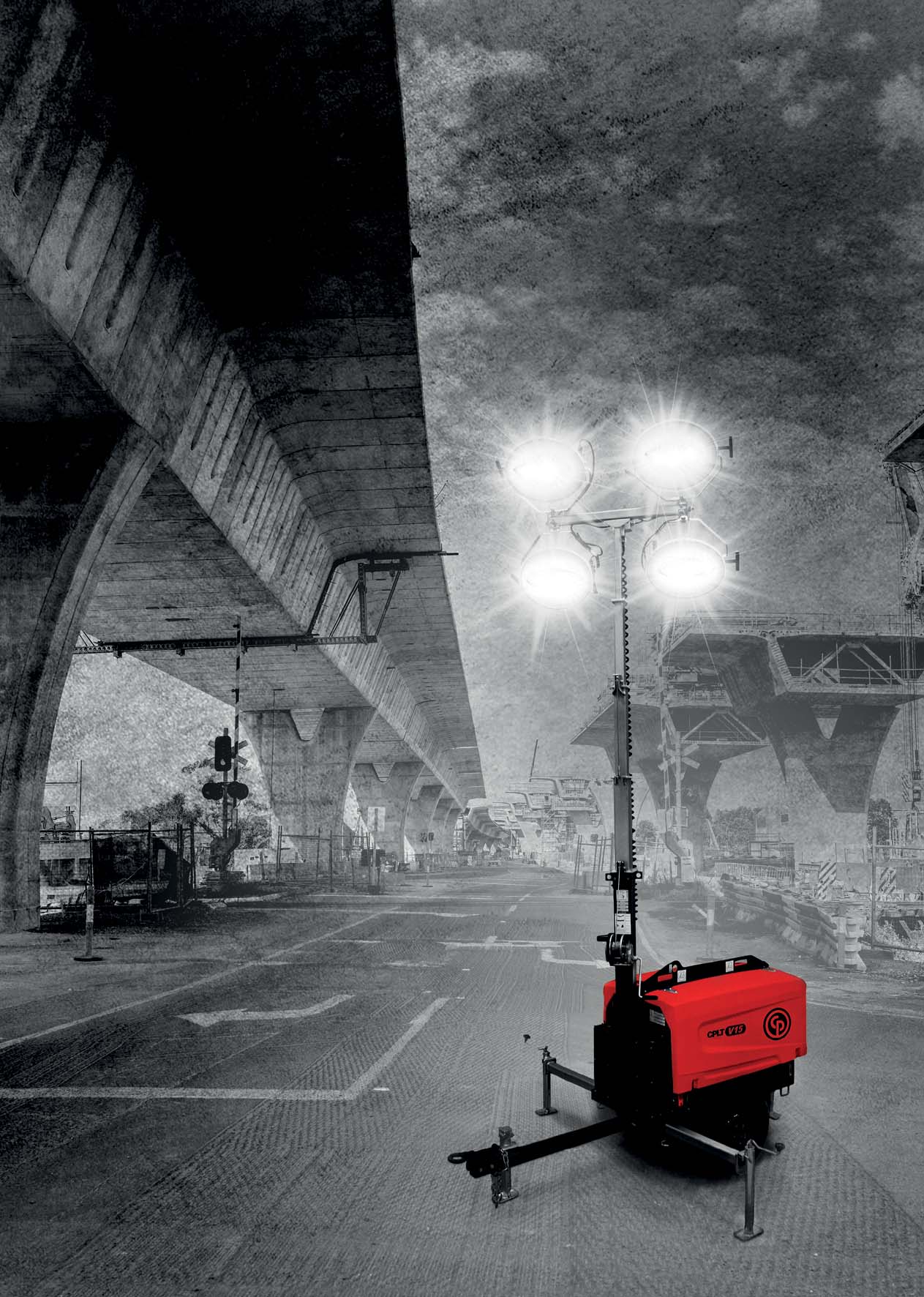

Both new V15s allow workers to operate safely in any ambient light conditions. The CPLT V15 comes with metal halide technology, while the CPLT V15 LED features LED lighting technology and is said to be able to light an area around 25% larger, while proving additional fuel efficiency benefits.

A Kubota EPA Tier 4 engine powers both options, and to ensure operational efficiency as well as fuel efficiency the units are equipped with a 28-gallon fuel tank. In practical terms this allows the light towers to operate for many days without the need to refuel, helping to maximise productivity and illumination time.

Because of the harsh conditions in which the light towers are likely to operate, the new PE canopy protects vital internal components to ensure peak performance and offer optimised lifespan and resale value. Not only is the canopy durable, but it also features wide wing doors to allow easy maintenance access to the machine, including service components and drains. The V15 range also has an environmentally friendly frame that prevents any excess fluid escaping.

Even in the most demanding conditions, the V15s ensure complete safety at site with four heavy-duty stabilisers and a level indicator. Designed for easy transportability to or around the work site with a compact and lightweight design, the light tower can be transported with the mast in the vertical position, allowing safer transportation and installation.

“These light towers tick all the boxes and provide complete peace of mind when it comes to even the most demanding job site,” Says Henry Xu, product manager for Chicago Pneumatic. “The CPLT V15 range offers customers a choice of options to fit their exact needs and deliver the most efficient product for their site, along with offering great value for money – as customers have come to expect from Chicago Pneumatic.”