Norwegian surface drill and blast contractor Inge Hjelle Entreprenør Forretning is using Sandvik Construction’s Driller’s Office to enhance the firm’s performance. The powerful data management program is said to improve surface drilling performance, and has become a key aid in enabling the company to improve its customer service. Guy Woodford reports.

Alexander Hjelle established Inge Hjelle Entreprenør Forretning (IHEF) in the late 1970s. The company now operates from Hagavik, south of Bergen, focusing on surface drilling and blasting solutions in its region. This tight focus on both location and specialism are part of Alexander’s strategy of ensuring his company is the leader in its field. Although tightly focused on one geographic area of operations, the company also has a number of small satellite offices located to assist work on specific projects. This includes ancillary work such as cuttings for roads, and also portal excavations for the new Ulriken rail tunnel project. The latter is being constructed by a joint venture of

To service his customers’ needs, Alexander’s surface drilling is delivered by three

As both a successful business owner and entrepreneur, Alexander has emphasised the use of the very latest tools in order to deliver a more efficient and effective service. As such, Alexander has been keen to learn of any new developments which could help the performance of his business, and hence the service he supplies to his customer base. Through the close working relationship that has been developed over the years with Sandvik, Alexander became aware - and an early adopter - of the powerful new data management system for surface drilling – Driller’s Office – which is now used in tandem with Sandvik’s well-proven SanRemo service.

Originally, Alexander discussed with Sandvik the possibilities of introducing more sophisticated data management in surface drilling, similar to those enjoyed in tunnelling. Sandvik advised him that ‘something is on the way,’ with these early discussions leading to what would evolve, through collaboration, into Driller’s Office. While initially focused on drill plans, Driller’s Office’s capabilities grew. Alexander feels his feedback and dialogue with Sandvik helped to expand this offering.

