At a quarry in Italy, MB Crusher claims to have provided a method of fully exploiting waste and turning it into a resource that produces wealth and value. Material that had been excavated to start the cultivation of a new area of the quarry was being left aside, effectively as waste.

To address this, the Italy-based equipment company has attached one of its MB-S23 screening buckets to a Hitachi Zaxis 460 LCH excavator at the quarry site in Lazio.

The bucket divided the material into two parts. Fines material from 0mm to 100mm was sold for the construction of embankments. The remaining rocky aggregates over 100mm left inside the screener basket were tipped out directly into a dumper and added into the processing cycle to be transformed into granulates for the building industry.

This simple separation solved an open-ended costly issue, according to MB Crusher. The presence of clay and soil fractions made the material complicated to crush and therefore it was impossible to market, but by simply separating and cleaning the material it became suitable for sale and reuse.

MB says that the use of its screener bucket units has transformed the material into a “co-product” in a simple way, both from a technical and economic point of view, without risks for the environment.

“Given the simplicity of the operations, moreover, this intervention had a great economic benefit for the company that owns the quarry,” MB Crusher states. “No more storing the excavated material means full exploitation of the resources and also means fewer safety problems for those operating in the quarry.

“The systematic recovery of quarry tailings, together with a rational approach to the cultivation of the quarry itself, goes from problem to solution, from waste to a source of income.”

Finnish company Metso says that it has helped boost productivity at the Creuzeval quarry in Saint-Didier-sur-Beaujeu, France, by utilising its SiteBooster plant optimisation solution to modernise its ageing crushing plant.

The old plant had been operated by the CBR company for four decades at the quarry in the heart of the Beaujolais Geopark. The modest-sized 17-hectare quarry had an annual production of 250,000 to 300,000 tonnes of aggregates that supplied nearby asphalt plants.

Metso says that the stationary old plant – and more precisely the primary stage - was starting to lose productivity due to repeated stops to adjust settings and perform other maintenance operations. Nicolas Vignon, site manager at CBR, decided to use the SiteBooster solution to modernise the Creuzeval plant.

The maintenance cost of the existing scalper was around €20,000 to €25,000 per year. After an initial audit performed by Sébastien Thévenet, project manager of the SiteBooster team, it appeared that the jaw crusher was also starting to show signs of age.

Based on a budget of about €500,000, the SiteBooster proposal was accepted by the customer. The scalper, a Metso EDB 15-39, has been replaced with a new scalper of the same model “to avoid changing the frame,” and the jaw crusher, an old VB 1311, was retired and replaced with a new Nordberg C Series C130 jaw crusher, bringing improved maintenance access all around the crusher.

The project started with a preliminary phase, auditing the plant to identify bottlenecks and taking accurate measurements. Jean-Yves Cognard, operations and services director at Metso, says this is necessary as dimensions are standard for the machine, but not for plant.

After this preparatory phase, three months were allocated to the plant redesign and the manufacturing of the two requested machines and ancillary parts. Then, all on-site operations, the dismantling of old equipment, the assembly and start-up of new equipment, took about a month. It was imperative to respect the short deadlines imposed by the customer, whose operations were not reduced during summer, as he had to continuously supply his products to multiple asphalt plants. In anticipation of the one-month plant shutdown, quarry manager Alexis Humbert had to store 50,000 tonnes of primary crushing products before revamping operations.

Commenting on the outcome Nicolas Vignon said: “The big advantage is that the new system is easier to use and more reliable. The primary crushing plant sees less downtime. When you have to tighten the jaws, now it takes five minutes using the hydraulic system, compared to the two hours previously.”

Terex MPS launched its latest crushing and screening solution, the Cedarapids CRH1113R closed circuit impactor crusher/screen plant.

The CRH1113R portable plant – launched under Terex’s Cedarapids brand – features a brand new crusher, screen, and feeder that are designed to maximise the production of the machine.

Designed as a one-piece tow, the portable crushing and screening solution is designed to be easy to transport on highways or to move onsite. Hydraulics on the screen and return conveyor are intended to give quick, easy, and safe set-up.

The machine is self-contained with on-board diesel power and generator. The 450hp variable speed Scania diesel engine direct drives both the crusher and 150kW generator with a hydraulic clutch. The rest of the plant is electrically powered and designed for maximum efficiency and minimal maintenance.

The plant features a TI4250 crusher which has hydraulic-controlled curtains to make adjustments and maintenance safe and quick. The variable speed diesel allows optimum rotor speed to best match the application and desired product. The 6’x16’ (15.24cm x 40.64cm) two-deck screen dual-slope design features a steeper top deck to handle heavy loads and quickly stratify material.

The lower deck has less slope to increase retention time for maximum screening efficiency. The entire screen can be positioned with more or less slope to optimise production. The new vibrating grizzly feeder is 48” wide x 18” long (121.92cm x 45.72cm) to handle feed from large loaders.

Terex MPS product manager Ed Sauser said: “The CRH1113R is the result of customer input and recognising the need for a highly portable plant that offers higher production and greater value than what’s on the market today. The brand new crusher, large screen & feeder, and low-maintenance electrically driven components make this one-piece towable machine great value for processing shot rock as well as concrete and asphalt recycle materials.”

Kleemann showcased four of its latest products at the March ConExpo event in Las Vegas, including three crushers and a screener.

The MC 120 Zi PRO jaw crusher is made for challenging natural rock quarrying operations. The plant has an output of up to 650tonnes/hour, features a powerful jaw crusher with a feed opening of 1.2m x 81cm (48” x 32”), and is equipped with an extra-long articulated crusher jaw.

To ensure the best possible material flow, the continuous feed system (CFS) adapts the conveying speed to the fill level of the crusher.

