One leading screening bucket company has launched an innovative new drum assembly solution for a wide range of its larger screening buckets, while another has recently invested in expanding its production capabilities. Guy Woodford reports.

The new TS drum assembly was developed a few years ago for the ALLU DL series meant for compact base machines (from 2-12tonnes). The amount of positive feedback encouraged ALLU R&D to develop the structure further to make it compatible with bigger ALLU D series screening buckets. The core of the ALLU TS technology are the blades that spin between the screening combs, and the end product size is defined by the space between the combs. The screening combs carry most of the material weight and this way the drums and bearings have less impact and load. This construction is clog-free and it ensures good capacity even with wet materials. The fragment sizes can be changed by just repositioning the screening combs. The sizes available are 16/32mm 25/50mm and 35mm. TS drums now available with TS drum assembly are compatible with 16–45tonne excavators and 7– 30tonne wheeled loaders. The TS drums are available with two different blade types: standard blades for different kinds of screening applications and axe blades when crushing effect is needed. The construction has patent pending.

The ALLU TS units have already proven their efficiency: The ALLU units equipped with a TS drum assembly and axe blades have been used at saw mills to process field bark. This material accumulates under the feeding conveyors and storage and classification areas. Field bark often contains sprigs, twigs, sticks, small log parts and stones and is therefore unsuitable to use, for example at power plants.

By processing the field bark with ALLU TS units, the material is crushed into smaller particles and the impurities are screened out. After processing, the material is homogenous and directly usable at power plants. Big and expensive screening stations that require vast operation and safety areas are not needed.

Chepstow Plant International based in Monmouthshire, southeast Wales, is said to have seen productivity soar after taking delivery of a DH4-17 ALLU bucket to crush and screen stockpiled clay marl down to -50mm.

The company has been so pleased with the results they have extended the hire contract with Finlay Hire.

The ALLU bucket, has been fitted to a 25tonne Volvo EC250 and has proved its worth out on a contract in county Leicestershire, England. It is said to be achieving results in excess of 100m³ an hour – even though the material is of a highly cohesive nature. John Carty, project support manager north of Chepstow Plant International, said: “We discussed our options with Finlay Hire and decided on the ALLU bucket.

“Initially we hired the plant for one month but decided to extend this to three due to the fact that it had been so successful. “We couldn’t be happier and the service and back-up that we have received from Finlay Hire is second to none.”

Finlay Hire, part of the

Established in the 1970s and now employing over 200 staff, Chepstow Plant International has been working with Finlay Hire for more than ten years – in this time they have both hired and bought plant.

Chris Bell, of Finlay Hire, said: “For soft rock crushing or difficult separation applications, where blockages and contamination are an issue, ALLU buckets are ideal.

“We can offer this solution to customers on every scale, from mini excavators up to 200tonne face shovel excavators.

“We have buckets to hire or demonstrate and can advise customers on the best model to suit their applications and base machine.”

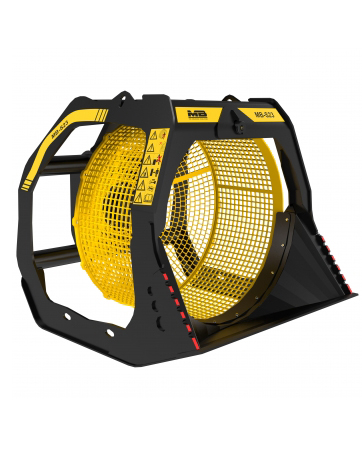

The addition of the INTERMAT 2015-launched MB-LS140 for skid-steer loaders brought

Of particular relevance to quarrying is the Italian firm’s MB-S18 for 20-35tonne excavators, and the MB-S23 for 35tonne plus excavators.

Usable prior to or after crushing, MB Crusher claims the MB-S18 screening bucket will reduce crushing time up to 60%, the MB-S18 also allows the screening of natural material (quarry residue, dry soil, and river stone) of any kind, making it convenient for on-site processing.

