“We responded to requests from customers and took a major step towards increasingly digitalized, transparent and more productive worksite systems for infrastructure construction,” says Tuomo Pirinen, application expertise manager with Surface Drilling and Exploration division at Sandvik Mining and Rock Technology. “The new solution creates a link between our OEM fleet management and 3rd party mixed-fleet cloud systems, to make work easier for contractors, design engineers as well as equipment operators. The idea is to hook up with systems that companies already use, to reduce unnecessary complexity. Sandvik is excited to be the first equipment OEM to offer this interoperability with Infrakit Cloud.”

The new solution creates a flow of communication between Sandvik drilling equipment, the SanRemo information management system and Infrakit Cloud. This way the process data generated by onboard automation and TIM3D drill navigation systems can be easily shared with contractors’ and civil engineering companies’ other systems. Thanks to this new solution, data only needs to be uploaded once from the rig, after which it is automatically shared into the Infrakit Cloud. This allows to share the data with as many other systems and users as necessary, eliminating the need for multiple uploads or manual transfers of data.

A major benefit is the ability to share project data with all the relevant systems and parties: design engineers, drill planners, drill operators, production managers, client’s supervisors, to name a few. Everyone can also easily access the information they need on-site, eliminating the use of USB drives and issues with multiple file versions. All the necessary data is available in the cloud, everywhere and at all times. The cloud storage also serves as a permanent archive for any future use.

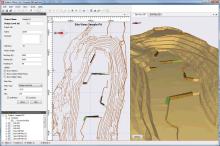

Data generation on the drill rig is built on the Sandvik TIM3D drill navigation system. TIM3D allows pre-designed drill plans and surface models to be uploaded onto the drill rig, and even to be created or edited on the rig (TIM3D availability and features depend on the rig model). During and after drilling, the rig stores as-drilled information, driller’s notes, and Measurement While Drilling (MWD) data for reporting, quality control and downstream process planning.

The connection between SanRemo and Infrakit Cloud is created by a cloud-to-cloud connection, building on API (Application Programming Interface) technologies. The drill rig connectivity is based on mobile data via GSM networks. The current pilot solution enables push of data from SanRemo to Infrakit Cloud. Uploading options already existing in SanRemo will be made possible in the future through Infrakit Cloud as well.

“At Sandvik, we are committed to digitalisation of worksites and mines. We want to offer the maximum productivity, including connectivity and other value adding digital features for the users of our drill rigs. To this end, we will fully support our customers, third party service providers, and other OEMs to capture the digital potential of our drilling products,” Tuomo Pirinen summarises.