Growth of Poland's aggregates sector has been driven by EU funding in recent years, making it an interesting market for acquisitions by Europe's big quarrying groups. Adrian Greeman reports

After a slack period in the early part of this decade, Poland has seen some steady growth in its aggregates market in recent years.

Medium size private companies and some larger players have opened new pits and quarries though, as everywhere this is becoming more difficult with new rules on environment and local community pressures. Poland has found that the other side of the European Union coin is that Brussels' regulations must be imposed as legislation comes into line with other countries in Europe.

This growth has added impetus to the industry and Poland is in the process of setting up a national aggregates federation, the Polish Chamber of Mineral Aggregates. An initial meeting was organised for early September this year in Augustów in the north-east.

Geology

The country is a rich area for aggregates with extensive deposits of natural sands and gravels throughout, and particularly in the flatter centre and northern regions. It also has substantial resources of sandstone and limestone deposits for crushed rock aggregates.

Private performance

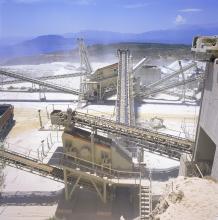

A number of new quarries has been opened by medium size firms in recent years, some for general purpose and many to service major highways and other projects. A typical example is

When owner Eugeniusz Wojak acquired the firm it was involved in land reclamation and redeveloped it. He moved it into wider areas including metalwork, woodwork and transport services, and wider civil engineering with eventually adding hydraulics and pipeline work. Quarrying is a late addition with a first pit opening in 2004 in Charzewice producing aggregates for road production and especially asphalt.

Some 19ha of a potential 69ha is being exploited and, after modernisation in 2007, it is one of the largest modern plants in the region producing around 6000tonnes per day. It is permitted to 2035 and may get further extensions then.@A second quarry opened last year at Mecina, 15km from Limanowa, for sandstone used for river regulation projects, construction and roads. The potential of the quarry is not fully explored but it currently produces 1000tonnes per day but at full capacity it could exceed 5000tonnes per day.

The Mecina quarry currently uses two large dump trucks; three smaller dump trucks; two wheel loaders including a Hitachi ZW310 (delivered six months ago); and five excavators including three

The output from both quarries is used locally and also delivered to the nearby city of Katowice. One major motorway project has reached here from Germany and will be extended to Poland's eastern border, another is coming southwards, which means that demand is likely to remain high for Wolimex's aggregates.According to Polish Geological Service geologist Tadeusz Smakowski, who specialises in the aggregates business, the most important deposits are glacial natural aggregates, originating from the so-called north Polish glaciation which covered part of the country during the ice ages.

Describing the country's geology, Smakowski said that around another 40% of those glacial reserves occur in the river valleys of the Carpathian and Sudetes mountains which are both in the southern part of the country.

He added that there is also a small amount of sea-won aggregate at the Slupsk Bank on the Baltic Sea. Sand and gravel is either used directly with washing and sorting or is crushed to size it and improve characteristics for construction and concrete use.

According to the Minerals Yearbook of Poland 2007, which Smakowski co-authored, there are 6029 recorded useful deposits of natural sand and gravel aggregates in Poland, containing just over 15000million tonnes of reserves. Of these 1607 deposits were exploited, while a further 1457 were abandoned.

Quarried rock for natural crushed aggregates is extracted mainly in the southern parts of the country, particularly in Lower Silesia with over half the domestic reserves, though there is some 22% output in the Swiêtokrzyskie Mountains, another 13% in the Carpathians around 9% in the Silesia-Cracow region.

The Minerals Yearbook states, "Total reserves of crushed and dimension stone deposits amount to 8731million tonnes, in 624 deposits excluding limestone for lime and cement production, dolomites for metallurgy and ceramics, phyllite-schist, mica-schist, or quartz-schist".

Hard rocks are also extracted including high quality granite, basalt, and melaphyre in the southern part of the country and a rich variety of other types.

Like most countries Poland primarily uses road transport for local delivery though there is a certain amount of rail transport over longer distances particularly of some higher grade crushed rocks from the south.

"About 15% is delivered by railway," said Aleksander Kabzinski, an analyst at the consultant Polski Zwiazek Pracodawców Producentów Kruszyw, which is the UEPG member for Poland. "There is a small amount of shipping transport on the Baltic coast as well."

Production

Construction use of aggregate output splits roughly 70% into building work and 30% for roads in both concrete and asphalt, according to Kabzinski. Nonetheless, this can be quite variable across regions, influenced by some very large highways works in recent years that were carried out both just before and since the accession to the European Union, which provided infrastructure development funds.

The companies that are involved in aggregate production in Poland are also mixed with a large number of small firms but also some major players, including international firms such as

According to the Mineral Yearbook, the largest companies producing natural aggregates are: Olsztyñskie Mineral Mines, owned by CRH plc (Ireland), Górazdze Kruszywa producing group (consisting of Zielonogórskie Mineral Mines, Opolskie Mineral Mines and Bialostockie Mineral Mines), Tarmac producing group (Wroclawskie Mineral Mines and "Kosmin" Mineral Mines of Lódz), Lafarge Kruszywa producing group, three workers' companies: Szczeciñskie Mineral Mines, "

The size of sites is generally smaller than in Western Europe with only 17 gravel pits producing over 1million tonnes in 2007. There are around 45 plants with an output of between 0.5 and 1million tonnes per year, while another 246 produced 100,000 to 500,000tonnes. However, about 71% of the total number of quarries in Poland produce less than 50,000tonnes per year.

Crushed rock aggregates are delivered by 130 companies and over a third of which are small operations with an annual production of under 100,000tonnes per year. More than 80% of crushed aggregate supply in Poland comes from the 20 large companies that extract over 500,000tonnes per year each. Multi-plant companies with more than three quarries are rare.

Rising demand

Production of all aggregates has increased steadily in recent years following a fall in production at the turn of the century before Poland joined the European Union.

Estimated figures for sand and gravel are given by the yearbook as the official statistics only include companies with over ten employees. According to the yearbook, overall mining output levels reported by Mineral Resources Datafile are 139.4million tonnes in 2007, against official production data of 71million tonnes. Estimated production from the Datafile figures suggests a growing output from 2002 onwards for natural sand and gravel aggregates culminating in 133million tonnes in 2007.

Recycled aggregate in the form of crushed concrete is gaining some ground but is limited in significance at present. Smakowski said there may be use on sites which does not show up in statistics.

Crushed rock production is lower than sand and gravel but was a healthy 46.9million tonnes in 2007, a record year after substantial growth from 2002 onwards.

There was a downturn between 1999 and 2002 when a production of crushed aggregates, which had climbed to 30.3million tonnes in 1999, fell back to 26million tonnes per year, as a result of a crisis in construction sector. "There was also competition for domestic aggregates from wastes and imported crushed aggregates," said Smakowski.

New quarries have opened to help meet the rising demand but as with most European countries, the regulations for environmental protection and restitution are becoming more severe.