The MB-S18 can, says MB Crusher, be deployed with a novel intermittent system, a patented MB system said to improve results up to 30% compared to the traditional method and allows screening of wet material.

Marketed as the world’s largest screening bucket, the MB-S23 can be used with excavators greater than 35tonnes. Suitable for use before or after crushing, the MB-S23 screening bucket will, says MB Crusher, reduce crushing time up to 60%. The MB-S23 also allows the screening of natural material (quarry residues, dry soil, and river stone) of any kind, making it convenient for on-site processing.

Speaking at the INTERMAT exhibition, Valerio Briganti, chief executive officer for MB France, North-east Italy-based MB Crusher has been selling around 1,000 of its high quality crushing and screening buckets annually over recent years. “Every year we increase our turnover around 10%, which is good,” he added.

As part of its growth strategy, MB Crusher last year enlarged its production facilities at its HQ to 17,000m². The ambitious firm has seven branches – in Italy, America, China, France, Germany, Japan, and India – with all its products manufactured in Italy.

As part of its commitment to innovation and its customer focused business philosophy, MB Crusher now allows customers to access via their mobile phones its B2B Portal - a login and password accessed software program including easy-to-follow video guides for optimising the performance of its impressive product range. The program’s other features include a spare parts ordering facility and a full product catalogue. Accessible via a mobile phone since last year, the B2B Portal has been available via MB Crusher’s company website since 2011.

After a successful 2014, in which the company’s products were sold in 39 countries, 24 of them outside Europe, Hartl Crusher presented its screening and crushing bucket complimenting HSCP 3300 screen plant at the INTERMAT 2015 exhibition.

The screening plant stands out with its extremely compact design and high screening efficiency; depending on the material, throughput can reach up to 90m³/hour.

“The main advantage lies in the screen box’s electro-hydraulic drive which provides more power than comparable pure electric drives and is also much more robust and durable. At the same time, with this drive system the speed of the screen’s rotation is continuously variable and a reversal of rotation direction is also possible.

The screen box is spring mounted and thus provides the best power transfer for both screen decks.

All components are high quality and are designed with component protection in mind”, says Georg Haberfellner, chief designer at Hartl Crusher.

This HSCP 3300 is used in natural stone processing as well as in the classification and refinement of recycled materials. The screener is also perfect for use in road construction and earthworks as well as forest road construction and excavations. When directly fed by a bucket crusher, Hartl Crusher says up to three categories of material can be produced, in combination with a bucket screener this can, says the company, be increased to four.

Furthermore, Hartl offers the appropriate electrically driven conveyor belts providing a maximum discharge height of 2.5m. The folding mechanism guarantees simple belt changing and reduces transport dimensions to a minimum.

The screening system, including conveyor belts, is said to have an electrical power consumption of only 14kW.

The benefits for the user are said by Hartl to be obvious: flexible, mobile and cost-effective separation of natural stones or recycled material on-site with minimum space and time requirements at the lowest cost.

A

Motem, based in Carpi, is the company working on-site in Fossoli. Its owner, Giovanni Stanco, rented the VSE40 from Modena Simex dealer Edil Ciesse. The screening bucket is getting rid of the soil from the bricks that make up the foundations of earthquake-damaged properties so that they can be used again in their renovation. Separating bricks and soil on-site is said to be significantly cheaper than transporting them for separation at a demolition centre.

With the VSE40, like Simex’s other VSE screening buckets, the user can switch from screening fine material of 15mm, then distance the drums to screen larger-sized material up to a maximum of 45mm. Output size adjustment is said by the Italian firm to be performed in only seconds directly from the operator’s seat via an electric control. The VSE40 screening bucket is said to increase productivity because it eliminates the downtime required for adjusting the position of the screening elements. This feature, in addition to making the attachment suitable for a wide range of operating scenarios, is said by Simex to significantly enhance profitability.