Frustrated with the dust generation and lack of production volume and flexibility of Carriére des Limites’ previous HSI (horizontal shaft impactor) sand tertiary impact crusher, in November 2021 Jean-Marc Fonzé contacted Jean-Philippe Rezette, account manager for crushing and screening at BiA, a longstanding Carriére des Limites’ quarrying plant dealer, to discuss alternatives.

Business at Carriére des Limites’ nearly two-million-tonnes aggregates and sands/year Rochefort limestone quarry in Belgium’s beautiful Ardennes region was good, but the inefficiencies of its impact crusher had the potential to harm the supply of high-quality manufactured sand to their majority ready-mixed concrete-producing clients.

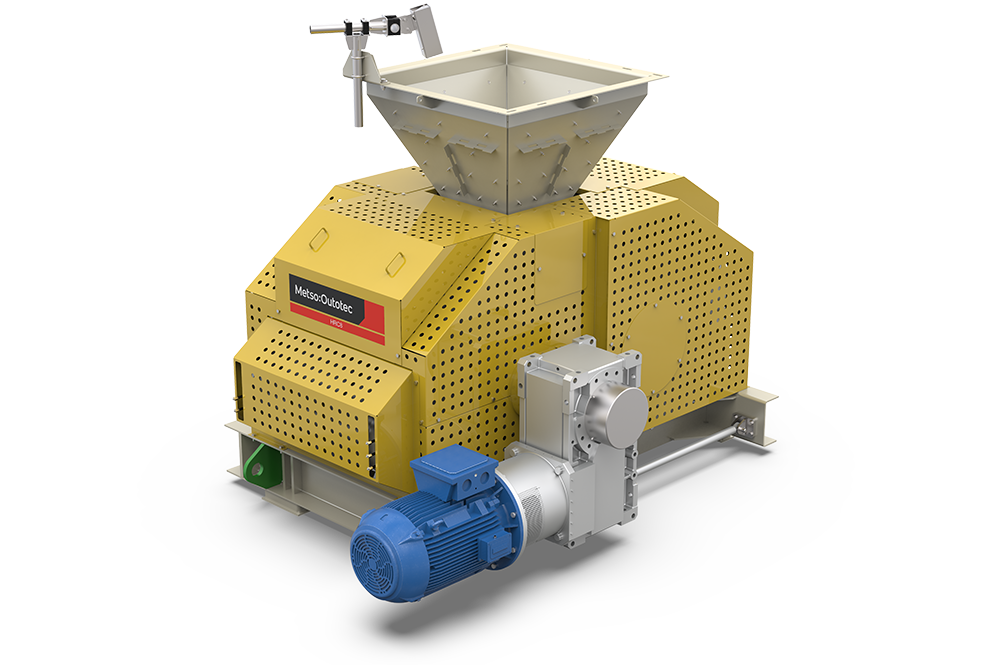

BiA had previously supplied Carriére des Limites with six Nordberg and Metso-branded primary and secondary crushers for the company’s limestone-aggregate-product production, and Rezette knew Metso Outotec had just launched the HRC 8 high-pressure roll crusher. He got in touch with Oldemar Meneses, Metso Outotec’s manager of impactor and sand solutions, based at the company’s Mâcon, eastern France facility, and arranged for him to visit Carriére des Limites to discuss the potential benefits of deploying an HRC 8 plant at the Rochefort quarry.

“With our old impact crusher, we were generating around 60,000 tonnes of stone dust waste a year. That is a lot of waste - rubbish that we cannot sell,” says Fonzé, director of Carriére des Limites’ aggregates division. “We wanted to find a machine that would work more slowly, generating less dust, and could be easily altered to make different types of sand or aggregates product.

“We saw the test results from an HRC 8 processing limestone samples, and we trust BIA and Metso Outotec. We know they are serious people and have a long working relationship with them. If other manufacturers proposed this solution, we would not have chosen it.”

Carriére des Limites has had its HRC 8 since early September and Fonzé and Rochefort quarry manager Hugues Antoine say they are pleased with its initial performance.

“The cubicity of the final product and quality of the fines are good,” confirms Antoine. “I like the fact that we can easily adjust the speed and pressure of the [HRC 8] crusher. We are waiting for results from [HRC 8] tests done on our limestone at [Metso Outotec] Mâcon.”

