MIS Recycling A/S has started operating two new

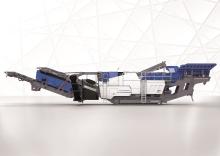

MIS is using Kleemann's latest MR 130 Zi EVO2 plants, which are equipped with the new SPECTIVE control system, are designed to be intuitive to use and can automate some machine functions.

The next few years are expected to see stricter regulations on the use of screening and crushing plants being implemented in the city centres of Copenhagen, Arhus and Odense. As it geared up for this development, MIS says it was important that its two new MR 130 Zi EVO2 plants met the exhaust emissions standard Tier 4 final. The Scania engine of the plant is fitted with a diesel particulate filter and a carbamide tank in order to reduce emissions of nitrogen oxides, carbon monoxides and fine dust. The company says this means that it is well equipped to meet the future requirements of the Danish recycling market.

MIS, which has been involved in the processing of residual construction materials for two decades, says the Danish recycling market has experienced a boom in recent years. The company processes approximately 3 million tonnes of residual construction materials and 100,000 tonnes of natural stone per year.

One of the most frequent applications is the processing of asphalt. The impact crushing plants crush RAP into grain sizes of 0–6mm and 0–20mm. The final product is returned to the asphalt production cycle. Occasionally bricks, concrete and track ballast are also processed. The crushing and screening plants are transported straight to the desired location, remaining on site for one to two weeks, depending on the size of the project.

To meet the demand for recycling in Denmark, MIS now operates 10 impact crushing plants from Kleemann’s MOBIREX series and three MOBISCREEN screening plants of types MS 12 Z, MS 15 Z and MS 16 D.

Kleemann GmbH is a company of the Wirtgen Group of international companies in the construction machinery industry. The Group includes the Wirtgen, Vögele, Hamm, Kleemann and Benninghoven brands, and is headquartered in Germany with local production sites in Brazil, India and China.