Together, the two companies' solutions emit up to 30% less CO₂ during cement production. They also capture and store CO₂, leading to a 70% carbon reduced concrete. With Solidia, LafargeHolcim will continue to develop new innovative solutions focused on non-reinforced concrete structures and paving while also aiming to make it increasingly applicable for structural applications.

Marcel Cobuz, region head Europe: "Leading the way in low-carbon construction, we plan to facilitate a wider and faster roll-out of the innovative Solidia solution across our operations around the world. By scaling up Solidia's solutions, we can fast forward our vision of carbon-neutral cities."

Tom Schuler, president and CEO of Solidia Technologies, added: "By providing market access, technical expertise and market intelligence, LafargeHolcim helped us develop a better cement and concrete. Thanks to our collaboration, we are in the market and expanding. Moving forward, we will advance carbon capture, utilisation and storage technologies and develop solutions for the full, global concrete market."

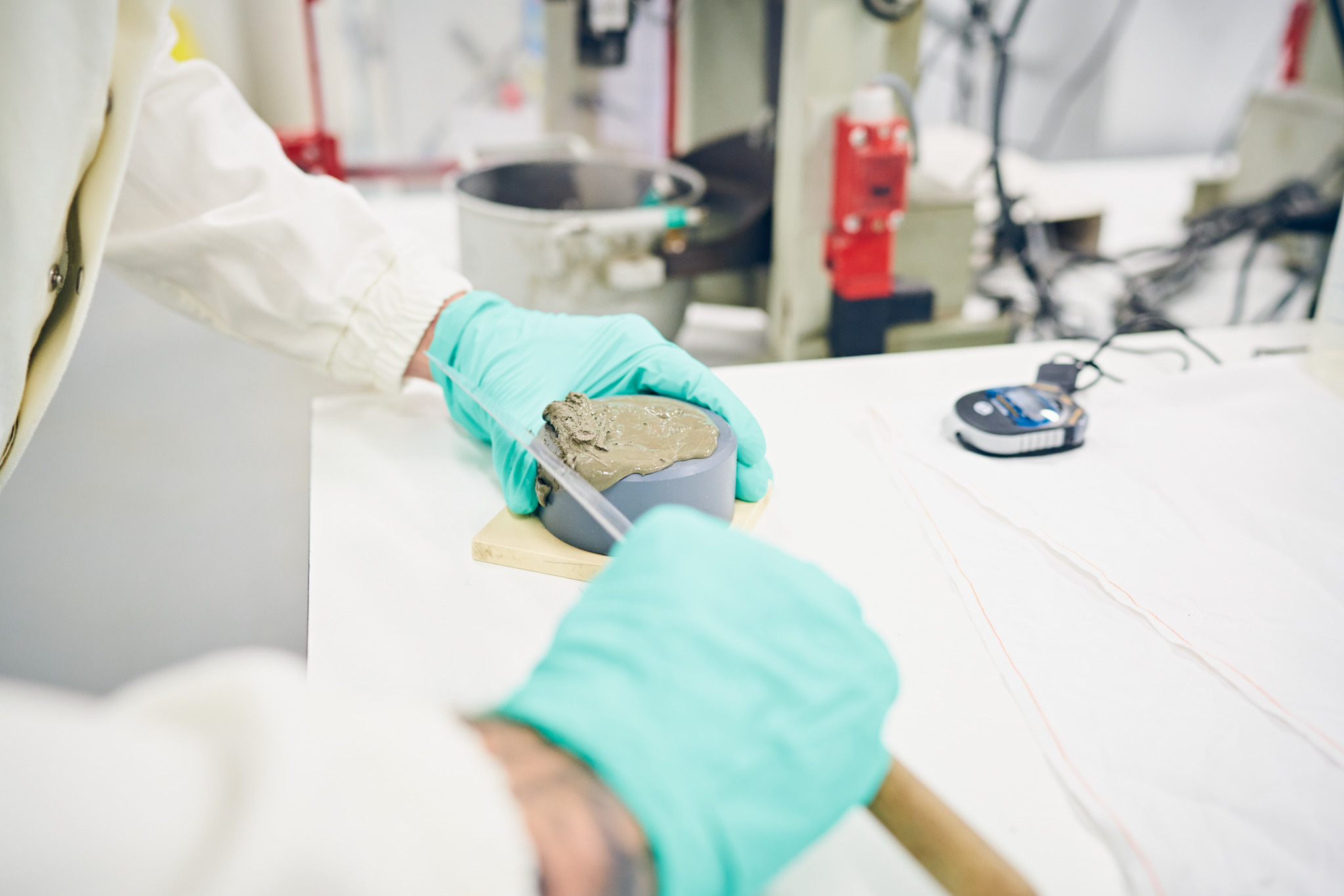

Key US customers have already placed orders for Solidia Cement to produce concrete paving blocks using Solidia technology. In addition to delivering a low CO₂ product from a low CO₂ cement and permanent CO₂ sequestration in concrete materials, Solidia cement can also increase precast production output from full product strength in under 24 hours (compared to 28 days for traditional concrete) and less equipment downtime for cleaning. Solidia Concrete products are more durable and have a wider colour palette and no efflorescence.

Industrial pilots are currently also ongoing in Canada, Germany, France and the UK, with further pilots being prepared.

Initially, the required CO₂ will be supplied by third parties while Solidia supplies the required curing chambers in which the CO₂ is injected into the concrete. Over the long term, LafargeHolcim aims to utilise CO₂ captured from cement kilns in North America and Europe.

Thanks to its efforts in the field of decarbonisation – from operations to products and solutions – LafargeHolcim contributes to a built environment that will be carbon neutral, fully recyclable and with a positive environmental impact. Putting its innovation to work, more than 50% of the Group's research resources are focused on low-carbon products and solutions, with 40% of patents currently in this area. Working across the entire construction value chain, approximately one-third of 2019 sales were in sustainable solutions and products.