At EPC-UK, an industry expert in commercial explosives and drilling and blasting services, drones are fast becoming an integral component of the company’s blast surveying provision. As an element of the EPC Metrics offering, which also comprises fixed remote monitoring, equipment servicing and calibration, and consultancy services, drone technology plays a pivotal role in helping EPC-UK bring next-generation technology to customer quarries.

Delivering the technology of tomorrow, today

Drone technology offers greater accuracy and faster, real-time data collection when compared to a traditional surveying approach, such as lasers. When initially introduced, EPC-UK performed a series of trials to assess the accuracy of drone profile measurement compared to more conventional face profiling methods. It became clear that by acquiring blast imagery from the vantage points, drone technology provided, more precise modelling of blast faces could be achieved. From flying the drone to processing the resulting imagery, the entire process took no longer than 30 minutes and is now proving to be a more efficient method of modelling.

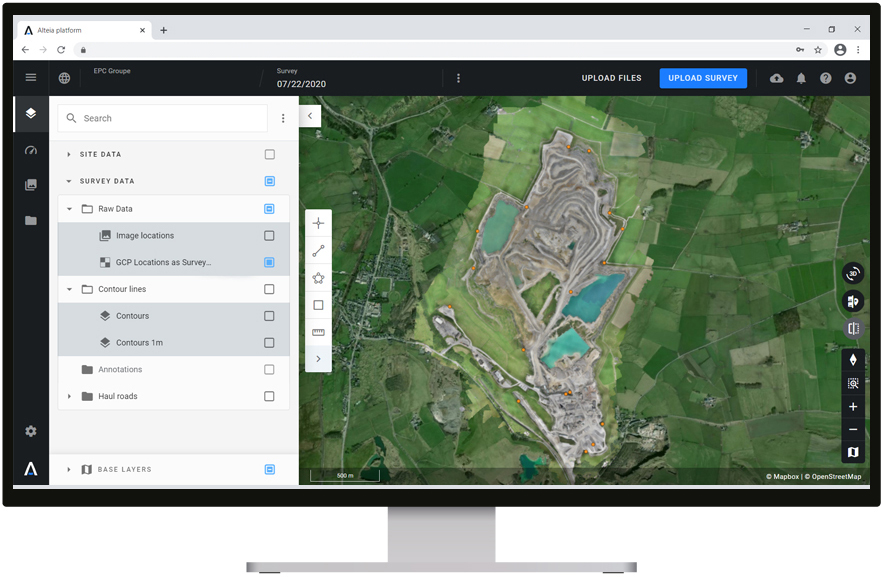

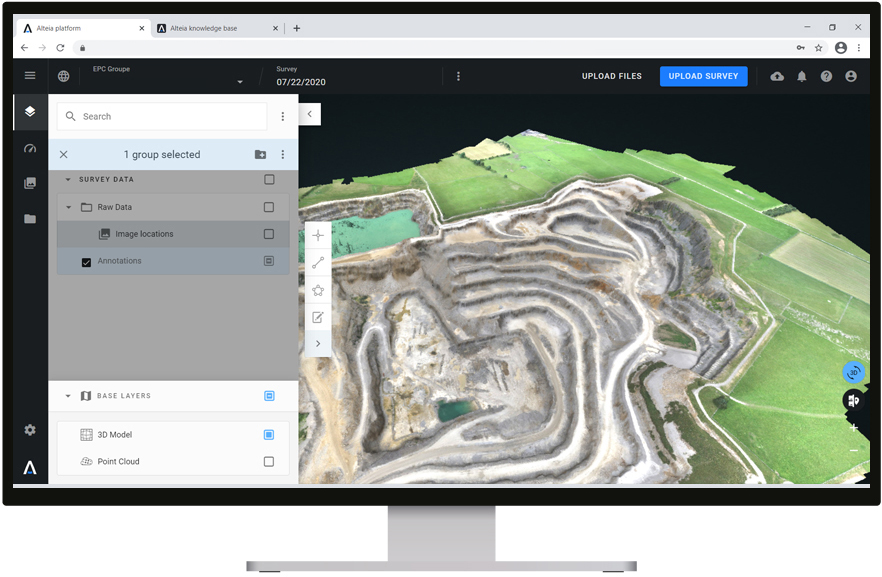

In conjunction with photogrammetric techniques coupled with a photo overlay, EPC-UK engineers can create highly accurate models that illustrate blast faces in incredible detail. Drone-gathered information can be fed directly into Expertir, a highly advanced drilling and blasting software package developed in-house by EPC-UK, turning the data into meticulous 3D models.

This ability to integrate drone technology into other systems is key to its success, as Ryan Ward, commercial manager at EPC-UK, explains: “Here at EPC-UK, we are constantly looking for ways to advance our methods of working, and the implementation of drone technology is exactly that. The use of drones complements our ‘Rock on Ground’ and shotfiring offerings whilst also being the foundation of EPC Metrics and Expertir. It is this integration of technologies, regardless of source, that allows EPC-UK to provide a complete 360° drilling and blasting service to its customers.”

