Hanson UK supplied the raw materials for the concrete to main civils contractor BYLOR, which operates the on-site concrete production plant at the new nuclear power station under construction in Somerset, south-west England.

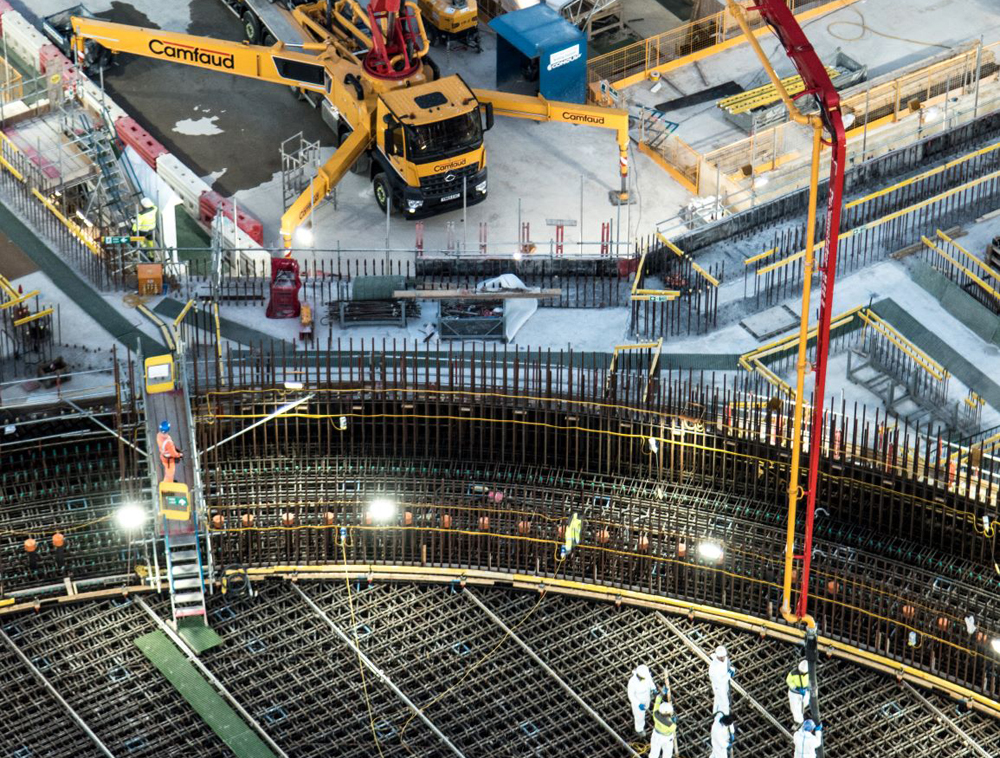

A four-day, 8,991m3 continuous reinforced structural concrete pour, last week, marked the completion of the ‘Common Raft’ for HPC’s second reactor – the reinforced concrete platform on which the reactor, and other parts of the ‘Nuclear Island’ sit.

Described by EDF Energy as J-0, completion of the base meets a date set more than four years ago. It marks the transition from below-ground activity to the construction of permanent reactor buildings above ground.

Completion of the second reactor base also benefited from experience gained on the first identical unit – which has led to significant increases in productivity through steps such as increased use of prefabrication. This will benefit the proposed follow-on project at Sizewell C in Suffolk.

Construction during the current Coronavirus crisis was able to continue after a wide range of measures were introduced to ensure the safety of construction workers and the wider community. This included reducing numbers on-site to enable social distancing and concentrating on the most critical areas of construction. Many health measures remain in force to prevent the spread of infection.

Stewart Cameron, head of nuclear operations at Hanson UK, said: “This exacting project requires every batch of concrete to be exactly the same and comply with the stringent quality standards laid down by the Office for Nuclear Regulation.

“Despite the challenges of working throughout the COVID-19 crisis, our team of 45 employees directly involved in the HPC project adapted well to the major changes required and continued to ensure that concrete of the required quality was produced consistently right first time, every time.”

Hinkley Point C managing director Stuart Crooks said: “I want to thank our partners for their extraordinary efforts to make safe working possible during the pandemic. They have adapted to major changes in everyday behaviours and working practices which would have been unimaginable a few months ago. The commitment of our specialist suppliers has been instrumental in helping us safely achieve this major milestone.”

Hanson is also supplying construction materials to other aspects of the HPC project. To date, this includes 51,000m3 of concrete; 3.5 million tonnes of aggregates; 300,000 tonnes of marine sand; 90,000 tonnes of cement; 145,000 tonnes of Regen GGBS and 140,000 tonnes of asphalt.