German track-mounted mobile crushing and screening plant manufacturer Kleemann has ambitious global growth plans after a period of significant inward investment. Guy Woodford, editor of our sister title Aggregates Business, visited the company’s HQ to learn more.

Innovation, operator safety, simple handling and optimal performance are said by Kleemann to be the four key pillars on which the company designs and manufactures its plant range. Elements of all four can be seen in the MOBICONE MCO 9 S EVO plant I am looking at during my tour of Kleemann’s state-of-the-art manufacturing and assembly facility at the company’s HQ in Göppingen, a town around 30 minutes’ drive north-east of Stuttgart in south-west Germany.

Kleemann moved to its new HQ in 2009, three years after being acquired by the Wirtgen Group. A major site expansion project in 2016-17 increased plant assembly capacity by 50%, warehousing capacity by 100%, and created additional outside parts storage space. The same project included a big additional parking lot for the rapidly growing 500-plus HQ workforce. The whole HQ site now covers 150,000m² and includes the 45,000m² manufacturing and assembly facility (10,000m² of which is under a roofed area), and the 4,000m² office building. It has allowed the company’s development, construction and distribution capabilities to be housed efficiently under one roof.

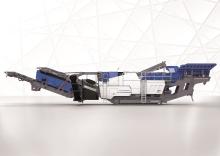

An entirely track-mounted mobile crushing and screening plant manufacturer since 2012, KIeemann’s current direct-drive range of diesel or diesel-electric powered models comprises seven 220-1,200tonnes/hour MOBICAT mobile jaw crushers, five 350-700tonnes/hour MOBIREX mobile impact crushers, two 300-400tonnes/hour MOBIFOX secondary impact crushers, six 270-650tonnes/hour MOBICONE mobile cone crushers, and 10 200-800tonnes/hour MOBISCREEN mobile screening machines.

All Kleemann crusher plant is manufactured, assembled, tested and quality-inspected at the company’s Göppingen HQ, while the company’s EVO screening plant are manufactured at Kleemann’s Pune, western India facility.

After my tour of the Kleemann production facility, I sat down with Dr Volker Nilles, Kleemann managing director, Mark Hezinger, Kleemann head of marketing, and Paul Holmes, managing director of Wirtgen Group UK & Ireland.

“We have spent some €50 million over the past three years on buildings and property, and this gives us growth possibilities for the long-term future” says Nilles. “The first big step was in the extension of warehousing and investment in increasing our model assembly capacity. It means for the next three to four years we are on course with our growth plan. Depending on how fast we progress, we have opportunities to add additional assembly, warehousing and office facilities. We also have an old hanger we are using for exhibitions, customer events, and facilities for sales and services training for customers, dealers and subsidiaries.”

Nilles says Kleemann has seen a clear trend in recent years of customers converting from stationary to mobile plant, not only in Europe but globally. As the company is now an entirely mobile plant manufacturer, this presents Kleemann with “exciting” growth opportunities.

Hezinger explains that although Kleemann now exists within the construction & forestry division of John Deere, the company has undergone no organisational change since John Deere acquired the €3 billion-plus annual turnover Wirtgen Group in December 2017. “Our business is a perfect fit within John Deere’s construction and forestry portfolio. Deere is very experienced in telematics and the use of augmented reality, and we can draw on that, and there are some synergies to be had around components, but other than that it is business as usual. That is very good for our customers and for us.”

At the bauma 2019 exhibition (8-14 April) in Munich, Germany, Kleemann appeared besides fellow Wirtgen Group companies Wirtgen (milling machines), Vögele (pavers), Hamm (compactors) and Benninghoven (asphalt plants), presenting a seven-mobile crushing and screening plant line-up. The models highlighted how the manufacturer’s design and engineering expertise are geared towards supplying customers with plant offering the best ‘stone-to-money’ ratio.

From the PRO series, the up to 650tonnes/hour capacity MOBICAT MC 120 Z PRO is said to impress in natural stone applications. The powerful plant has a 1,200mm x 800mm feed opening and is equipped with an extra long articulated crusher jaw. To guarantee the best possible material flow, Kleemann’s Continuous Feed System (CFS) adjusts the conveying speed to the crusher’s fill level. The model can rapidly clear material blockages by reversing production with the help of its electric crusher drive.

The bauma 2019-showcased MOBICONE MC0 11 PRO mobile cone crusher is a high-performing secondary crushing plant in combination with the MC 120 Z PRO. The MCO 11 PRO impresses with a maximum 470tonne hourly output.

Meanwhile, from the EVO series, Kleemann’s two packages for the MOBIREX MR 130 Z EVO2 impact crusher are said to guarantee environmentally sound operation. The newly developed solutions provide considerable improvements in noise reduction and dust containment. Operation of the plant is by means of Kleemann’s intuitive control concept, SPECTIVE.

The tried-and-tested MOBICAT MC 110 Z EVO jaw crusher and MOBICONE MCO 9 S EVO cone crusher are compact and powerful and can be combined perfectly. The MCO 9 S EVO also has a secondary screening unit with oversize grain returning.

The bauma 2019-highlighted triple-deck MOBISCREEN MS 953 EVO has a screening surface of 9.5m² in the upper deck. Just like the crushers, the screening plant in the EVO line can be used flexibly thanks to favourable transport dimensions and short set-up times. These advantages make them first choice for contract crushing companies and pure quarry applications.

The MOBISCREN MS 953 EVO’s up to 500tonnes/hour output is said to be possible thanks to a good material stream through the plant. This starts with the infeed which, thanks to the generously sized feed hopper, is supplied via a wheeled loader or an upstream crushing plant. The material is conveyed to the screen casing on an extra-wide 1,200mm feeding conveyor.

