The new BlastMetriX UAV program from 3GSM allows quarries and mining operations to take advantage of unmanned aerial vehicle (UAV) technology to quickly, safely an accurately capture three-dimensional face profiles for enhanced visualisation of the blast area. The flexible system is the right tool for surveying large blast sites and does not require the use of propriety UAVs. This allows operations to use existing drones in their fleet or locally source drone equipment to take surveying images.

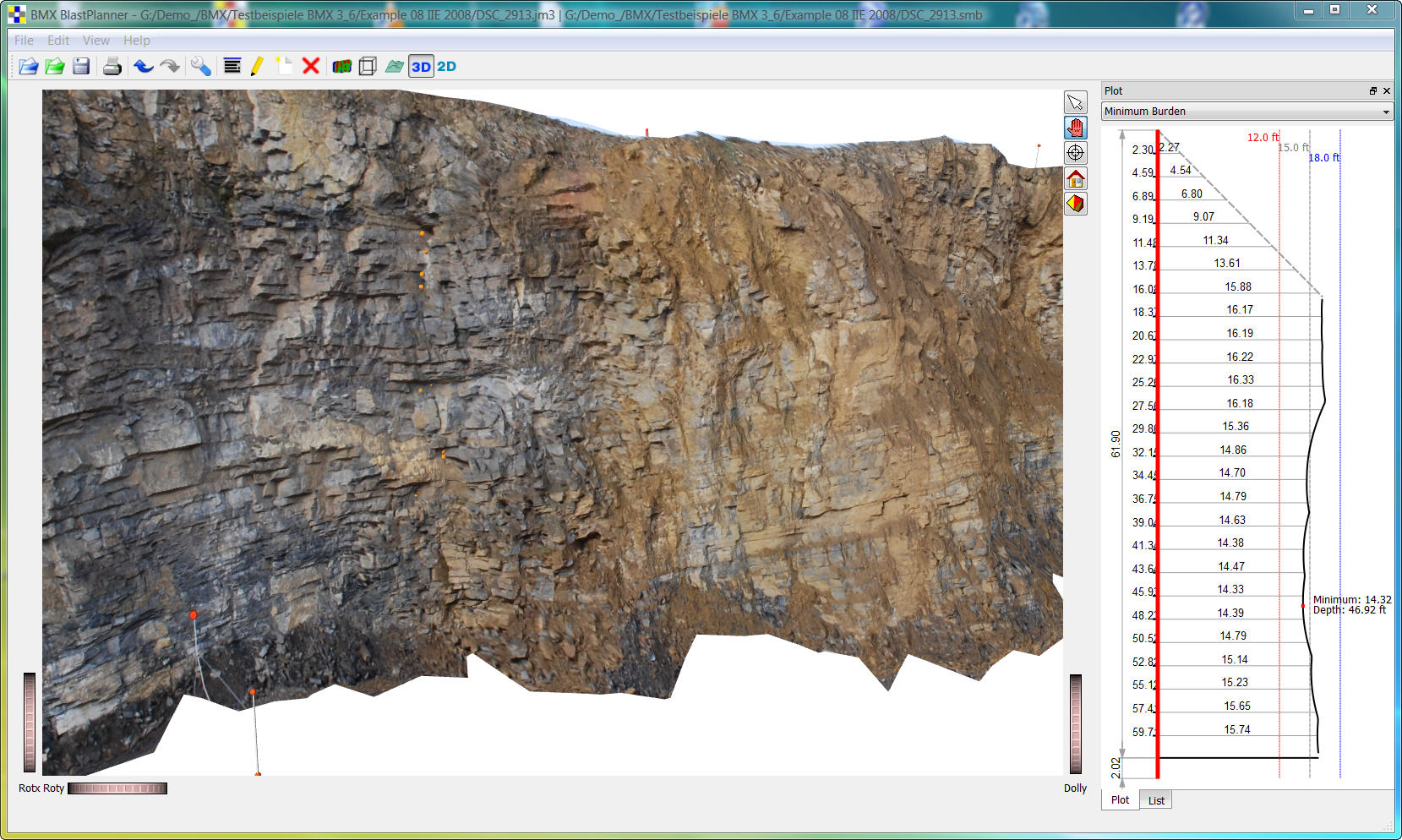

The system requires only the use of aerial targets or the standard BlastMetriX 3D targets as reference points. The low-flying UAV captures multiple data-rich overlapping images to generate hundreds of thousands of data points for accurately characterizing typography of the surveyed area and creating a three-dimensional profile of the face to ensure blast safety and performance.

New users can order a standalone BlastMetriX UAV system that includes all necessary software for UAV surveying and blast design. Alternatively, existing BlastMetriX 3D users only require a simple software upgrade to quickly integrate the usage of UAVs into the surveying capability. It gives operations the flexibility to conduct surveys using either aerial multi-photo images captured by the UAV or terrestrial images from a calibrated digital single-lens reflex (DSLR) camera. This enables surveying operations to continue regardless of no-fly-zone restrictions or inclement weather.

Since BlastMetrix UAV does not rely on Cloud data storage, all surveying and blast design work can be efficiently managed in the field. All captured images are downloaded directly to the computer, allowing BlastMetriX users to efficiently produce a blast design. The designed blast can be georeferenced and data sent directly to smart drills, improving drilling accuracy and driving down costs.

-continued-

The BlastMetriX UAV system gives technicians the confidence the blast will perform as designed to mitigate flyrock issues, high air overpressures, excessive vibration, poor fragmentation, subpar cast, loss of grade control and wall damage. As a result of blast design optimisation using BlastMetriX UAV, operations can realize significant benefits including improved fragmentation, higher crusher throughput and lower drilling manpower requirements.

The new BlastMetriX UAV system gives operations advanced analytical tools for measuring blast performance, so programs can be optimised. BlastMetriX UAV offers pre/post blast comparisons, pre/post excavation reporting, muckpile quantification – movement, volume and swell – and power trough analysis.

The scalable BlastMetriX UAV software allows companies to integrate as much or as little technology as required. Its capabilities can be expanded to meet an operation’s growing needs. Professional service, support and training of program use are provided by RAM, Inc. of Powell, Ohio. Additionally, RAM, Inc. conducts UAV ground schools to teach operators how to fly UAVs, prepare students for taking the FAA 107 pilot’s test and to help operations maximise use of UAV surveying technology.