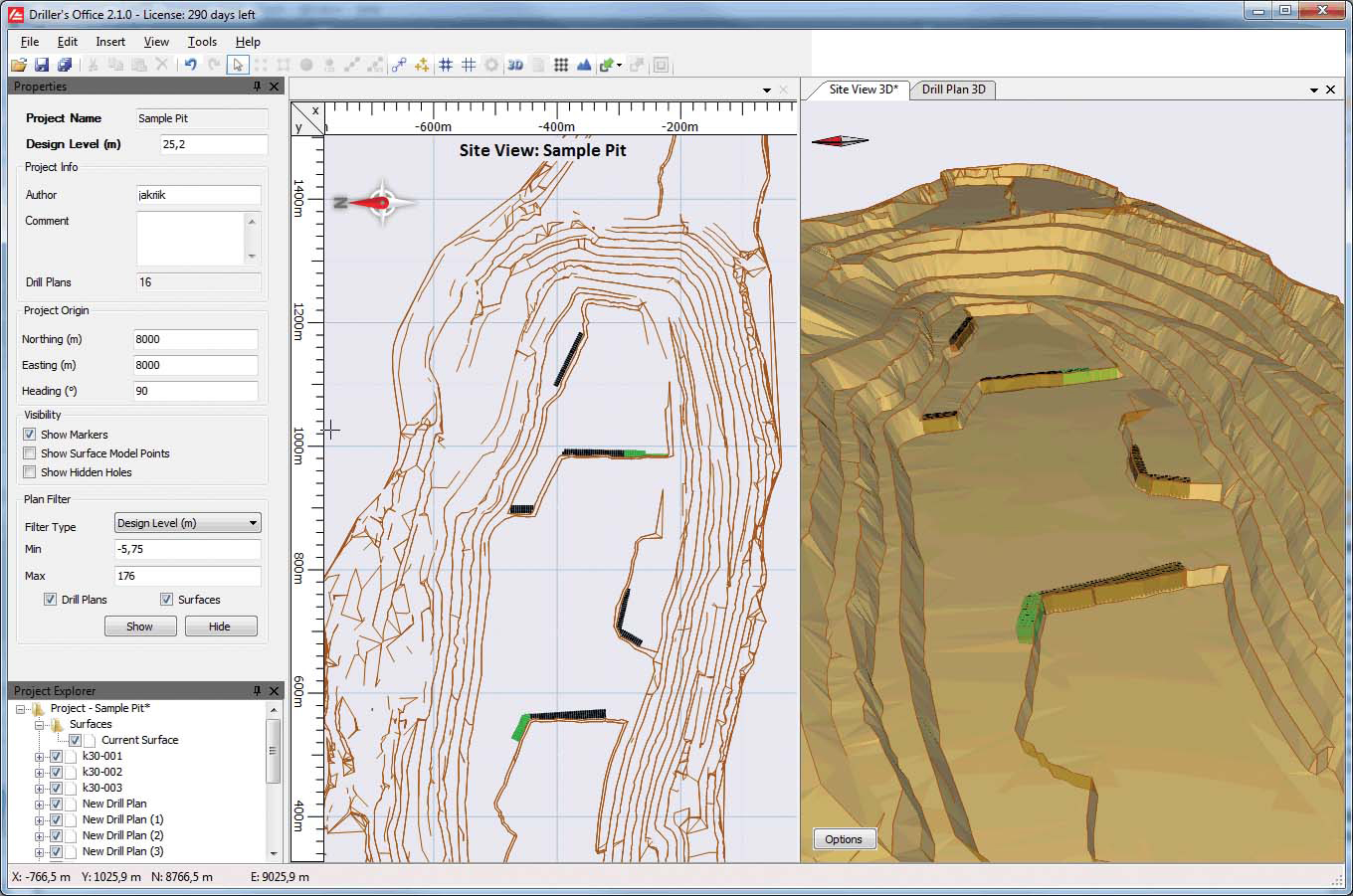

Sandvik’s aim in developing Driller’s Office for surface drilling was to boost drill plan design, data management and reporting. The package features simple visualisation tools for both the drilling pattern and terrain models. The program has a ‘Drill Plan Editor’ function that enables individual adjustments to hole positions, floor level, inclination, direction and other factors. It also allows data from a site’s actual bench shapes and forms to be included.

Data from the site comes back to the user’s office in real-time via the SanRemo service, which is located within Driller’s Office. All of which is said to improve accuracy, quality and the end result. It also improves efficiencies in terms of time and money in executing tasks. Through the program’s reporting tools, the user has all the necessary information and data to provide others in the supply chain – the main contractor and project developer for example – with the details of hole coordinates and drill plan against the confirmed outcomes. The latter is made possible due to the navigation control technology TIM3D.

The introduction of TIM3D has been an important development, adding what is possible in surface drilling. This gave an added degree of control and accuracy that Alexander says, “Was so much better.” He adds: “It formed the basis for going forward in data management.” With TIM3D delivering control at the rig, Sandvik’s well-proven SanRemo service feeding back data, and now Driller’s Office quickly and easily managing the information during a job, Alexander believes that the Sandvik solutions let him go further than before. “Without Driller’s Office we can’t do the activities how we want to,” he explains.

Offering fast and accurate management in the flow and control of office-to-field communications, Driller’s Office has quickly become integral to of IHEF’s operational performance and service delivery. The program is now helping Alexander transform his operations and ensuring that his customers benefit from more efficient and productive drill and blast operations.

Driller’s Office has effectively enabled Alexander and his team to readily access important data before, and during, field operations. This enables them to adapt to changing circumstances practically and quickly. As such, Driller’s Office enables the company to achieve greater speed and productivity on any job, while ensuring that drilling accuracy can be readily confirmed. Alexander has been impressed by the benefits the program has delivered on its current projects, and believe the benefits will be even greater on larger jobs coming up.

Alexander readily acknowledges Driller’s Office is now a lynchpin in his evolving business process system. Before any rigs are on site, members of the surface drilling team input design data into the program. The approach is then to plan around those design points, working with survey data to establish a practical drilling plan. “We do this week’s before the rigs start drilling on site, which is different and a great business advantage,” says Kjetil Jørstad, the company’s surveyor.

By developing a unique and practical drilling plan, the approach is to focus on buildability that will easily, and in a pre-planned way, ensure delivery of the correct design alignment. It does so in Driller’s Office by setting, alongside the design alignment a fairly uniform ‘constructability margin’ – the outer edge of which is a fixed offset from the design coordinates. The offset data is then fed to the rigs, where TIM3D guarantees the delivery of the drill coordinates, and also helps to ensure productivity from the plant onsite.

On first becoming familiar with Driller’s Office, and in joining the program testing, Kjetil could immediately see the potential for both productivity onsite and improving business processes. He says, “The drilling is more correct, meaning the holes are more correct and, consequently, fewer holes are needed to achieve lines wanted for the constructability margins.” He adds, “The difference can be seen easiest in very big blast patterns. On each part of the project there are benefits in terms of business process continuity. The productivity benefits will become more pronounced on the bigger jobs coming very soon.”

For IHEF’s business processes, though, for the moment, there is a last step – billing – that still needs the existing systems familiar to the regional construction sector. Alexander Hjelle and Kjetil Jørstad see scope for change once main contractors and clients become more familiar with how the system confirms what has been done on site. They will then increasingly accept what real-time data is telling what is being achieved in delivery to design alignments. Then, Alexander believes, there is potential to have reliable build data without requiring external surveyors.

Moving from old to new business process systems will happen in steps, realigning the chain of various programs being used, but with Driller’s Office at the core. “It is a key part of the business process system – a key step,” Alexander says. By running his old and new business process systems in parallel for a time, Alexander and his team will enable the main contractors and clients to compare them and their results. To Alexander, it’s all part of continuously improving his business by cutting out unnecessary time consuming or costly steps. The benefits are achieved – and shared in the supply chain – one project at a time. Then, gradually, the success can lead to shift in practices in the market.