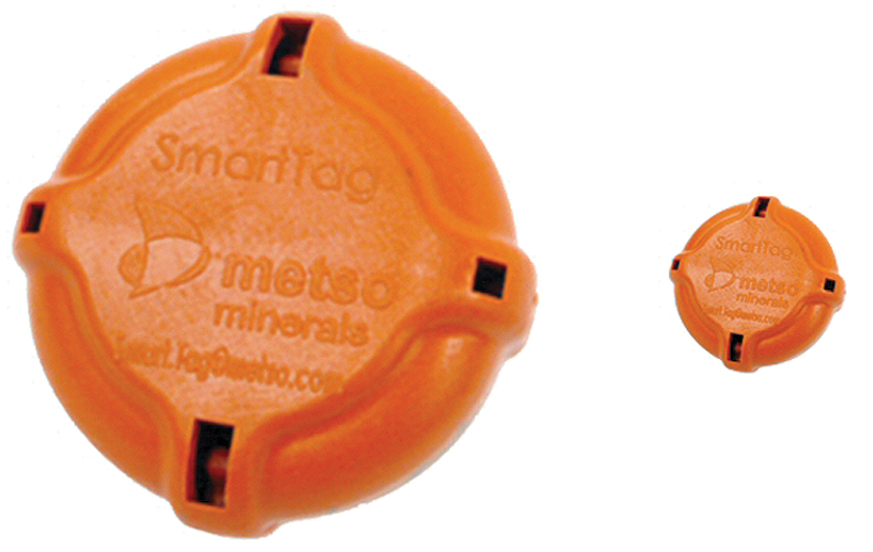

Special tags for tracking mineral materials have been significantly reduced in size: even smaller ones are on the way

A tracking technology, designed to travel through a mine or mineral processing plant in a series of simple steps, has been made smaller.

SmartTag, a 20mm RFID (radio frequency identification) transponder, was designed to allow tracking of material from its source through blasting, run of mine pads, crushers, intermediate stockpiles and into the concentrator.

The system was developed by

To increase the accuracy of this tracking, Metso PTI developed the SmartTag, and since its commercialisation in 2007 it has been used in the majority of PTI’s consulting projects and several permanent systems have been installed worldwide.

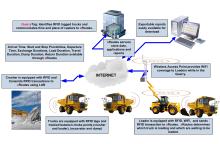

Initially, the tag and insertion location is logged using a hand-held computer or PDA, then it is inserted into the ore (for example, into a blast hole). The tag travels with the ore/aggregate through digging, transport and processing, before being detected at detection locations (on conveyor belts), when the time and specific tag is recorded. The RFID tag data is then loaded into a database and analysed as required.

To achieve this, the SmartTag system requires five main components. The PDA allows the initial RFID tag insertion process to become more efficient and accurate.

The next component, the antenna, is located at the conveyor belts, and this induces a charge on the tag and also receives a transmitted signal back from the tag, while an RFID reader then decodes the signal from the antenna and determines the identification of the RFID tag passing the antenna.

A data logging or buffer stage improves the reliability of the systems and also makes movable systems possible, but the core of the SmartTag software is an SQL (Structured Query Language) database. The database, located on a dedicated server, stores all the information about the detection points, detected RFID tags and original locations.

In the past five years there have been significant advancements with RFID technology, and this has allowed PTI to extend the reach of SmartTag from secondary crushing to tertiary crushing and beyond.

This has been achieved by drastically reducing the size of the tags from a diameter of 60mm to 20mm, which ”have been successfully used in several studies.” [These were outlined in a paper presented at the 35th APCOM Symposium 2011 in Wollongong, Australia, on which this article is based].

Claimed benefits of using SmartTag include linking spatial mine data to time-based processing data; increased confidence in mineral blending; proactive process changes for known mineral types; and accurate measurement of residence times in stockpiles and bins.

To expand the applications of SmartTag through and beyond secondary crushing, a mini RFID tag was required, and to incorporate such tags into the SmartTag system, PTI faced significant challenges, although Metso PTI says it has successfully incorporated a smaller, or mini, RFID tag into its SmartTag system.

“The changes to the system installation are minor and increase the reliability of the system as a whole. In several examples the mini RFID tags have proven to be, on average, more robust than normal sized RFID tags,” says the paper.

“The PTI team envisage that with the successful incorporation of the mini RFID tags into the SmartTag system it will allow applications for the system to be expanded. PTI is now working on proving the reliability of the next size of RFID tags, the even smaller micro RFID tag, which can pass through a 10mm mesh screen. With the decreasing size of RFID tags and the development of SmartTag into a truly distributed system, it can be extended to cover the whole minerals supply chain. Detection points can now be located in the plant, the port and even at the location of the customer.”