Legislation may have influenced recent technological development but the diesel engine is still ubiquitous when it comes to powering construction equipment. ABE takes a look at its inventor, Rudolph Diesel

While the latest machines are using hybrid technology to improve efficiency, almost all construction equipment owes its mechanical ability to the power of the diesel engine. But until Rudolph Diesel launched his first synonymous engine, the construction equipment and aggregates processing industry relied on the inefficiency of steam power.

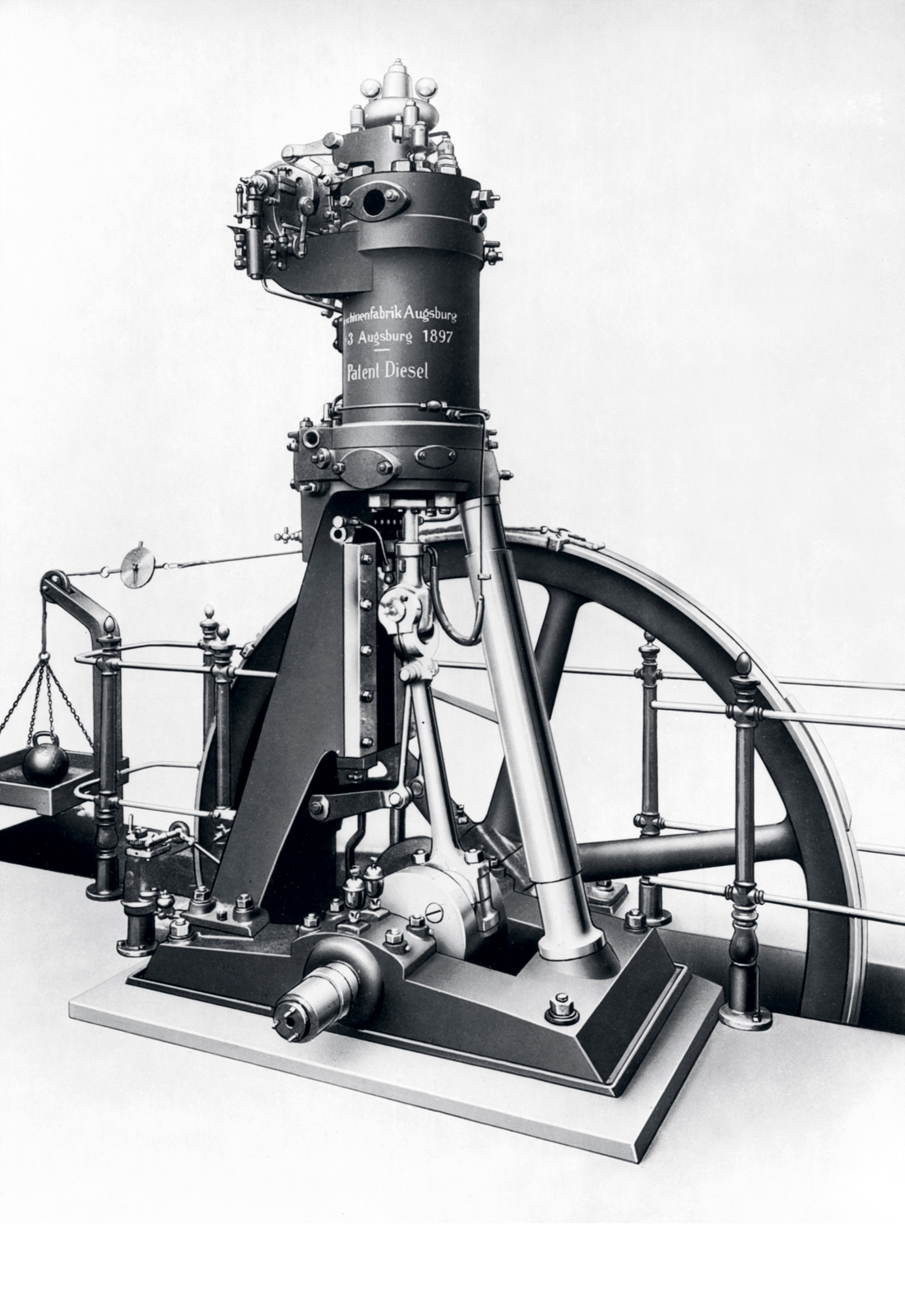

The poor energy efficiency of steam was something that drove French-born German engineer Diesel to seek out a better alternative and in 1897 he obtained a patent as a result of his research. The result was a new engine design with fuel injected at the end of compression where the fuel was ignited by the high temperature caused by the compression - the world's first diesel engine.

Diesel was born in Paris in 1858 to his German-born immigrant parents Theodor and Elise Diesel but his family were forced to flee France in 1870 with the outbreak of the Franco-Prussian War. Diesel's family travelled to London and he was sent to live with relatives in Augsburg in order to study in Germany.

After finishing his basic education, Diesel knew he wanted to be an engineer and enrolled at the Industrial School of Augsburg, which led to him gaining a merit scholarship from the Royal Bavarian Polytechnic in Munich in 1875. He graduated in 1880 and started working with his former professor Carl von Linde in Paris on design and construction of a modern refrigeration and ice plant.

In the early 1890s, Diesel moved his young family to Berlin to take on management of Linde's research and development after gaining numerous patents during his work for the company. However, he was not allowed to use these patents for his own personal use, so he started expand his engineering research outside of refrigeration.

His research led him into the field of fuel efficiency and he started to look at ways of improving the steam engine. An early experiment using ammonia vapor in a steam engine almost proved fatal when the machine exploded under test but he was still determined to try and find a more fuel efficient engine. Diesel knew that even well designed steam engines were only 10 to 15% thermodynamically efficient and he believed higher efficiencies should be possible. He worked on developing a new approach to engine design from around 1893 and worked with Augsburg-based Man director Heinrich von Buz to test and develop his ideas. In 1897, Diesel gained the all important patent for his design and started to market the new engine as an efficient alternative to steam and petrol engines.

Diesel's first engine delivered a theoretical efficiency of 75% - a considerable improvement on that of its steam and petrol counterparts of the time. It was this higher power delivery that helped secure the success of what became know as the diesel engine.

However, Diesel never lived to see how his engine design developed and became an important replacement for steam in many applications - he died in mysterious circumstances while crossing the English Channel for a meeting in London in 1913. He went missing during the crossing and his body was not found until 10 days later. Despite his early demise, his name lives on in both the engines and the fuel used to power them.