A coarse screening plant for larger feed sizes, the bauma 2019-displayed MOBISCREEN MS 15 Z is a mobile double-deck screen capable of an hourly output of up to 400tonnes. Well suited to both natural rock and recycling applications, the robustly built screening plant can process up to 400mm-sized initial feed material.

Focusing on the evolution of Kleemann’s plant range, Nilles says: “After 2010 we developed the EVO line of jaw, cone, impactor and screen plant aimed at the contractor market. We are not trying to develop only a product, but also a total solution for our customer.

“We differentiate our EVO lines from other manufacturers through their performance. They offer higher tonnes per hour with technological features such as our CFS system and material flow concept. This lowers total cost of ownership for our customers. The EVO range is also all about efficiency. The main topic within that is offering lower fuel consumption than our competitors, which we do with our direct-drive concept and our diesel-electric powered option.

“Finally, we focus on design. We think we have very nice machines and we’ve won a lot of design prizes. But for us the design is not only about the plant looking nice, but about being easy to operate and maintain. If you look at our plant you can find the SPECTIVE operating system which can more or less guide you through the whole plant operation process, while also offering solutions to fix any problems. We also think we have the safest machines on the market and have won a couple of safety prizes with our EVO machines.”

Kleemann trades through its 55 subsidiaries and 100 dealers globally. In North America the company sells its products through dealership partners, with its trading in China managed by its subsidiary overseeing a dealer partner network.

“The subsidiary approach is quite different to our competitors and gives us direct access to most markets globally,” explains Nilles. “Our position in Europe and South America is stronger than in some other areas, and we are also market leader [for track-mounted mobile plant sales] in China. Nevertheless, everywhere has growth potential for us. Our target is one third sales in Europe, one third in North and South America, and one third of sales from the rest of the world.”

Of Kleemann’s home market of Germany, Nilles says: “The German equipment market is still very strong. We have a number one position here and are still growing.”

Nilles stresses how Kleemann has been continuously updating its products and “taking them to the next level”. This will include, he says, the launch of additional all-electric Kleemann electric crushers and screeners “within the near future”.

“We are also continuously increasing our plant portfolio. We did this initially within the EVO line and then introduced the PRO line, which are especially for the quarrying and mining business. Those crushers are very robust but remain quite mobile. The MCO 11 PRO and MC 120 Z PRO have been introduced to the market, and there are more to come.”

As well as having recently showcased its SPECTIVE machine control solution and the MOBICAT MC 120 Z PRO jaw crusher for the first time at the bauma Munich exhibition, Nilles says Kleemann was also keen to highlight the MOBIREX MR 130 Z EVO2 impact crusher’s new features for reducing plant dust and noise levels, which he describes as “a very critical issue in a lot of countries”.

Emphasising Kleemann’s consistent approach to brand quality, Paul Holmes says: “If you walk round the Indian factory where we produce our EVO screening plant, you would find no difference from our factory here in Germany – from a quality perspective, an engineering perspective, and a control perspective. That’s the Kleemann brand.”

Nilles says there are plans for Kleemann’s scalpers to be manufactured in India. “There are cost advantages to manufacturing there. For example, the percentage of steel cost in producing a screener is much higher than in producing a crusher. Also, a one-production facility strategy is very risky in the long term.

“There are markets we are closely following, such as China, which is the largest aggregates market in the world. So far it remains a mainly stationary plant market. If it gets to the stage that mobile plant becomes more established, we will have discussions about a Chinese production presence.”

“With our Indian factory, we have a proven overseas production facility. This stands us in good stead for other potential overseas production sites,” adds Holmes.

Nilles notes that annual Chinese crusher demand is around 15,000 units/year – with around 95% of those being stationary plant purchases. He adds: “There’s a lot going on in China. New government environment legislation and market consolidation is leading to the closure of a lot of small quarries. There are new projects on both the recycling and aggregates quarrying side of the business. This has opened up discussions about the benefits of mobile plant for these projects, creating good potential for both our EVO and PRO plant lines.”

On this topic, Holmes adds: “It’s not just about introducing more mobile plant to China, it’s about having the capability of supporting customers’ use of the plant.”

Kleemann has invested heavily in its subsidiaries’ regional sales and services outlets. Centre for Training & Technology (CTT) teams offer expert maintenance and repair of customer plant, preventative maintenance through service contracts, and application advice and training.

“We want to deliver a solution that allows our customer to earn money by lowering their cost per [production] tonne. Lowering this cost involves quality plan maintenance and operation that ensures high plant availability. We offer application engineering support to achieve this. You can buy a machine, but if you do not set up properly you cannot achieve best results.

“We offer everything from standard to full-service and maintenance contracts, depending on regions. For example, we have a lot of full-maintenance contracts in India. It is part of the business we are developing with our subsidiaries, with contracts tailored to market specifics.”

Focusing on Kleemann’s customer plant replacement parts business, Holmes says: “The crushing and screening plant market has traditionally included a lot of third parties working out of forges all over the world who are producing replacement parts of varying quality and price. A lot of other crushing and screening equipment manufacturers have been happy to let these localised third-party suppliers supply their customers with replacement parts. We say an OEM- (original equipment manufacturer) produced part does not mean expensive; it means value.

“For the UK market, certainly, we’ve been very conscious to ensure we’re price-competitive against third parties, that we match or exceed quality, ensuring longer wear life, and importantly that we have the availability of the ordered replacement part. This prevents downtime which costs money. I think we have been helped in this area by John Deere, and their agricultural side, in upping replacement parts availability. This means upping warehouse space, like we have done in the UK, so we can supply the customer immediately or next day with at least 90% of what they need, to get them back up and running.”

‘Up and running’ is also a good way to describe Kleemann’s global growth plan. It will be fascinating to witness its full delivery over the coming years.