Brings crushing plants to the smartphone

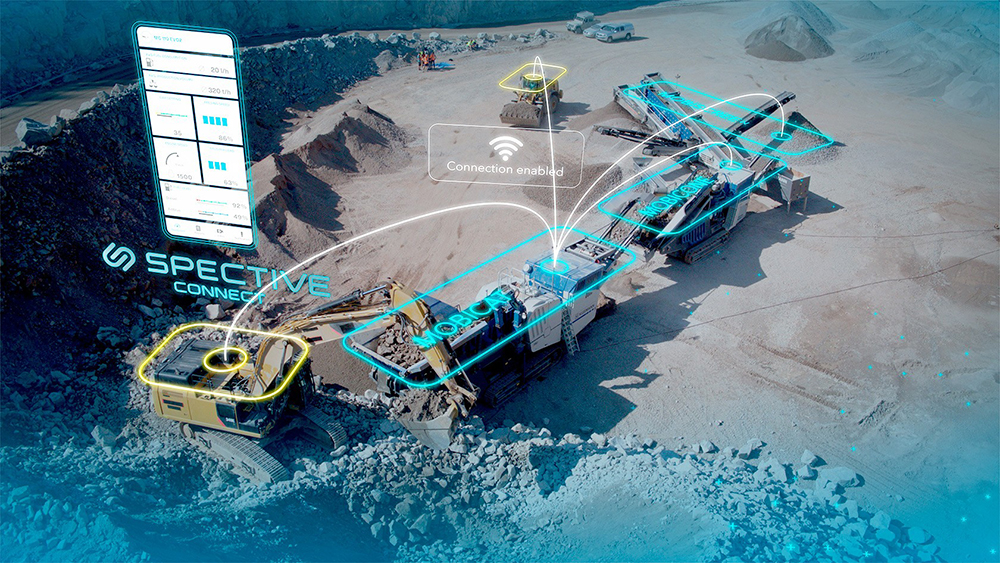

The introduction of the digital operating concept SPECTIVE was a sensation for Kleemann and set new standards for control options for crushing plants. Now the next bombshell has appeared in the form of the extension SPECTIVE CONNECT.

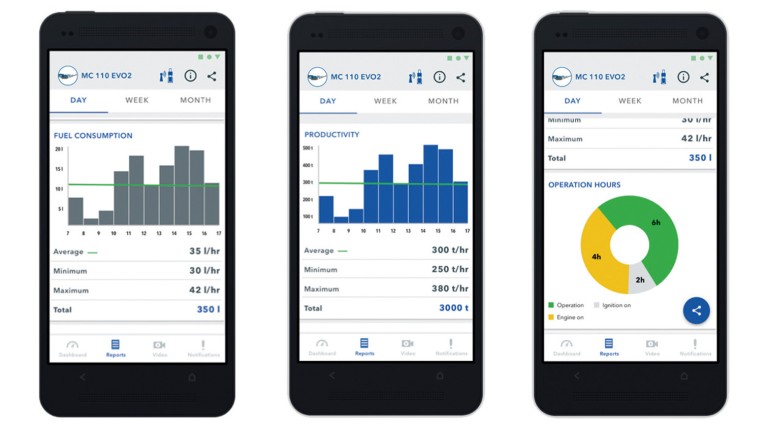

The operator information app shows all relevant process information on the plant such as speed, consumption values, productivity and fill levels, as well as reporting and fault messages. The big advantage: the operator does not have to interrupt work and leave the excavator or wheel loader but still has all important data at a glance.

For the first time, SPECTIVE CONNECT is available for the new jaw crushing plant MOBICAT MC 110 EVO2 and the new cone crushing plant MOBICONE MCO 90 EVO2. SPECTIVE CONNECT is available for iOS and android smartphones and can depict several plants simultaneously if, for example, they have been interlinked for operation.

Advantages that impress

• All relevant data at a glance

• Overview of all plants in the train

• The operator can remain in the excavator/wheel loader

• No interruption to the work process

• Increase in work safety

• Documentation and plant usage can be communicated by reports

You would like to find out more about the intuitive operating concept SPECTIVE?

You can find all information here.

SPECTIVE CONNECT: plant control with real added value

Usually without having to leave the cabin or interrupt the ongoing process

Easy access to relevant information

With SPECTIVE CONNECT, users receive a display of the user interface of the intuitive and clearly arranged operating concept SPECTIVE via smartphone everywhere they are working – for example, in the excavator or wheel loader.

Less interruptions, more safety

The operator does not have to leave the safe and protected cabin of the excavator or wheel loader to receive information on current operating statuses or messages that have appeared or also malfunctions. This permits increased plant utilisation – and thus application efficiency.

Know exactly how much material is to be loaded

The more the operators know, the easier they are able to increase plant utilisation. SPECTIVE CONNECT puts this principle into practice by displaying parameters such as crusher feed, gap opening (CSS) and – with integrated belt scale – the output, thus making continuous optimisation of the process possible.

Simple optimisation of processes

Learn today, apply tomorrow: the documentation of plant utilisation – a report that the app can generate automatically and at lightning speed – guarantees transparency and makes process optimisation possible. Unclear reports on paper are a thing of the past.

One day with SPECTIVE CONNECT

The plant is started via the SPECTIVE touch panel directly at the plant. The operator makes the necessary settings. Once it has been set, the plant then runs in automatic mode. When a plant train is used, after initial set-up the operator can always connect directly to the complete plant train, not just each individual plant.

Ready for SPECTIVE CONNECT?

This begins with a regular plant start. During the initial connection, a QR code appears in the SPECTIVE plant display at the push of a button. The operator scans this with the smartphone. The SPECTIVE CONNECT app is now connected to the plant - always automatically if the user is in the vicinity of the plant.

Advantage: All plant data is always within reach on the smartphone.

Work can start

The operator in the cabin of the bucket excavator clamps his smartphone in a mount. Via the camera system* he first obtains an overview of the situation in the infeed and of the complete crushing plant. Then he begins loading.

Advantage: Obtaining an overview of the plant without having to leave the excavator cabin.

*expected to be available from 2022

A fault occurs

The operator receives a message that the cooling system of the MC 110 EVO2 is not operating correctly. Without having to search, he goes in a target-oriented manner to the component to be inspected and receives a description of fault elimination directly. He removes dust from the fan. Fault is corrected. Work can continue.

Advantage: Direct fault display without a search.

Request for refuelling vehicle

The excavator operator notices in the dashboard of the app that the diesel fuel level of the MC 110 EVO2 plantis now only 27 %. He orders the refuelling vehicle by telephone – without interrupting the process and without exposing himself to danger by walking on the slippery material stockpile in rain.

Advantage: Thanks to messages, work process interruptions are less frequent.

Constant utilisation of the plant train is possible

Everything is stable: the operator can also see the crusher feed at a glance and therefore always knows exactly whether feeding should be faster or slower. He also knows the daily output already achieved in comparison to previous days – and can therefore set his sights every day on setting a new personal best.

Advantage: High output achieved easily.

14:45 | End of shift and report dispatch

At the end of work, the operator sends his supervisor verification of the work performed – in PDF format generated from the app. The automatic report contains information such as average fuel consumption, the production output as well as plant or plant train downtimes and operating times. The operator himself can influence whether and which information is to be added to the report, for example, a necessary tool change. These daily, weekly or monthly reports offer an additional option for analysing and optimising the crushing process.

Advantage: Automated, digital reports instead of time-consuming reports on paper.

Content produced in association with Wirtgen Group