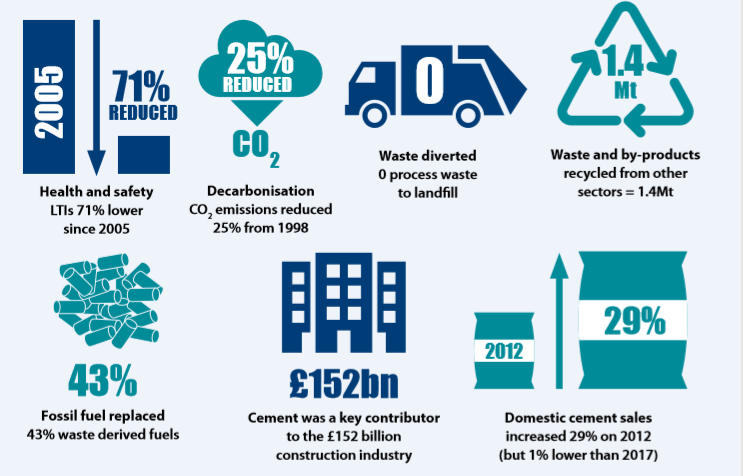

CO₂ emissions in the UK cement industry reduced by 25% between 1998 and 2018, according to the Mineral Products Association Cement Sustainable Development report.

The report states the reduction is largely due to the industry’s success in improving its carbon footprint by increasing energy efficiency, using alternative fuels instead of traditional fossil fuels, and utilising renewable energy sources.

In 2018, the MPA says it actively engaged with UK government environment department Defra on development of its Clean Air Strategy for England and the UK-wide National Air Pollution Control Programme, building on the industry’s investment in cleaner processes.

Recycling and resource use were equally positive in 2018 according to the report, with 1.4 million tonnes of waste and by-products from other industries being co-processed in cement production. Recycled content of cement was shown to be almost 10% due to the cement production process’s unique capability to recycle minerals and recover heat simultaneously (known as co-processing). Additionally, zero process waste was sent to landfill.

Dr Richard Leese, director, MPA Cement welcomed the report saying: “UK cement producers continue the long-term trend to improve their environment, health and safety performance whilst facing increased international competition and a recently challenging market.”

“It is clear that our stakeholders, customers and communities want further environmental action and our members are acting on that challenge. By continuing our transparency on environmental performance in this report and providing the UK economy with low carbon products, the industry’s aspiration matches those that we serve. In the years ahead the challenges will become tougher and will require coordinated effort from the industry, the supply chain, Government and its agencies. MPA is ready to play its part.”