Rubber specialist

"Previously these were regional products and the designs and ranges varied accordingly," explained Linatex European general manager Bruce Cook. "But now we are drawing together Linatex's knowledge and capabilities to produce single ranges of valves for all markets." There are 19 sizes in the new PV pinch valve range and these are available with five flange sizes and from 15 to 600mm to suit all industries.

"The focus of the design is lowest cost of ownership, not necessarily the lowest initial cost," said Linatex global valve products line manager Jim Geyer.

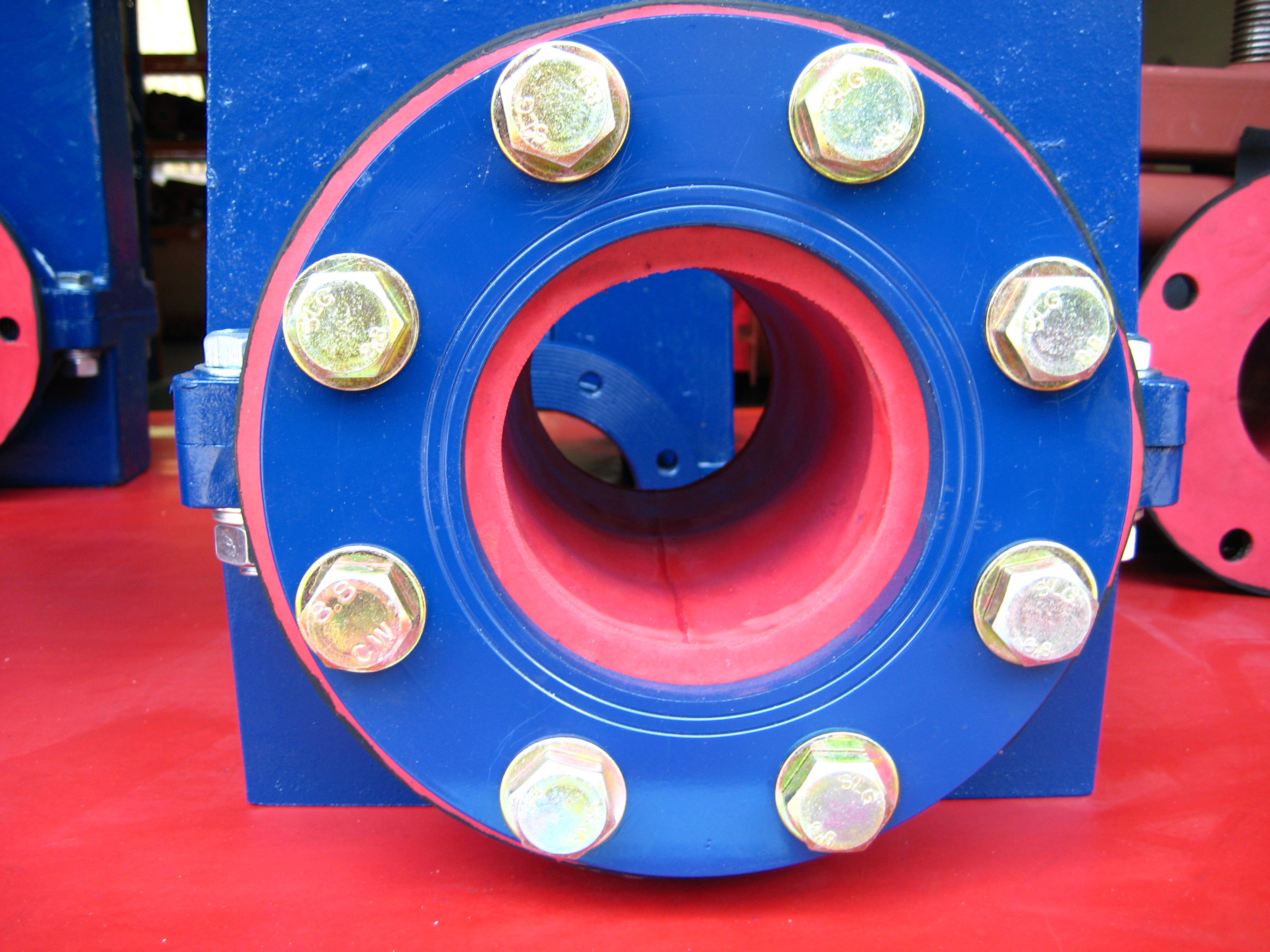

The valves feature Linatex's rubber liners at their core, which Geyer said was essential for resisting wear in abrasive and corrosive environments.

Linatex's rubber is made in Malaysia and uses a patented automated rubber manufacturing technique to retain the longer molecular chains that give it properties similar to natural rubber. According to Linatex, it is these properties that give its rubber a service life four times that of conventional rubber.

"It can stretch to nine times its length without snapping and will return to its original dimensions even after long-term stretching," said Geyer. "These values make it ideal for valves as there is no damage if the valve is shut for an extended period. The rubber also helps absorb energy from abrasive materials." All of the PV range features a rubber valve sleeve that is closed by a double anvil to prevent excessive wear on one wall and down stream of the valve. The range can be specified for manual - with a hand operated wheel - or automatic operation and used at full flow, modulated flow and drip tight closure.

On the closed body version, the pinch bars and sleeve are fully encased in a cast metal housing. The open body models have a fabricated steel body that allows for easy pinch sleeve replacement and allows for fast visual checks of the valve position.