"When starting the C120 project, we listened closely to our customers and collected field data from a number of sites. Based on that, we decided to design the crusher cavity and kinematics first. As a result, Metso can now offer aggregates producers, large-scale contractors and mining companies a new crusher that meets all the standards set for any demanding application," says Ilkka Somero, Metso's product manager for jaw crushers.

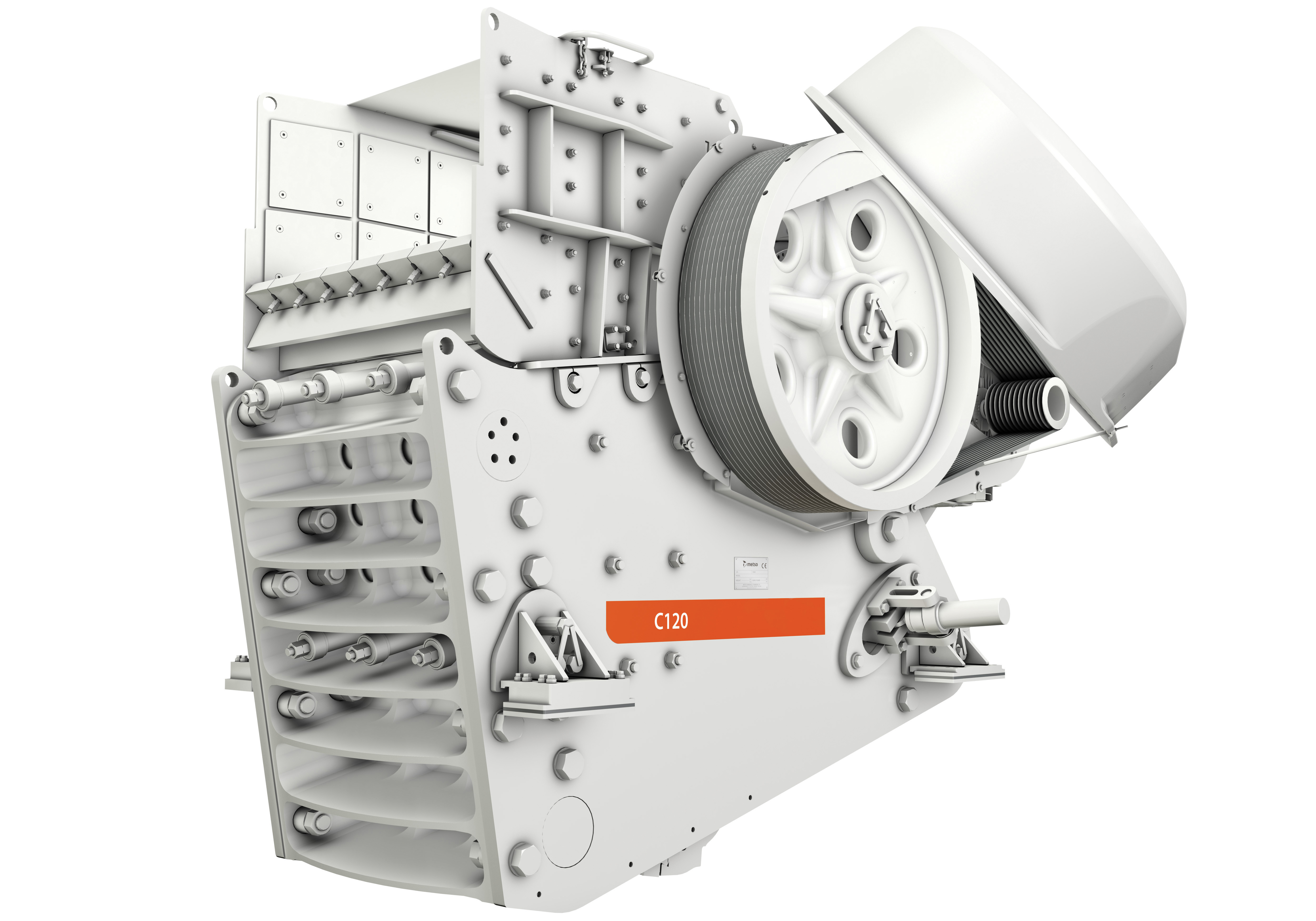

The crusher features a long and aggressively directed stroke, and a fixed jaw die longer than previously seen in this crusher size class, says Metso. The C120 has a large feed opening of 1,200 x 870mm and an aggressive cavity cross section, securing a high performance and reduction ratio.

"Being well-balanced, the C120 is quick, easy and cost-efficient to install through rubber mounting pads underneath the crusher mounting brackets. No separate horizontal supports are needed. The crusher can be mounted in multiple ways to ensure an easy fit onto an existing or a new steel structure," says Metso, which unveiled the unit at

For the setting adjustment, it is possible to select either a mechanical or hydraulic setting adjustment system. For jaw dies, several cavity options are available. Depending on the customer's preference, it is possible to use either single or two-piece jaw dies.

The Metso C120's nominal power is 160kW; operating speed 230rpm; closed side setting between 70-200mm. The operational weight is 26,000kg, excluding options.