Demand increases for quarry’s sand and gravel products following the installation of a wet processing system. Liam McLoughlin reports.

Located in the French countryside of Brinon-sur-Sauldre, close to Orleans, the Sablière du Val de Loire quarry is preparing to double its production from 60,000 to 120,000 tonnes annually.

The alluvial material is made up of 50% sand and 50% gravel and treated using a bespoke CDE solution, consisting of a wet processing unit and a water recycling unit. Very low in clay, the excavated material is dry and is fed directly into the hopper.

The quarry produces 60,000 tonnes of sand and gravel (4/10, 10/20, 20/40). Sixty per cent of the output is destined for the concrete industry and 40% for the civil engineering market. Rodolphe Gabriel, the owner of the quarry, says that the company also produces “sand graded 0/4 and below. This product is very fine, resembling beach sand. It’s popular with the region’s builders and plasterers because it can be worked into a very smooth product.”

The quarry serves an area covering French departments 18, 41 and 45 within a radius of 30 kilometres around Brinon-sur-Sauldre. CDE says this allows it to remain competitive in the raw materials market thanks to strict management of transportation costs and to pay close attention to its environmental impact.

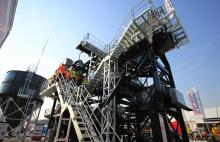

CDE’s M2500 E4X wet processing solution was co-developed with Rodolphe Gabriel to precisely meet his production requirements. The installation incorporates a feeding system, a sand treatment unit with cyclone technology, a washing and classification unit and stockpile conveyors on a single chassis. It is also linked to a waste water treatment unit – a CDE AquaCycle thickener with a capacity of 400m³/h, which allows up to 90% of the used water to be recycled for immediate re-use in the system.

The CDE M2500 E4X includes a wet processing unit based on a CDE washing screen, a jet pump and a double-pass cyclonic unit for optimal washing. Marc Sopransi, business development manager for CDE France, says: “The jet pump is a substantial technological benefit. A high-pressure jet is located at the base of the washing screen sheet which collects the 4/10mm fraction. The material is then pumped and transported by a pipe to the dewatering screen at the front of the unit. This creates slightly increased additional attrition and provides an even higher quality product.

“Here, the jet pump treatment is applied to the 4/10. The granulometry curve of the Sablière du Val de Loire project lends itself to the use of this technology.”

Using this unit, it is possible to draw four fractions from the alluvial material. The washed products have a level of humidity of around 12% when they exit the conveyor belt, making them ready for immediate sale to the region’s construction and building companies.

Gabriel adds: “As well as being effective and reliable, the CDE equipment is also easy to use. A single operator is enough for the plant to produce 60-100 tonnes per hour. Given that the quarry is isolated, we of course prefer, for safety reasons, to always have two employees working together.”

The wet classification screen incorporated into the CDE equipment at the Sablière du Val de Loire quarry is able to produce four fractions simultaneously, on two decks.

The specific arrangement of the bottom deck of the screen allows for the classification of an extra product, totalling three. The 0/4mm fraction passes through the upper part of the bottom deck before it is pumped to the cyclone. Meanwhile, the 4/10 passes through the lower part of the bottom deck and falls into its own sump, at the end of which the jet pump is located. Finally, the 10/20 fraction rolls out of the bottom deck of the screen to be stockpiled.

The system also includes a waste water treatment unit – a CDE AquaCycle thickener with a capacity of 400m³/h – which allows up to 90% of the water used to be recycled via a system that traps fine materials and expels sludge into two settling ponds.

Rodolphe Gabriel explains: “The quarry doesn’t waste anything. We are very committed to protecting the environment and have put in place systems to preserve biodiversity.

“The use of a CDE AquaCycle contributes towards this effort. After an initial fill of 350m³ of water, 90% of the used water is recycled and reused in the system. We even recycle the water captured in the neighbouring ponds and ditches. 30 to 40m³/h of water is enough to keep the system going.”

Sopransi continues: “The process water, after passing into the deaeration chamber and having the flocculant added, passes gently to the centre of the thickener so that the flocculant can work and act on the sedimentation of the fine material.

“The system’s integrated flocculant station allows precise dosing of the pre-mixed flocculant for efficient settlement. A single motor operates the rack arms of the AquaCycle for optimal treatment of the sludge prior to its drainage.

“The conical section of the thickener, with an integrated sludge pump, allows for rapid installation and start-up.”

CDE states that strategic management of its resources and its operating priorities means the Sablière du Val de Loire quarry has until now been able to easily meet the demand for 60 tonnes an hour of washed, ready-for-sale sand and gravel. Today, this demand has increased significantly and Gabriel expects to double his production within the coming months. He says: “The industry of quality washed sand and aggregates is highly competitive in France and our CDE system has allowed us to rise to the challenge of meeting demand to position the Sablière du Val de Loire quarry as a growing player in the market.

