Tamrock is a name that is synonymous with rock drilling today but without the work of Matti Kilpinen it might have been a different story. ABE reports

Today the brand name Tamrock is closely associated with rock drills but it hasn't always been the case in terms of name, even if the company's focus on innovation has remained unchanged.

Initially Finland-based company Tampella marketed its rock drilling equipment business under the name of Tampellan konepajateollisuuden paineilmakoneosasto. The name Tamrock was masterminded by Matti Kilpinen when he joined the business unit of Tampella Engineering Works in late 1965.

Kilpinen was a mining engineer who had started his career at Outokumpu, which was then the largest mining company in Finland. However, he had other more acute challenges to sort out in his new position before he could devote his time to the brand.

Tampellan konepajateollisuuden paineilmakoneosasto may seem complicated but many used to be far more complicated. In 1960, the business's parent company changed its name to Tampella despite a 100 year history under the original title of Tampereen Pellavaja Rauta-Teollisuus Osake-Yhtiö, which translates as Tampere Linen and Iron-Industry Ltd.

Drill manufacture in Finalnd started during the Second World War to meet national demand.

Up until then all the drill used were manufactured outside of Finland but the war prevented the import of spare parts. Outokumpu approached Tampella and asked the company to start the manufacture of spare parts. Tampella agreed and spare part manufacturing began as a small unit within the company's Arms Division.

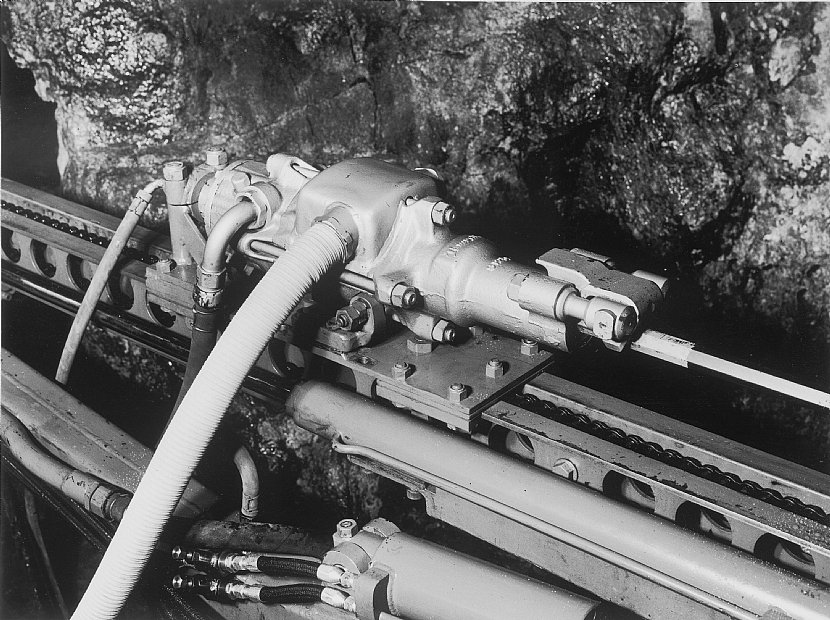

In the late 1940s Tampella decided to start making its own drills with the fi rst on offer in 1952, which were sold to the city of Tampere - the home of Tampella. In 1954 the unit became a department by the name of Tampellan konepajateollisuuden paineilmakoneosasto and so raised its status with the parent company. The same year also marked a major achievement with the fi rst exported drills to Turkey.

However, the development of the division was slow and at times Tampella's company management did not have confi dence in its future. In 1965, when Kilpinen joined, the department was known the compressed air machine department due to that the unit also manufactured compressors, which were favoured by the management.

As a mining engineer, Kilpinen naturally had confi dence in drilling equipment and under his management the sales were good and also exports increased. Drilling equipment was already sold worldwide into tens of countries.

At the time the drills had the name Tampella but Kilpinen wanted something less generic. One day he summoned a group of his management team into his home. They gathered around the kitchen table and came up with several suggestions: Tampella Tamrock; Tamrock; Rock Tampella; and Tampella Minco (Mining & Construction).

At fi rst, the new name was Tampella Tamrock but this combination was used only for 18 months before it was simplifi ed to Tamrock, which stayed as a household name of drilling equipment for a few decades.

In the late 1980s

Despite the change in ownership at the start of the 21st century, Sandvik decided to maintain the name Tamrock as a brand name for its rock drilling products but the equipment continues to be manufactured in Tampere, Finland.

Sandvik has requested ABE to note that it did not participate in the writing of this article