The company says that the focus is on solutions that are designed to optimise costs, increase production and improve process efficiency.

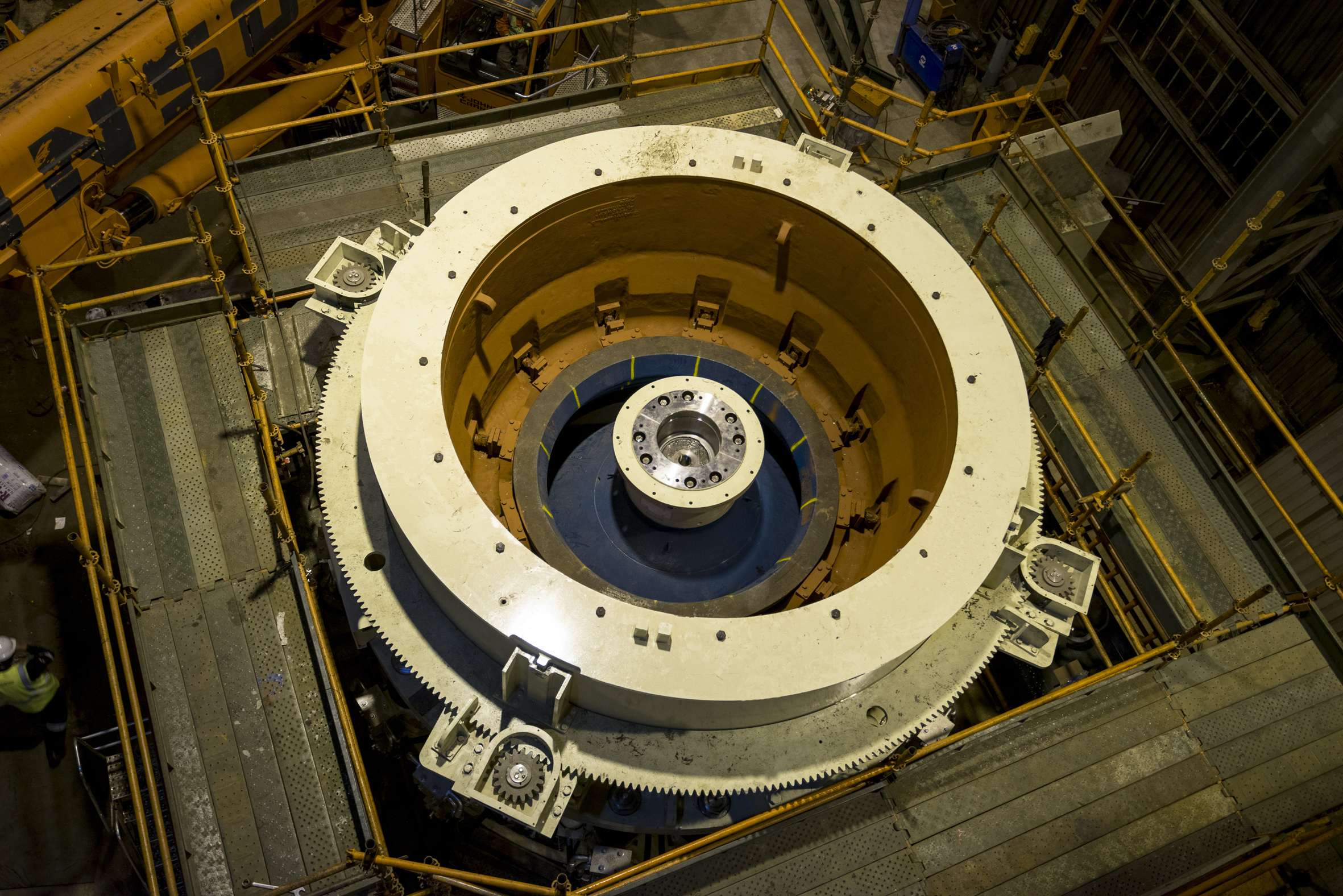

The event, in the capital Lima, runs until Friday ( 16 September), and Booth 208 and 209 B is where Metso will highlight mobile crushing plants, crushers and services for the optimisation of crushers. Among Metso solutions at the exhibition are the Lokotrack LT200ET, a fully mobile 850tonne jaw crushing plant, said to offer high flexibility and low operating costs; the MP 2500 cone crusher, capable of processing large volumes of ore in a single crusher, and the Metso solution for improving the operation of primary gyratory crushers and conical crushers through accurate monitoring and optimisation of profiles and cavities.

“Metso's experience derives from our huge installed base of mining equipment operating worldwide. To truly contribute to our customers’ success, we not only focus on traditional cost reduction schemes, but also on enhancing the value we can generate through our knowledge and on the customer-centric technical assistance our service experts provide for our customers," says Aldo Cermenati, senior vice president, Pacific Rim Market Area, Metso.

"At Expomina, we are excited to present some of the industry-leading innovations designed to help our customers take new leaps in their process efficiency. To make it even more concrete, visitors can see and study the giant MPTM 2500 in three dimensions, presented with an impressive hologram technique.”