Komatsu president and CEO Tetsuji Ohashi and Trimble president and CEO Steven W. Berglund have announced a collaboration to improve customers’ ability to exchange 3D construction site data between Komatsu and Trimble construction software, making managing mixed earthworks fleets easier and allowing for a more holistic view of site operations.

As part of the collaboration, Trimble and Komatsu are working together to develop an Application Program Interface (API) to enable compatibility between their software platforms. Komatsu’s KomConnect platform and Trimble Connect software, a cloud-based collaboration ecosystem, will share digital construction data that can significantly benefit contractors and project managers.

The collaboration is in response to customer demand for mixed fleet interoperability as well as support for Japan’s i-Construction initiative, a plan to drive innovation and revolutionise productivity on construction sites through the use of information and communications technology (ICT), promoted by the Ministry of Land, Infrastructure, Transport and Tourism.

Komatsu introduced SMARTCONSTRUCTION, an Internet of Things (IoT) solution for construction site operations, in Japan in 2015. The solution enables customers to visualise site operations using ICT about workers, machines and surfaces on the KomConnect cloud-based platform to create a safer and more productive site. The solution has been introduced to 3,300 jobsites so far.

Trimble Connected Site solutions provide contractors a complete view of site productivity including materials quantity and movement, volume and compaction data, and fleet and asset management information, regardless of machine make or model. Trimble Connect is a collaboration environment allowing customers to combine and share data from multiple sources, including those from outside of the Trimble ecosystem.

Komatsu will continue its efforts to extend the openness of KomConnect platform to respond to customer demand in collaboration with SMARTCONSTRUCTION partners.

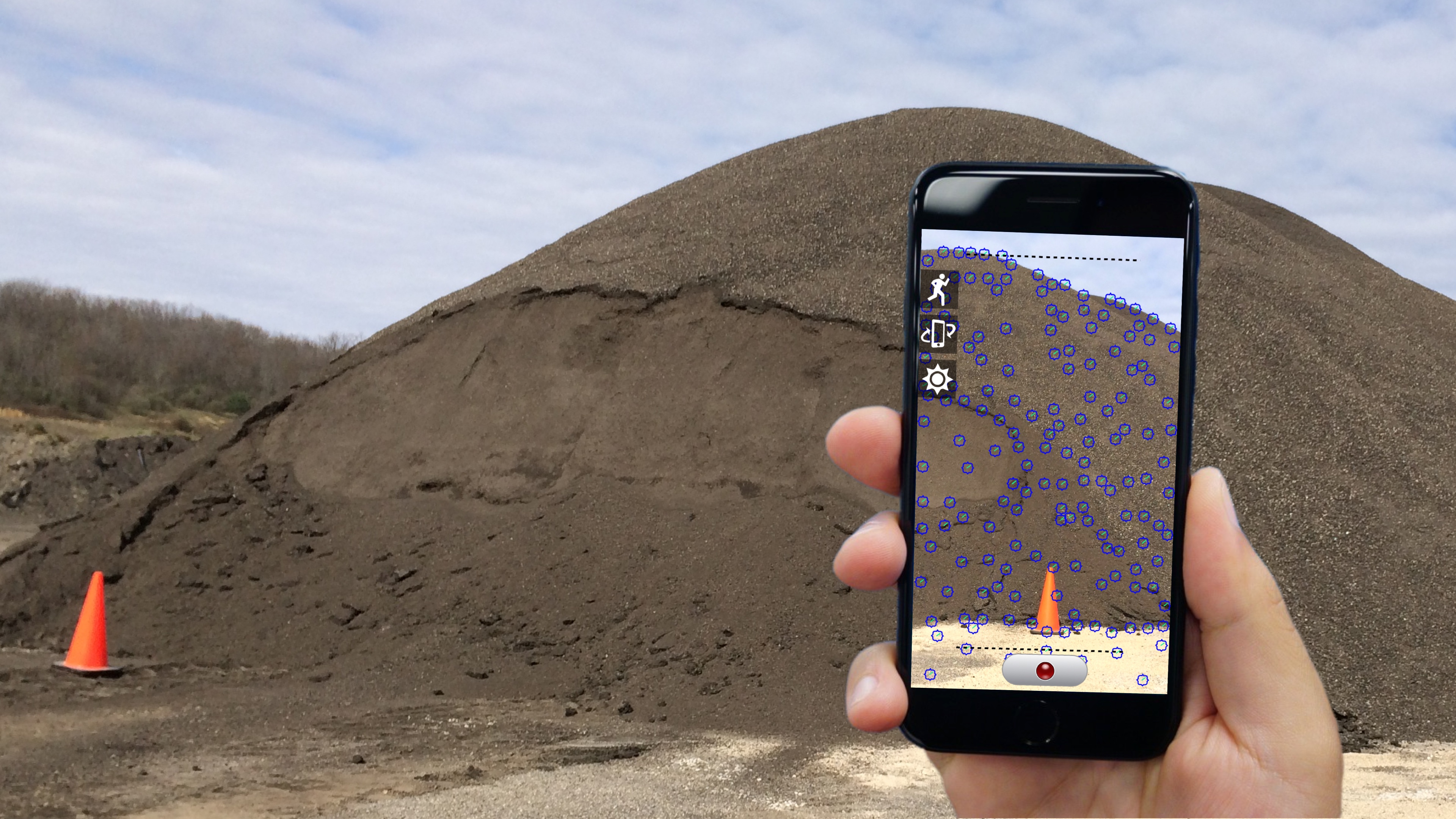

Whether it’s a delivery of aggregate or a mound of spoil, any stockpile can now be quantified by pointing an iPhone at it and walking around using Stockpile Reports’ Lite iPhone app.

The company says the app has been produced to enable construction professionals to measure piled material themselves for a small fraction of the typical cost, getting measurement results quickly.

“We’ve been serving the large enterprise construction materials industry around the world since 2012, with our inventory management platform,” says David Boardman, CEO of Stockpile Reports.

“Now we’re making our patented measurement technology available to everyone.”

After downloading the app (search ‘Stockpiles Lite’ in the App store), users point the iPhone camera at the surface of the pile and walk around its perimeter. The app captures high-resolution imagery that is then uploaded to the cloud and processed to generate a report.

According to the company, independent tests are said to have shown the measurements to be within 1% to 2% of LiDAR (laser measurement) surveys.

“We’ve rolled out the app out to the UK, Ireland, South Africa and New Zealand, and will be expanding it to a worldwide audience throughout the year,” says Tony Jacobson, vice president of Product at Stockpile Reports.

“The app was designed to work with free-standing stockpiles up to 3,000 cubic metres.”