Independent family-run business North Lincs Aggregates, which owns and operates three quarries, has invested in more

Located in Northern England, the company’s Finningley operation has been established for around 12 months and already runs a

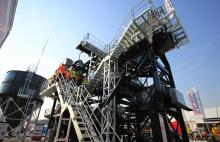

Operating independently at 160tonnes/hur, this mid-size mobile plant complete with on-board hydraulically folding side conveyors for up to five-way splitting of material, produces a 0–4mm grit sand; 20mm and 10mm aggregates, and oversize, which are sold to local concrete plants.

Originally supplied by DUO (Europe) for use at North Lincs Aggregates’ quarry at Cove, the plant was subsequently moved to nearby Finningley, where it has had to cope with an increasing amount of oversize.

As a result, a decision was made to invest in a Powerscreen 1000

“We have a long-standing relationship with DUO, who supplied the M1700 and other equipment for our various operations, so it made sense to buy a 1000 Maxtrak cone to crush the oversize and a Warrior to dry screen the sand,” says Richard Mills, managing director of North Lincs Aggregates.

The quarry at Finningley, which has reserves of approximately 3.5–4 million tonnes of quartz gravel and sand, had lain dormant until bought by North Lincs Aggregates 12 months ago.

“We are a self-funding company so purchasing Powerscreen equipment from a trusted supplier like DUO makes sense. We purchased the equipment outright as the brand retains a good residual value, ideal for when we need to upgrade again,” says Mills.

The processing operation at Finningley is relatively simple. Sand and gravel dug from the quarry is sent to the MWS M1700 wash plant while the oversize is stockpiled for delivery by wheeled loader to the 1000 Maxtrak cone crusher, which operates at 100tonnes/hour.

The oversize material is reduced down to 20mm, plus an associated dust, which is subsequently re-fed through the wash plant along with the raw feed material.

The duty of the Warrior 1400X is to dry-screen sand and gravel using a 4mm piano wire mesh to provide a dry building sand.

“Both machines have been delivered within the last three months,’ says Mills.

“Overall we are very happy with the machines supplied by DUO and have every confidence in the reliability of the equipment, and the service back-up.”

Nico Stroh, development manager at DUO, says: ‘The machines supplied to North Lincs Aggregates are perfect for its operation and offer reliability and efficient processing. We are very confident in our supply of the full range of Powerscreen equipment, which blends perfectly with the TWS range of washing equipment.”