“Our aim of doubling our current production means a rapid return on investment, thanks to the equipment which is highly performant, economical, reliable and easy to operate by a minimum of employees.”

More than 100 dealers and customers have attended the first-ever

The forum ran from 24-27 September in Connecticut, USA and included a conference, site visit and Dealer Awards Ceremony. Terex TWS says the event provided a focused opportunity to engage with customers and showcase its latest innovations.

The highlight was the first-ever exhibit of TWS’ complete end-to-end washing solution, consisting of an AggreSand 206, a FinesMaster C Type Classifier and a full TWS AquaClear Water Management System. The solution is designed to offer a unique one-stop solution for washing and water management from a single supplier.

Attendees enjoyed a full-day conference where they learned about the various applications served by TWS products (aggregates, recycling, mining, industrial sands, and water treatment), as well as latest product advancements, innovations and future plans. They also took part in a site visit, incorporating a machine demo and tour of the end-to-end washing solution.

The Global Dealer Forum closed with an awards ceremony during which the top performing dealers across the world were celebrated during a gala dinner. TWS recognised five dealers through Special Recognition Awards – Duo UK,

Oliver Donnelly, director Terex Washing Systems, said: “Our Global Dealer Forum was an important event to engage with our dealers and customers and to celebrate our mutual success through the Dealer Awards Ceremony. It also provided an invaluable opportunity for us to exhibit and demonstrate our AquaClear range of water management products which now form a core part of our offering.”

McCloskey Washing Systems (MWS) held its first North American Open Day at H&H Stone in Bolingbrook, Illinois, from 20-21 June this year. The event highlighted new washing and classifying equipment for both quarrying and recycling applications.

H&H Stone was established in 2013 when owner Dave Hamman and a partner purchased the limestone quarry in Bolingbrook and a sand and gravel pit in Boone County, Illinois. They took delivery of the first Sandstorm 620 wash plant in the USA following its debut at Conexpo-Con/Agg 2017 in Las Vegas.

MWS hosted a live working demonstration of the Sandstorm 620, producing 0-2mm and 0-5mm grades of sand while producing more than 40mm of rinsed stone.

The product from the Bolingbrook plant is sold to ready-mix companies and precast companies. The ready-mix companies use it for foundations in homes and driveways while the precast companies use it to manufacture precast panels for distribution building and concrete precast buildings. The sand plant also has the capability to blend all or some of the fine sand into the coarse sand to maximise the required grading.

Sean Loughran, director MWS, commented: “The initial interest in the open day was phenomenal, and we quickly realised that we were going to have to spread the event over two days to accommodate all those who wanted to attend.”

As the first wash plant from MWS in the USA, the Sandstorm’s installation was managed and closely monitored by US Equipment, the MWS dealer for the state of Illinois. US Equipment is a provider of material processing & handling equipment in the area, specialising in the construction and aggregates industries.

Simon Bradley, owner of US Equipment, added: “H&H Stone’s Sandstorm 620 received lots of positive feedback, with visitors impressed by its innovative compact size, while providing maximum access to serviceable areas and producing high-quality product.”

MWS says the two-day event saw a strong turnout of dealers and customers from across North America. Throughout the open day, a team of McCloskey engineers, sales and applications managers were on hand to give guided machine tours and application discussions. Attendees had the opportunity to inspect the machines after the demonstrations and learn more about the features and benefits.

The company designs and manufactures a full range of modular, mobile and static washing equipment for the aggregates, waste & recycling, mining and construction & demolition (C&D) sectors.

A division of

US-based

McLanahan says UltraWash plant are ideal for producers facing criteria such as planning permits, multiple locations, short-term deployment, or an unknown/variable feed stock (e.g. C&D waste streams applications) that make implementing a customised processing solution difficult.

“That is where smaller footprint, skid-mounted modular plant such as the McLanahan UltraWash come in,” the company states. “The UltraWash allows operators earlier permitting and fast set-up, resulting in earlier returns on investment. These modular wash plant come in preassembled modules that are pre-wired and pre-plumbed for rapid on-site deployment. They feature a fully integrated control system with remote operation.”

Currently available in three sizes, the UltraWash can produce up to three aggregate products and up to two sand products. There is a single process water feed point, as well as a single effluent discharge point.

McLanahan currently offers several additional configurations and add-ons to the UltraWash, including: single or dual sand product; feed preparation (log washer, blade mill, coarse material screw); attritioning module for specialty sand production; organics removal module; water treatment with high-density or paste-style thickener; and filter press for complete wastewater treatment.