Guests got their first glimpse of the new machines – which consist of the 41tonne (45ton) R45D, 54tonne (60ton) R60D, 65tonne (72ton) R70D and the flagship 95tonne (100ton) R100E – on Tuesday 10 April. The star of the show was the R100E, a completely new rigid hauler that combines a wealth of market and customer knowledge with proven components, new technologies and a striking new design – all providing a cost-effective and productive solution to fulfil the needs of today’s mining and quarrying customers. The new four-model range is initially available in less regulated markets.

With a focus on helping customers achieve production targets faster – and using less fuel in the process, Volvo Construction Equipment’s (

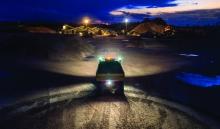

As well as having the chance to inspect the new machines, guests at the 9-11 April landmark event are also getting to the opportunity to test drive the all-new flagship R100E, see how the rigid haulers are designed and made and watch them in action at a nearby quarry.

With customer input key to the development of the new range of rigid haulers, the machines have undergone extensive field testing – with very positive results. One such customer is Trollope Mining Services, a contract mining company based in Johannesburg, South Africa.

“The Volvo R100E is an impressive design that offers a good balance between productivity, fuel efficiency, comfort, ease of maintenance and safety,” says Sagrys De Villiers, site manager at the Manungu Colliery. “We are sure that this truck will be a strong competitor in the rigid truck market in the future.”

“The R100E is capable of carrying an extra bucket pass compared to other 100 ton trucks being used on the site,” agrees workshop manager Danie van Niekerk. “This means extra productivity for the mine, which is very valuable. Speed and acceleration of the hauler on inclines compares favourably against competitor machines, even when fully loaded and carrying more material.”

The E-Series R100E is a completely new machine that delivers stability, a long service life, high profitability, durability and comfort. With its high capacity and hauling speeds, new V-shaped body, efficient hydraulics, intelligent monitoring systems and operator environment, Volvo CE demonstrated how the rigid hauler will help customers in the mining and quarrying segments move more material in less time. Moreover, the R100E is also quick and simple to operate and maintain.

Based on the existing and well-proven

“It was great to invite customers and dealers to the site where the new Volvo-branded rigid haulers are being manufactured,” says Thomas Bitter, senior vice president of the marketing and product portfolio (MaPP) function at Volvo CE. “We’ve been working on the new range since Volvo CE acquired Terex Trucks in 2014. The development of these machines has relied heavily on the longstanding rigid hauler expertise of Terex Trucks as well as customer input and the technological strength of the Volvo Group.”

“The proven design of the Terex Trucks rigid haulers provided us with a strong DNA on which to develop Volvo CE’s innovative entry into this product line,” agrees Paul Douglas, Volvo CE’s vice president of rigid haulers and managing director of Terex Trucks. “The R100E has been designed to meet customer demands for a rigid hauler that delivers high performance and productivity, low total cost of ownership, easy serviceability and good operator comfort. It, along with the rest of the range, builds on Terex Trucks’ 84-year heritage and incorporates the customer feedback and market knowledge we have built-up over the years.”