“Before we had the HRC 8 we had to stop production when our four [different product size] stockpiles were full. Now we have a crusher that can more easily switch between processing different sized products to avoid stoppages. As such, it gives more working hours and optimises production, while generating less waste,” explains Fonzé.

Metso Outotec says that its HRC 8 high-pressure roll crusher can turn large volumes of quarry waste into high-quality saleable product. As demonstrated at Carriére des Limites, the model is designed to ensure energy-efficient operation, flexible operating parameters, high productivity, increased availability, rapid installation time, and safe and simple change-out of long-life wear components.

Unlike Carriére des Limites’ previous impact crusher setup, the HRC 8 eliminates the problem of a high-speed rotor generating very high energy and repair costs and unscheduled downtime. Fonzé and his team are finding that the HRC 8 plant offers flexibility to adjust the pressure applied to the feed material, while simultaneously making the product gradation finer or coarser as required.

All this is obtained simply by touching the screen of the HRC 8’s crusher automation technology, the IC80C.

Commenting on the IC80C, Antoine says: “It’s easy for me to use. It gives me a clear on-screen view of the amount of material going through the machine, the production power and speed, and the pressure on the pistons.”

at Rochefort quarry

As well as serving its manufactured sand production needs, Carriére des Limites is also finding that the HRC 8 can effectively re-crush its 8x20mm product to achieve high-spec 8x16mm and 2x0mm products. The HRC 8 also gives the company the option to re-crush 2x8mm rock and maximise 2x0mm product as demand dictates.

“The biggest thing for me regarding the HRC 8 is how it performs and wears over time, given the constant stone-on-stone pressure. It is not a big machine,” says Fonzé.

Meneses is quick to reassure him. “Given the low silica content in the material that the plant is working with, and the HRC 8’s lower operating speed, I don’t see any problems with excessive wear.” He adds: “Metso Outotec’s main wear-parts warehouse for Europe is in Belgium. We have other HRC 8 plants being commissioned in Germany and Norway, and all the wear parts for backing up these machines will be stored here.”

Established in 1961 by Jean-Marc’s father, Ronald Fonzé, and his business partner, Antoine Kremer, in November 1989 Carriére des Limites was taken over by Belgian construction materials group Socogetra and French giant Lafarge took over the business, strengthening it through significant capital investment.

In mid-2009, Lafarge sold its shares to the Brussels-based Besix Group. In his leadership role, Jean-Marc Fonzé is also responsible for Carriére des Limites’ two other Ardennes-based quarries.

Originally exploited as marble because it takes a beautiful polish, the blue limestone at Carrière des Limites’ Rochefort quarry is, after crushing, screening, and washing, hugely popular among ready-mixed concrete, road, rail, other public construction works, and asphalt plant customers. Its richness in calcium also allows this mineral product to find, after a fine grinding, natural outlets in agriculture and industry.

Carrière des Limites’ markets are mainly in Belgium (49%) and Luxembourg (40%), and to a lesser extent in Holland (9%) and France and Germany (2%). The company has a turnover of nearly €15 million and employs more than 30 full-time employees.

Commenting on the company’s Luxembourg trading, Fonzé says: “It’s a very small but very rich country. Each year, Luxembourg gains many new buildings. Among the contracts we’ve had there have been supplying materials for developing its airport.”

When Aggregates Business visited Carrière des Limites’ Rochefort quarry, it was operational 6am to 10pm, Monday to Friday, using a two-shift pattern.

Environmental best practice is a key facet of Carriére des Limites’ quarrying. At the Rochefort site, the company uses a washing plant and filter press, recycling over 90% (350m³/h) of production water and minimising operating space taken up by ponds. In summer, the quarry is 50% solar-powered, and Fonzé is exploring how best to increase the site’s year-round use of the renewable energy.

“I also looked at introducing a big wind turbine here, but we have military aircraft flying in this area, so it’s not possible,” says Fonzé, who says the large installation of solar panels at Rochefort quarry in May 2021 was well timed given the huge rise in site energy costs due to the impact of the Russia-Ukraine war.

Given its investment in sustainable production and latest plant technology, Aggregates Business would like to return to Carriére des Limites’ Rochefort site to discover the full impact of the HRC 8 and how Fonzé and his experienced team have built on the quarry’s already impressive operating practices.