INTERMAT 2018, being staged in Paris (23-28 April), is the biggest construction and quarrying equipment exhibition in the world this year. The six-day showpiece offers plenty to interest the aggregates sector. Guy Woodford reports on some of the must-see models.

A robust and high-performance plant, the MOBICAT MC 120 Z PRO achieves an hourly output of up to 650 tonnes. The Continuous Feed System (CFS) is said by the German brand to guarantee the best possible crusher feed - regulating the material feed depending on the material flow. The model is very economical with its diesel-electric drive and can also be operated with an optional external power supply. To achieve effective prescreening of fines, the MOBICAT MC 120 Z PRO is equipped with an integrated double-deck prescreen with an extra-large screening area.

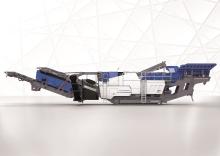

The plant in the EVO series are characterised by compact dimensions, good transportability and flexibility. This includes the new mobile screening plant of the MOBISCREEN EVO series. The exhibited double-deck classifying screen MS 952 EVO is suitable for natural stone and recycling applications in changing locations. The plant is very efficient and can process up to 500 tonnes of material an hour on a screening area of approx. 9.5m² in the upper deck. As with all EVO plants from Kleemann, all components are easily accessible for convenient maintenance. The screen media change in the lower deck, for example, is comparatively simple due to the lowerable fine grain discharge conveyor.

The mobile impact crusher MOBIREX MR 110 Z EVO2 is designed both for recycling and natural stone processing. The material is prescreened and levelled with the double-deck prescreen. Thanks to the well-thought-out material flow concept, the plant achieves an output of up to 350 tonnes an hour. The optional secondary screening unit has a very large screening area for a thoroughly classified final product. MOBIREX plant are equipped with the award-winning Lock & Turn system, which guarantees safe maintenance. Access to the plant is only possible via a multi-stage safety system and the rotor can be locked in any position to change the rotor ledges.

SPECTIVE is Kleemann’s new intuitively operated control system which will initially be available for PRO series crushing plants and the latest impact crusher in the MOBIREX MR EVO2 series. It uses clear symbols that make all plant functions identifiable at a glance. The 12-inch touch panel only displays information that is relevant to machine operation. The operator is guided through the control system in a similar manner to a smart phone, which considerably reduces the number of operating errors. In addition, data on machine operation can be called up in the plant cockpit.

Featuring a new and modern eye-catching design, both next generation R3e and R3 units are said to offer fast loading and short set-up times on site. They also feature a high level of mobility thanks to a supportless frame construction and rugged undercarriage track frame. Extensive coverings and wide-opening doors and flaps offer easy accessibility to all operational components and satisfy the requirements for operational reliability and maintainability. From the spring of 2018, the crusher will be available in its diesel hydraulic R3 form and as a fully-hybrid Keestrack R3e with a diesel-electric drive and full electric plug-in power supply.

At the heart of both versions is the high-performance impact crusher 48 ICR 100-00 with a large 770 x 960mm inlet opening, and claimed excellent crushing efficiency up to 250tonnes/hour via a heavy-duty 920mm rotor (diameter: 1100 mm, 3200 kg) and high rotor speeds. Specially adapted crushing tools, a wide adjustment range for both impact aprons (milling beam is optional) and a sophisticated overload system safeguard a broad range of applications from concrete recycling with intensive wear to the production of high-quality natural stone grains.

ALLU’s M Series Transformers for quarrying, aggregates and mining customers – three models for 50-160tonne excavators; and three for 30-100tonne wheeled loaders - are said to allow for the crushing and loading of raw material, such as soft limestone, to be completed in one cycle. The process change offered by the M Series model is said to reduce the need for buffer storage and extra material transport, with capital expenditure being lower than for large stationary processing stations.

For

With the CX750D excavator CASE wanted to keep close to the CX700 model in terms of ease of transportability, while having similar high levels of productivity and performance to a CX800 unit. The model has lower fuel consumption, a bigger pump and improved hydraulics compared to similar predecessor models.

Also on the quarry segment of its exhibition stand, CASE will display the CX300D 30-tonne crawler excavator, said to deliver best-in-class performance even in the tough conditions of quarries.

Show visitors can also discover how CASE’s award-winning G-Series wheeled loaders are proving extremely popular in global quarry operations.

Among

Having already been sold to quarrying and construction sector customers in Germany, France and Spain, SANY Europe believes the SY500 will remain in big demand due to its low fuel consumption and robust design. The OEM says it can be described as a “cost-effective workhorse”, with the further advantage of being easy to operate.

The machine features an EU Stage IV engine and ultra-low noise levels and further reinforces Komatsu’s move towards a sustainable reduction of the environmental impact of earthmoving machines. It is equipped with the same SAA6D114E‐6 engine 202kW as the PC360LC‐11, with up to 53kW extra electric power supplied by the revolutionary Komatsu Hybrid system.

Kinetic energy is generated during the swing-braking phase and is converted to electricity, which is sent through an inverter and captured by the Komatsu Ultra Capacitor. It is discharged for upper structure rotation when accelerating under workload conditions as well as assisting the engine as commanded by the hybrid controller. The reserve power stored by the hybrid technology represents additional horsepower that is available to maximise machine performance by supporting the engine, or is used for swing power.

From a haulers’ perspective, there will be much talk on the