The software can both receive and upload data to the main Expertir blast design package, accurately planning and capturing detailed information around each hole that’s drilled and loaded. By harnessing such a complete understanding of hole positioning and energy distribution, we can optimise processes to meet our customers’ production targets.

All key data can also be fed directly back into the Expertir software, demonstrating the technologically advanced capabilities the tools can deliver. The data feed also allows us to accurately record the necessary information to realise continuous improvement within a quarry’s overall operation.

In combination with GPS accuracy and EPC-UK’s existing blast design standards, which incorporate pre- and post-drill surveys and digital hole probing, the blast design packs deliver extremely high levels of accuracy that support excellent blast performance.

Unique capabilities

EPC-UK has built the unique capabilities to offer this advanced level of expertise and integrated service to provide the most accurate picture possible and achieve the best fragmentation and blast performance in its entirety.

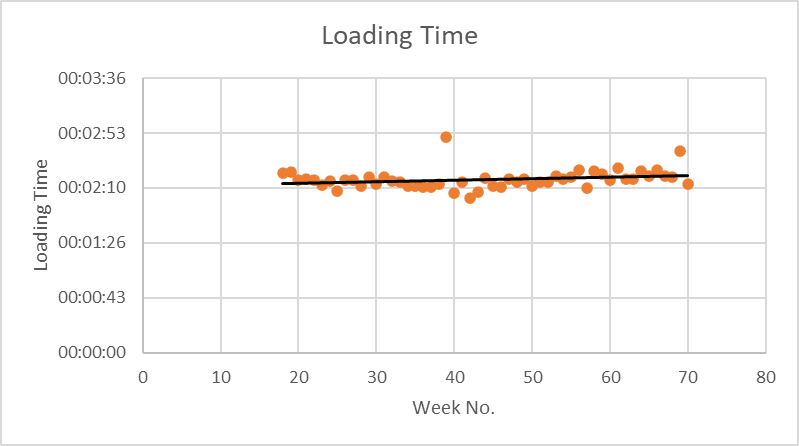

When optimising processes, it is important to understand the impact that changes on the overall process can have. That’s why our operating teams measure a balanced range of key performance indicators (KPIs), both in relation to blasting parameters and the customer excavation and production performance. Providing an example, the following were measured over an extended period in a recent study:

- Fuel used per tonne of rock excavated (face excavator)

- Bucket fill factor

- Number of passes per load

- Overall loading times

- Dumper fill factor

- Blast fragmentation and split of materials as measured at the primary processing plant

In this study, the application of EPC-UK’s blasting technology delivered a significant improvement in fragmentation, allowing the blast’s burden and spacings to be opened out, resulting in an 11% reduction in metres drilled whilst maintaining blast volumes and blast performance. The result was a reduced overall cost to the customer and maintained desired excavation efficiency, material splits, and processing plant performance.

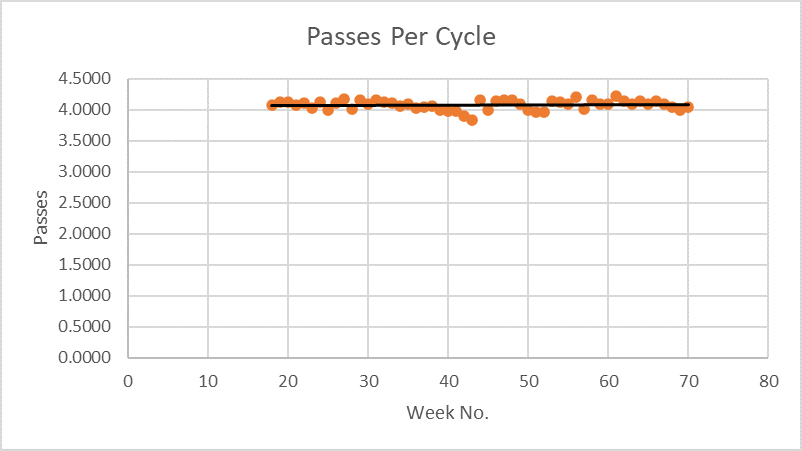

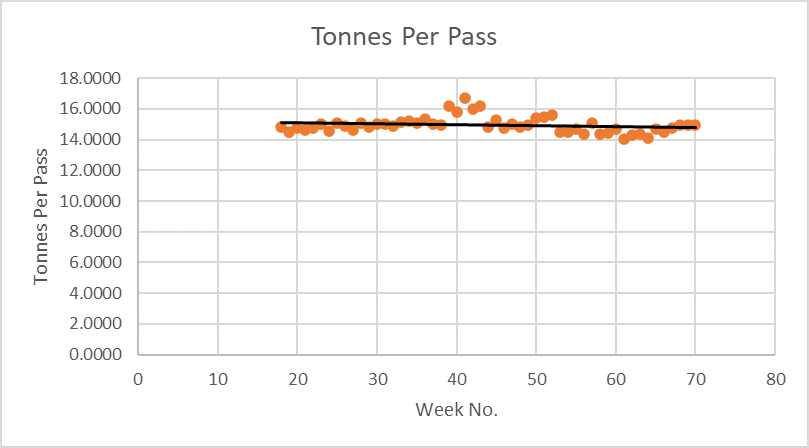

Example graphs

The graphs represent telematic data taken from load and haul equipment, measured in alignment with the blasting KPIs, fragmentation analysis and production plant performance. Blasting cost achievements have been significant, and as an ongoing project, our operations team will further assess the blast design and related factors that can further improve customers’ efficiencies.

Results in partnership

EPC-UK performs activities under its programme of core values, summed up in the word SPIRIT to embody Safety, Passion, Integrity, Respect, Innovation and Teamwork.

Working collaboratively with several UK industry leaders, we delivered a series of site-specific projects and realised effective, cost-saving results by applying our technical knowledge. As leaders within the digitalised quarrying field, we’re plotting the course towards a more efficient, cost-effective and safer industry for all.