Due to open in September 2017, the NCHSR, located at Doncaster’s Lakeside Campus, will comprise circa 76,000ft ² of teaching and workshop space. Along with another site at Birmingham’s Science Park, the college will train thousands of apprentice engineers to meet the HS2 and future rail needs by providing a real, hands-on experience for those involved in the high speed rail projects.

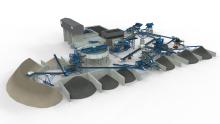

Aligned to its hands-on learning ethos, the college will boast 150m of rail track which will enable students to learn how to place concrete slab track, all of which is being fitted by leading rail group, Rhomberg Sersa.

Core to securing the contract was Aggregate Industries’ unrivalled capability in being able to develop a unique, high grade asphalt solution which exceeds the acute and exacting requirements of High Speed Rail applications. Aggregate Industries, recently secured the contract to install and supply and lay 100 tonnes of aggregate base material and 150 tonnes of asphalt required for the track bed foundation.

Aggregate Industries Contracting division carried the works out within the allocated programme using Non Tipping Trucks due to the track being beneath cover and thus enabling the next stage of works to commence on schedule. The business will also provide the rail ballast aggregate for the students to learn conventional track laying techniques at both the Doncaster and Birmingham sites.

Chris Kearns, of Rhomberg Sersa, said: “The level of accuracy required for a High Speed Railway project of this nature is unparalleled. In terms of the specification of asphalt, it was vital that the thickness, density and strength of the material met the exact specification required for the track parameter. After all, unlike standard highways and roads, any slight deviation on a train track travelling anywhere up to 250 miles per hour, can have huge repercussions.

“As such, Aggregate Industries, having vast experience of delivering innovative solutions and laying high quality asphalt surfacing in rail, was the obvious choice. The team really did go above and beyond the call of duty in meeting our brief and we were suitably impressed”

Chris Withers, business development manager for major projects at Aggregate Industries, said: “We are pleased that our unique capability has been recognised in securing this work. Specification in High Speed Rail applications is a challenge, however, as a business with extensive experience of providing and installing asphalt on road projects, we were able to develop further to include track-supporting layers on high speed rail projects.”