The Drone Team

EPC-UK now has a team of 23 fully trained drone pilots operating across the UK. All pilots have been assessed on three critical elements – a theory exam, a practical flight assessment and risk awareness - by a CAA approved external training and assessment provider. The comprehensive course also included numerous practical simulations to ensure pilots have the skills required to adapt to any situation. Also, each pilot must have at least two hours flight time, obtained in the last three months, to ensure they have the expertise and knowledge to operate EPC-UK’s fleet of drones.

Demonstrating the importance of, and its commitment to, its Drone Team, EPC-UK has just announced the appointment of a new drone manager. This role, which belongs to Sam Skinner, will ensure the safe running of day-to-day drone operations and ensure compliance with all UK legal requirements, developing the Drone Pilot team, and ensuring customer expectations are exceeded.

A graduate of Camborne School of Mines, Sam is an experienced EPC-UK explosives engineer. His extensive technical experience and intimate knowledge of EPC Metrics and the role drone technology plays within that service has led to his selection as drone manager.

“EPC Metrics is a huge growth area for EPC-UK. Incorporating drone mapping services, fixed remote monitoring, equipment servicing and calibration, as well as consulting services, it is fast becoming a core service offering for our customers. The use of drone technology is at the heart of this service, and I am very much looking forward to working with the EPC-UK drone team in my new role as drone manager to develop and enhance our EPC Metrics proposition,” explains Sam.

“Introducing new technology into the extractive industry does come with its challenges, but we need these challenges to ensure we remain innovative and open to adapting to new ideas,” adds Sam. “Here at EPC-UK, we are constantly striving to improve and invent, and this is shown in the drone technology we have chosen to adopt.”

Drone evolution

EPC-UK predominantly uses a fleet of DJI Phantom 4 Advanced or Pro drones. These robust quadcopter drones enable photogrammetry and surveying to be undertaken in the demanding quarry environment. Each drone is equipped with a 20-megapixel camera, which can also support 4K videos, and is perfect for creating an accurate model of an area or videoing a blast.

EPC-UK’s latest investment is the WingtraOne Professional vertical take-off and landing (VTOL) fixed-wing drone. This innovative drone can map large areas with unprecedented image quality and accuracy. Thanks to its VTOL design, it can operate - safely take off, collect data and land - from challenging and limited spaces, making it perfect for rough and busy work sites. It also boosts safety by enabling data collection without the danger of climbing stockpiles or walking amongst moving equipment.

In addition to its VTOL capabilities, the drone hosts a 42 mega-pixel camera and includes the technology to georeference all images in conjunction with a single fixed ground station. The photographs obtained can then be processed using photogrammetry software to generate fully georeferenced 3D models. From this, various measurements such as quarry reserve depletion, haul road analysis, gradient analysis, stockpile surveys, oversize analysis, and bund height analysis can be taken.

Sam continues: “These drones are not only enabling us to provide more precise surveys and a fully integrated blasting service, but they are also helping to improve the safety of both our engineers and customers.”

Safety First

On-site safety is a key focus in any advancement of EPC-UK’s drilling and blasting activities, and it is constantly developing new techniques to allow it to deliver a safer service to its customers. Drones are an important element in this development.

With traditional surveying methods, there are myriad restrictions with regards to where equipment can be placed. This also often involves operators working directly within the quarrying environment where they can encounter heavy machinery and other hazards. However, drones can help eliminate a number of these risks by positioning the operator outside the area of danger.

“Ensuring the safety of our engineers and operators, as well as our customers, is of paramount importance to EPC-UK, and it is the main consideration at the centre of every operation we perform,” explains Sam. “This is why we are always striving to improve safety for everyone involved in the blasting process, and drones are helping us to achieve another level of protection.”

The benefits of a bird’s eye view

In addition to enhanced safety, the benefits of EPC-UK drone technology to customers are immeasurable. It offers customers a unique tool for their blasting ‘toolbox’, from complementing EPC-UK’s blast design software Expertir and enabling blast designs to be more accurately and quickly created to provide valuable, real-time data for all aspects of an operation. Additionally, using a drone to conduct surveys presents an opportunity to view the geology of the rock mass whilst creating an accurate 3D model of a site, a feature that traditional surveying techniques do not offer.

Looking up to the future

“EPC-UK is constantly looking to expand its drone offering, and we have an ongoing strategy to train more pilots and invest in more equipment over the coming years,” concludes Ryan.

“Using technology and integrated systems, such as drones and EPC Metrics, is quite a big shift for the industry and our customers, but we’re confident that it will soon become the norm. The use of drone technology at EPC-UK is fast becoming standard practice. We are already working with a number of customers who use drones exclusively for all of their surveying activities.

“Drones are becoming a facilitator for the digital quarry. They, together with other technologies and innovations, are gradually helping us move towards a completely digital and paperless environment, allowing for greater transparency and immediate data access, as well as providing the most comprehensive, integrated and remote drilling and blasting service possible.”

Further information about EPC-UK, EPC Metrics and drone surveying can be found by visiting https://www.epc-groupe.co.uk/epc-metrics/ or by calling 01773 832 253.