Global earthmoving attachments specialist,

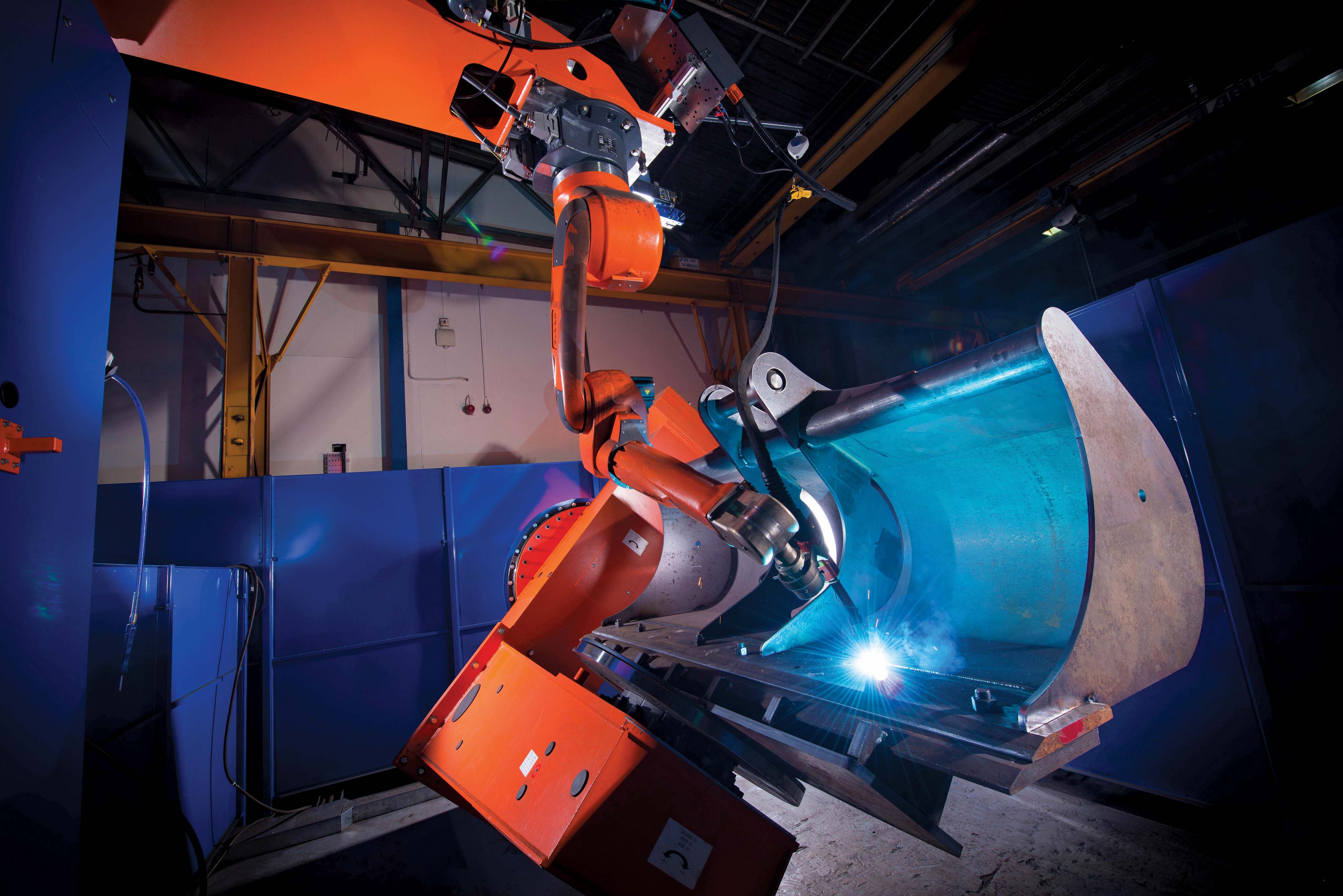

The investment has focused largely on three key areas: productivity, service level and lead time reduction, which centralised on competitive bucket manufacture.

Following the initial investment, some areas have already seen a significant increase in productivity, and this is set to increase further with the installation of three additional new robots to optimise capacity during busy trading periods. Other improvements include two plasma cutting machines and a dynamic parts storage system.

Planned stockbuilding will be carried out in quieter periods.

“This initial investment, which is part of a major long-term plan designed to guarantee that we can continue to provide high quality, competitively priced attachments,” says Mike Askew, managing director at Miller.

“It demonstrates our commitment to manufacturing in the UK. Continual investment in our product range and manufacturing processes is vital to ensure we are able to meet the needs of our customers while remaining competitive in a global marketplace.

“We are looking firmly ahead now and by creating a lean and efficient manufacturing process, we are confident that we are ready to tackle any future challenges head on.”