Drill rigs, rock excavation and construction equipment manufacturer

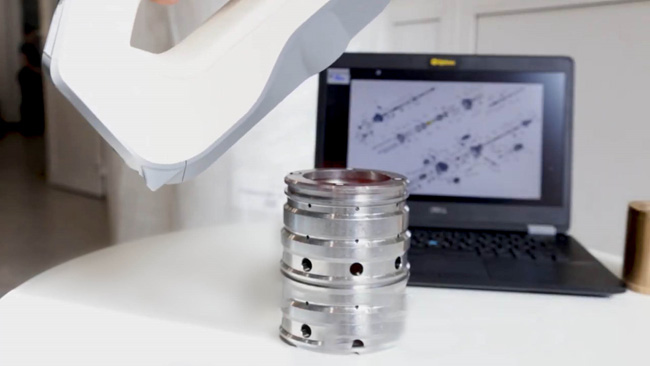

Epiroc says that technology enabling additive manufacturing or a phased build-up of an object using 3D modelling and printing has still not been widely developed for the mining and construction industry, but that it is gaining momentum. The technology of fast details production involves the manufacturing of physical samples based on CAD data or 3D-scanning data. This includes the use of special equipment for layer-by-layer 3D-synthesis and practically no need of further refinement.

Earlier this year Epiroc started to explore the opportunity to implement additive technologies in the process of manufacturing spare parts, ensuring high standards of quality and accuracy.

“Working with 3D technologies opens up unlimited opportunities for the company to create complex geometric shapes and maintain high-quality standards,” said Epiroc product manager Anders Johansson. “This technology does not only provide additional opportunities for the creation of complex parts. It also allows companies to transfer digital models around the world in minutes to manufacture spare parts right on the spot where they are needed.”

Epiroc says its equipment users will see waiting time for spare parts supply noticeably reduced, and consequently, equipment downtime will also decrease. It adds that 3D printing could significantly optimise the process of delivery and storage of Epiroc spare parts, which will lead to increased value for customers.