A new specialist training facility at

The centre has been developed by a joint venture between Tarmac, a leading UK sustainable building materials and construction solutions business, and Max Bögl, the largest privately-owned infrastructure engineering company in Germany.

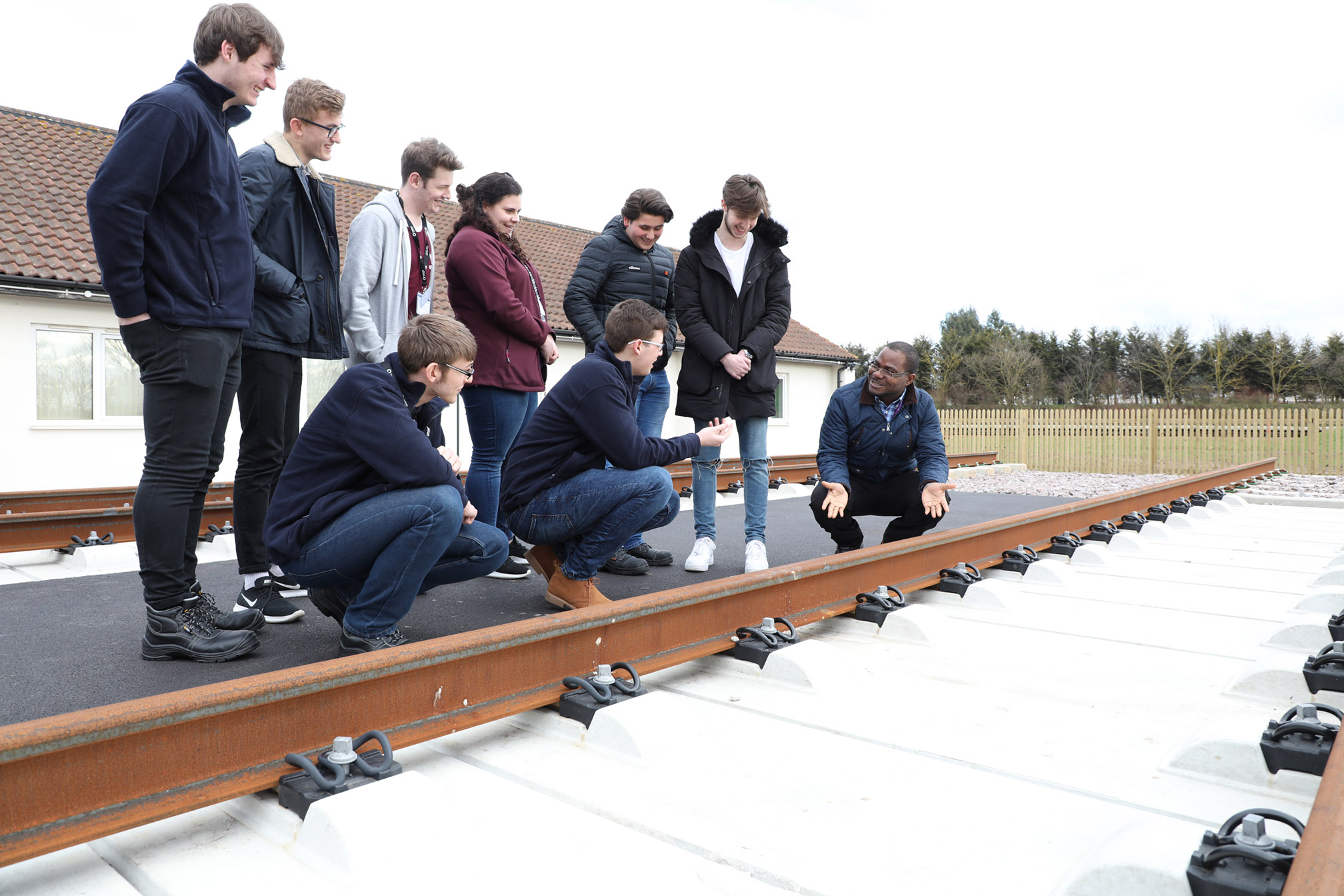

It features 52 metres of the only installed FFB slab track in the UK, an alternative to the traditional rail ballast system designed specifically for high-speed rail applications. NCHSR students will benefit from three training days at the training facility as part of their curriculum, gaining valuable trackside experience.

As well as getting to grips with the innovative FFB slab track system, the trainee civil engineers will learn about ground stabilisation, standard rail and ballast tracks and geotechnical operations. They will also have first-hand access to a site tour of Alrewas Quarry, giving them an end-to-end view of track creation, from minerals extraction to installation, operation and long-term maintenance.

Andy Rowley, commercial director of Tarmac, said: “Building manufacturing capabilities to deliver new safe and efficient high-speed rail networks is critically important for the UK’s infrastructure plans and productivity across all regions. We have built a strong JV team with bags of experience in all elements of the provision of FFB slab track to the UK Rail Sector and our system is undoubtedly the best in class, therefore a location to showcase our know how and the associated benefits of our system is a real positive attribute we are now able to offer to our customers.

“It’s crucial that this is also used as an opportunity to grow domestic skills and technical training, which is why we’re proud to be collaborating with the NCHSR to develop and train the next generation of engineers who will be responsible for these systems. At the new training facility, students will benefit from the extensive industry-leading knowledge of our joint team and the opportunity to get hands-on experience of working with the cutting-edge FFB slab track.”

The JV team worked together to install the track at Alrewas using the same methods employed in high-speed rail construction, including the installation of a hydraulically bound layer and frost protection to ensure longevity. Max Bögl supplied and transported the FFB Slab Track from Germany, with Tarmac supplying peripheral decorative rail ballast, ready-mix concrete, and grout.

The facility also features 120 metres of high speed specification rail track donated by British Steel. A donation was made by Trimble for their slab positioning equipment to ensure accurate alignment of the slabs.

Garvin Okoror, curriculum lead for civil engineering at NCHSR, said: “Our students have benefitted from the subject matter experts at Tarmac, and the sessions were organised to deliver bespoke training modules tailored to suit our High-Speed Rail and Infrastructure courses. Tarmac have been magnanimous in providing the industrial support required in teaching aggregate, concrete, sustainability, logistics, pavement and slab track design.”

The NCHSR students visited the training centre at Alrewas in March and are returning twice in May, with a further session held at the college’s campus in Birmingham. NCHSR students studying on the Sheffield Allam University validated High Speed Rail and Infrastructure course have also recently benefited from training sessions at the new facility.