A medium-sized family-run company that has close links with the quarrying industry is celebrating 125 years in business

According to the memoirs of Carl Haver junior (1884-1976), which the son of the founder of the company (Haver & Boecker), Carl Haver, wrote in the 1960s: “If someone had told my father in the early years of his entrepreneurial activity that his company would at some stage have branches abroad, he would probably have smiled in disbelief.”

With his cousin, Eduard Boecker, Haver established the company of Haver & Boecker on 25 August, 1887 in Hohenlimburg, the German centre for wire drawing and wire weaving at that time.

Eduard Boecker left the company in 1891, and the early years were difficult due to the working conditions in Hohenlimburg and the competition from Thuringia. This changed following the move to Oelde in Westphalia, where the head office of the company has been since 1897.

By 1890, the workforce had doubled from 12 to 24 employees, and apart from wire weaving, the engineering works established in 1925 had developed into the second mainstay of the company.

Among the company’s major products today are screens that are widely used in the quarrying and mining industries. Indeed, in late 2011 Haver & Boecker, owner of W.S. Tyler, whose screening group is based in Ontario, Canada, announced it had reached an agreement with

Representing the Haver & Boecker Group, W.S. Tyler Canada acquired a 40% share of Major Wire Industries on 1 January, 2012 with agreement to acquire the remaining 60% in 2016.

An announcement at the time said: “As part of this alliance, W.S. Tyler Canada will give Major Wire the responsibility to manage the W.S. Tyler Salisbury, North Carolina, USA weaving facility. Other than this one development, all existing operations for both companies, including W.S. Tyler’s St. Catharines, Ontario, and Edmonton, Alberta [Canada] operations, as well as Major Wire’s facilities in Candiac (Montreal area), Quebec and Puyallup (Seattle area), Washington, USA, will continue to operate independently.

“This alliance will prove to be an opportunity for two family-owned manufacturers to effectively employ their combined strengths and expertise to the benefit of the mining, minerals and aggregate markets.”

During the 125-year history of Haver & Boecker, the product range and production processes have been repeatedly coordinated in time with the needs and demands of the particular markets.

The company says that working as partners together with the customers, experience, along with continuous further development of products and production processes as well as the know-how and skill of its employees, provides the main foundation of the company.

In addition, since the establishment of Haver & Boecker, the family, now in the fourth generation, has been actively involved in the management of the company. The legal status is still as a general partnership (oHG).

The importance of education and further training was recognised early on, and records show that training has been taking place since 1905. In 1940, an own trainee workshop was set up and is currently equipped so that the industrial-technical trainees are able to develop and hone their skills there.

In a regional comparison, over 100 young people annually pass their technical or commercial vocational training at Haver & Boecker at an exceptionally high level, and complete it with above average good final exam results.

In 2007, the Haver Academy was set up as a further education platform for employees and customers, and working together with Siemens vocational training and the South Westphalia University of Applied Sciences, it is also possible to train and study for a Bachelor of Arts or Engineering.

Today, Haver & Boecker has developed into a diversified company with a worldwide network of branches and factories employing 2,400 people.

With 50 subsidiaries worldwide, the company as a whole achieved a turnover in 2011 of more than €370 million.

“The wire weaving division with its worldwide network of branches and factories is one of the most important wire weaving divisions,” says Haver & Boecker.

“The production programme covers thousands of different types of wire fabric, over 3,600 of which are kept in stock. Technical woven wire cloth is processed further for screening, filtration and measuring technology.”

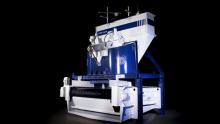

“The machinery division is an internationally acknowledged specialist in the sector of weighing, filling and material handling technology and develops, produces and markets systems and plants for the filling and processing of every type of loose bulk material. In close cooperation with customers and plant operators, technicians and engineers research and develop packing systems using the latest tried and tested analyses, which take into account the needs of a multifarious range of products such as cement, lime and gypsum products, dry mortar, minerals, fertilisers and plastic granulates.”