Aggregate production, and associated equipment, is expensive, and training operators is also expensive and time-consuming. However, modern simulators covering a wide variety of quarry equipment can reduce the time taken for training, and also improve health and safety.

Most of the major construction equipment manufacturers have now developed, or are developing, simulators that make training much easier, safer and cost-effective.

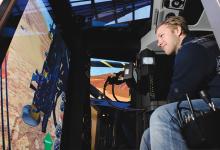

For example, Oryx Simulations has developed a whole new generation of training simulators for

The company says that it believes that operators use all their senses when operating a real machine. That is why it has equipped all of its simulators with state-of-the-art motion bases.

Being able to feel the machine and experience correct feedback from the material being worked greatly improves the training value of a simulator.

Oryx Simulations, based in Sweden, has partnered closely with Volvo CE for several years within the area of construction and contracting equipment, and at Conexpo it launched its new training simulators for Volvo’s excavators and wheeled loaders. They are equipped with a whole new simulator platform, the fifth generation from Oryx Simulations.

“This is an optimised version of our simulators. The whole design is new, making it an all-in-one compact unit. It is easy to move around and no extra equipment is needed. In other words, you don’t have to be in industrial premises. It can be rolled into a normal office space or classroom,” says Clarence Jacobson, Oryx’s products & marketing director.

Oryx says the simulator is easy to use, making it suitable for all types of training companies and vocational schools.

The Simulator Management System (SMS) enables the training instructor to add different driving courses and scenarios, as well as determine the order in which the tasks should be completed by the student. Following which, the instructor can check the log to see how the students managed the tasks and how they have developed.

“The instructor can thereby tailor training both for beginners and experienced operators, as well as follow their increase in productivity. In addition, training takes place in a safe environment: no real accidents can occur in the simulator,” says Jacobson.

“Our training simulators both save money and spare the environment. No diesel is needed as is the Case when training with genuine machines, and there is no tyre or engine wear. The investment pays off quickly.”

The training simulators have genuine Controls from Volvo excavators and wheeled loaders, making the training very realistic so that students get an authentic machine experience.

The simulators are refined and developed continuously by Oryx Simulations by creating additional options, amongst other things. In this way the investment is future-proofed and it will be possible to add new training exercises.

“In addition, the training simulators are available for all markets in the world since we’ve had them language-adapted: there are several languages included, but we can also help customers with languages of their own choice in the simulators,” adds Jacobson.

Other equipment manufacturers have also unveiled simulators, including

The SmartROC T simulator uses the original Controls identical to those on the drilling equipment to provide students with a realistic training environment.

“The advanced control system is also integrated into the simulator, giving students the opportunity to use all the features of the actual drilling equipment,” says Atlas Copco.

“Furthermore, the simulator has a pre-designed learning pass to give students step-by-step instructions on operational best practices. The simulator is mounted on a motion platform for a realistic experience.”