Following the launch of the MPA Charter in 2017, MPA Cement’s Sustainable Development Report is now set out to align with the 7 MPA strategic priorities. In particular, this report highlights the positive contribution the cement industry made in 2017 on Health and Safety, People, Resource Use, Climate Change and Energy, the Natural Environment, the Built Environment, and starts by Communicating Industry Value.

The health and safety of employees, contractors, neighbours and customers is the number one priority. The cement industry is continually working to improve the health and safety of its employees, contractors and neighbours. Five areas for improvement have been identified in 2017: risk reduction during kiln shutdowns, improving knowledge on process safety techniques, better communication on health and safety issues and incidents, reducing dust exposure of employees and better quality root cause analysis of incidents.

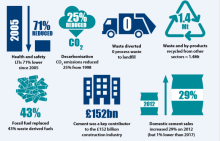

In 2017, the British cement industry used a huge 1.5 million tonnes of waste and by-products from other industries through co-processing. The cement industry’s valuable contribution to the circular economy was recognised for the first time in a 2017 Government report ‘From waste to resource productivity’ co-authored by Professor Ian Boyd, the Chief Scientific Adviser at the Department for Environment, Food and Rural Affairs (Defra) and Professor Sir Mark Walport (Government Chief Scientific Advisor).

The UK cement industry continues to be successful in reducing costs and improving its carbon footprint by increasing energy efficiency, using alternative fuels instead of traditional fossil fuels, and utilising renewable energy sources. In 2017 direct emissions of CO₂ per tonne from the UK cement industry were 25% lower than in 1998 and 0.4% lower than in 2016. Use of waste derived fuels increased to 44% of the thermal input, with waste biomass fuels composing 18.3% of the thermal input to the cement manufacturing process.

The cement industry has invested heavily and made considerable progress in reducing its impact on the natural environment. The majority (86%) of cement producing sites including kiln sites, quarries, grinding and blending plants and depots are covered by biodiversity action plans that ensure all mineral working sites are restored after use, often enhancing local biodiversity.

Dr. Richard Leese, Director, MPA Cement welcomed the report, saying: “This report highlights the continued commitment to sustainable development of our five UK Portland Cement producers. It demonstrates that UK cement production is at the heart of the UK’s circular economy by adding value, through recycling and recovery, to society’s waste. However, the industry continues to face strong competition from imports, not least because of the cumulative effect of UK environmental policies and taxation. With a supportive policy framework the UK producers are ready to supply the housing and infrastructure aspirations of a low carbon UK economy through the solutions that our downstream products can deliver to the built environment.”