Should material bridging occur in the jaw crusher, the crusher can be reversed with the aid of the electric crusher drive to swiftly clear the blockage. The machines of the PRO line can be operated with the simple SPECTIVE control system via a 30cm (12”) touch panel, and all components and functions can be controlled from the ground.

Also on display at ConExpo was the mobile MOBICONE MCO 11i PRO cone crusher, which Kleemann says is the perfect secondary crushing screen of the MC 120 Zi PRO. The MCO 11i PRO has a maximum output of 470tonnes/hour. Also part of the PRO line, the crusher is designed for permanent quarrying operation.

The MOBIREX MR 130 Zi EVO2 impact crusher is designed for flexible use so that it can be transported easily and rapidly made ready for operation. The direct diesel drive concept is designed to ensure a high output while simultaneously keeping consumption low. For better capacity utilisation and productivity, the system widths of the impact crusher plant open in the direction of material flow. The plant is also operated using the intuitive SPECTIVE control concept. The overall system itself has an output of up to 450tonnes/hour.

Kleemann says the MOBISCREEN MS 952i EVO classifying screen is an ideal support unit for all three crushing systems and is suited for crushing plant contractors in both recycling and quarrying. The MS 952i EVO has a screening surface of 1.55m x 6m (5’ 1” x 20’) and has an output of up to 499tonnes/hour.

The high output is largely attributable to the good material flow through the plant, according to Kleemann. This starts with loading, which can be carried out both by wheeled loader and upstream crushing plant due to the generous feed hopper. The material is then transported on the extra wide feeding conveyor of 1.2m (3’ 11”) to the screen casing.

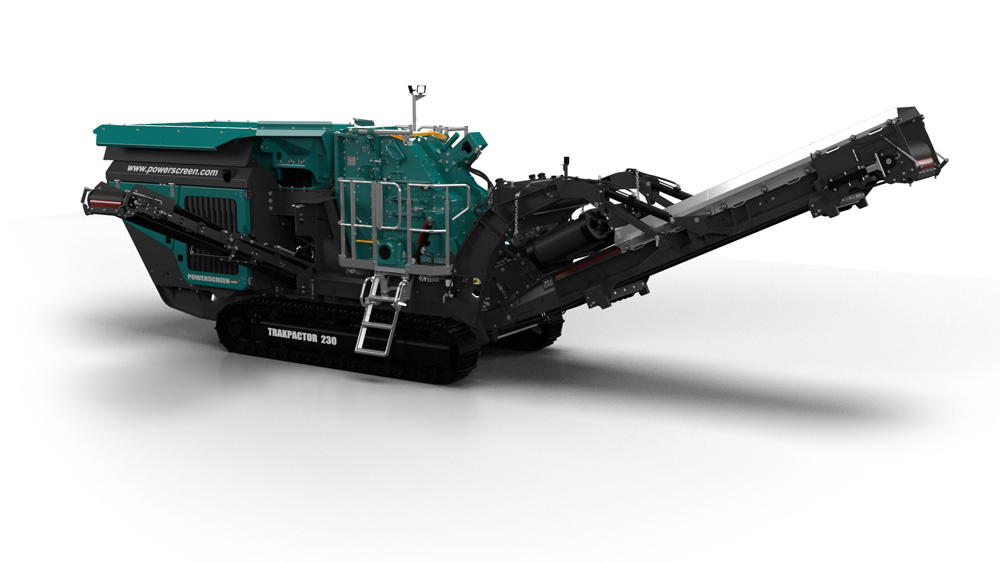

Powerscreen has launched the new Trakpactor 230 and 230SR impact crushers.

The Northern Irish mobile crushing and screening equipment manufacturer says the Trakpactor 230 and 230SR have been designed to offer both excellent reduction and high consistency of product yield. The machines can be utilised in a range of applications including aggregates, recycling and mining.

The Trakpactor 230SR includes a post-screen system and recirculating conveyor which allows oversize material to be passed back to the crusher for further sizing.

Powerscreen product manager Neil Robinson said: “The new Trakpactor 230 and 230SR are very welcome additions to our mobile impact crushing range and are the first of many exciting new product development initiatives for Powerscreen this year. Addressing feedback from Powerscreen dealers and customers, both machines are suited to small to mid-sized operations that require a reduced footprint without compromising on output performance.”

He added that the Trakpactor 230SR has the ability to convert to the Trakpactor 230 in minutes thanks to the quick-detach SR section, making it a suitable solution for regions with transport weight restrictions. Robinson said the units have been designed to promote optimal flow of material and offer excellent serviceability to maximise uptime for customers.

The Trakpactor 230 & 230SR crushers both use an 860mm x 720mm impact camber with an output potential of up to 250 tonnes per hour (275 US tph) of crushed material.

The two new crushers come complete with the Powerscreen Pulse remote-monitoring, fleet management system allowing crushing and screening equipment operators and owners to have access to key data via a PC, tablet or smartphone. The system provides information on the GPS location, start and stop times, fuel consumption, tonnages, cone settings, wear ratings, operating hours, maintenance status, and other data.

R Collard’s new fixed crushing line became operational in March. The state-of-the-art plant will allow the Hampshire, south-east England-based company to produce 250 tonnes of high-grade recycled aggregates an hour, increasing its current capacity by over 200%.

With an investment of £2 million, the plant manufactured by Duo is bespoke to R Collard, built to the firm’s own specification and design.

The size of aggregates that will be produced by the new plant include -5mm, +5-20mm, +10-20mm, +20mm, and +40mm.

The new plant will not only allow R Collard to increase its production of recycled aggregates already produced by the company’s wash plant. It will also feed its concrete plant in the production of its ready-mix concrete