RSSKieswerk Kohler has addressed the issues caused by excess fines in the material at its quarry in Engen/Welschingen, Germany.

The solution offered by CDE GmbH (

The raw material being processed by Kieswerk Kohler at the site contains a large proportion of material smaller than 250 microns. With the crushing and screening processes previously employed on the material, the sand was out of specification for use in concrete.

“This was causing a problem as local concrete manufacturers are my main customers,” says owner Thomas Kohler.

“I had been working to develop a system which would allow production of concrete aggregates, especially sand, so that it would meet the requirements of the European standards. The solution offered by CDE GmbH has also enabled the production of an additional saleable sand product which I can now offer customers”.

CDE GmbH in Heimertingen was formed in December 2012 and represents a development of the previous distributor agreement that was in place for Southern Germany with Jurgen Koelsch GmbH.

Stefan Koelsch director of CDE GmbH, explains the rationale for the formation of the new company.

“CDE GmbH gives washing a new focus in Germany. This ensures that we are able to offer aggregate and construction material manufacturers a level of washing expertise, as well as project management capability and service support that is only available when construction materials producers buy direct from the manufacturer.”

In seeking to address the issues raised by the large proportion of minus 250 micron material in the sand and gravel feed, Kieswerk Kohler was investigating the option of washing the material after the initial dry screening process.

“We were thinking about several different options and ways in which we could correct the gradation curve of the sand in order that it met the required concrete specification,” says Thomas Kohler.

“When we explained the issue to CDE they came up with a solution very quickly and since it has been introduced the plant is doing exactly what I wanted it to do.”

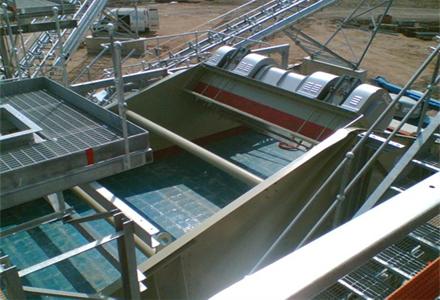

The processing system introduced by CDE GmbH in Baden-Wurttemberg includes the M2500 E4 mobile washing plant and the AggMax 83 portable logwasher. In addition to the problems caused by the excess fines, content in the feed material Kieswerk Kohler was also faced with clays and silts which the dry processing system was not able to effectively remove.

It was revealed that by introducing the AggMax the quality of aggregates produced would also be improved, a solution that also helps to maximise sand production from the washing plant.

“The attrition process within the AggMax plant’s logwasher liberates a lot of valuable fines that would previously have been destined for the aggregate fraction. By aggressively scrubbing the material and returning the liberated fines to the sand washing plant we are ensuring that Kieswerk Kohler recover the maximum amount of sand from the material while also enhancing the quality of the washed aggregate products by removing these fines,” says Koelsch.

The sand and gravel feed is delivered to the M2500 washing plant by loading shovel and operates at 100 tonnes/hour The plant accepts 0-100mm material with a grid on the feed hopper rejecting any oversize. The feed material is then delivered to the M2500 aggregate screening phase which is achieved using the integrated Prograde P2-75 rinsing screen.

The top deck of this screen separates at +32mm and this material is sent to stockpile via one of the integrated wing conveyors. The bottom deck separates at 4-32mm and this material is then sent to the AggMax for scrubbing via the integrated Rotomax RX80 logwasher. Once material has been processed by the Rotomax it is discharged onto a triple deck horizontal sizing screen which classifies the aggregates into 4-8mm, 8-16mm and 16-32mm.

The 0-4mm material collects in the Prograde screen sump and is pumped to the integrated Evowash sand washing plant whose screen is split to allow the production of two sand grades: – 0-4mm concrete sand and another 0-2mm product.

“The creation of the additional 0-2mm sand product was required as there was too much of this material in the 0-4mm range. The sand washing phase is configured to remove up to 25% of the 0-2mm material from the 0-4mm product to allow for the production of concrete sand,” says Koelsch.

RSS