The US headquartered company says the system utilises predictive analytics to enable aggregates, mining and cement operations to remotely gather critical insights that optimise belt conveyor productivity and heighten operational efficiencies.

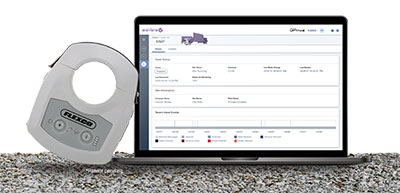

Elevate is a wireless platform that transfers data insights to an intuitive cloud-based dashboard via edge technology, which Flexco says allows remote monitoring of belt cleaners. The intelligence it gathers grows over time and the platform is designed to simplify and accelerate belt maintenance using its data-driven engine.

Flexco Elevate was created in partnership with Uptake, an industrial AI and IoT data science company. Flexco says the platform reduces the need for on-site inspections and allows operations to access real-time insights remotely from an intuitive dashboard, so users can quickly address belt conveyor performance issues and minimise unexpected downtime.

Setting up the system starts with the installation of an Elevate i3 Device to the end of each Flexco belt cleaner where analytics are immediately aggregated and processed. The information is then wirelessly transferred to the Flexco Elevate Dashboard where operations have immediate, remote access to action-oriented insights and service information for all of the Flexco cleaners throughout the operation.

“With the introduction of Elevate, Flexco is reimagining the ways customers can enhance their operations through innovative solutions and added value to belt cleaners and other conveyor components,” said Ryan Grevenstuk, Flexco director of global heavy-duty marketing.

“Because it has the power to turn complex data into real-world outcomes, Flexco Elevate is able to transform the way operations address pain points – allowing them to make proactive decisions that continually maximise their uptime and productivity.”