BPE Lecieux, a stone and gravel company located in Saint-Maximin, in the department of Oise, northern France, is using a custom-made

Headquartered around an hour’s drive north of Paris, BPE Lecieux exploits the deposits of three limestone quarries: the Verbois site, the Ouachée and Corpechot quarry at the Les Dormants site, and, since recently, the former

Established in 1957, BPE Lecieux has become a reference of excellence in the construction and public works industry. The quality of its materials, whose uses include the restoration of the Château of Versailles, the Louvre and the Panthéon, as well as many other historical monuments, is the result of years of innovation and technical improvements in the processing of the stones found in the Paris Basin. BPE Lecieux owns 300 hectares of quarries of Lutetian limestone, a creamy light beige stone typical of Paris’ most famous buildings, and works in full accordance with the Environmental Charter of the Quarrying Industries to preserve the Oise-Pays de France regional natural park.

Until 2014, BPE Lecieux had used a washing system to treat alluvial sand deposits. However, after the acquisition of Lutetian limestone sites, the company had to adapt its technological requirements to the production of new products corresponding to the standard specifications for ready-mixed concrete. The site of the treatment platform in Saintes Barbes presented the ideal conditions for the installation of a washing system specially developed for the production of materials to meet ready-mixed concrete standards while protecting the natural environment.

The raw material obtained from a combination of materials is essentially soft limestone with a particle size of 0-20mm or 0-40mm, processed by a custom-made CDE solution comprising a wet processing unit combined with a waste water recycling unit. The Saintes Barbes site produces between 80 and 100 tonnes per hour of materials for the concrete industry and public works market. Three products are processed simultaneously by the CDE system: 0-4mm, 4-10mm and 10-20mm.

The gravels graded 4/10 (known as mignonette gravel) and 10/20 are used to produce concrete and products for landscaping projects. The quarry material also allows the production of a dry sand with a grain size of 0-4mm, which is highly polyvalent and especially well-suited to masonry as well as some construction and public works applications requiring sand which is fine and easy to work with.

Jean-Luc Roussel, sales manager for BPE Lecieux, and Dominique Lecieux, the company’s extraction manager, add: “BPE Lecieux’s Saintes Barbes site is ideally located a few kilometres away from our Parisian markets, which allows us to remain competitive in terms of the price of the materials thanks to strict management of transportation costs and close attention to the environmental impact of our operations.

“We feel lucky to have the opportunity to process a type of limestone that is imbued with history, the Lutetian limestone; it is typical of the Paris Basin and grants the buildings of the French capital their unique soft blond shade. For all our clients, including those involved in the restoration of listed buildings, we adhere to the most rigorous quality standards.”

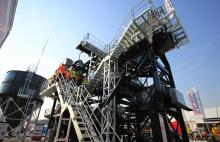

The CDE M2500 E3X wet processing solution, co-developed with BPE Lecieux in order to meet its production needs, integrates a feeding system, a cyclonic sand treatment unit, a sand and gravel washing and classification system and stockpile conveyors on a single chassis. It is combined with a waste water treatment unit - an AquaCycle A600 CDE thickener with a capacity of 600m³/h - which allows up to 90% of the used water to be recycled for immediate re-use into the system. The tailor-made feeding system has been completely modernised and increased in terms of throughput, while fully adhering to the required plan.

CDE’s M2500 E3X includes a wet processing unit which consists of a washing screen, a cyclone and a drier. Marc Sopransi, business development manager for CDE France, explains: “The M2500 E3X demonstrates the efficiency of CDE’s cyclonic technology and the adaptive ability of our process and engineering teams, who designed a bespoke process to the needs of BPE Lecieux in order to extract from the sand the smallest possible amount of fine material, which is highly appreciated by the company’s customers.

“The hydrocyclones were built in accordance with the client’s specific needs, on the basis of the analyses of the feed product carried out directly by the CDE laboratory during the preliminary phase of the project.

“The used water carrying unwanted particles is expelled from the cyclone overflows, while the washed sand, having been processed, continues on to enter into the drying and storage stages. Thanks to cut points of unrivalled precision, the three products are processed simultaneously to the required standards and without any risk of cross contamination amongst the products.”

The Saintes Barbes quarry plant also includes a waste water treatment unit - a CDE AquaCycle A600 with a capacity of 600m³/h - which allows up to 90% of the used water to be recycled using a system dedicated to the removal of fine particles via flocculation and expulsion of sediments, formed by precipitation, into a settlement tank. Extra water is added to the treated water via a CDE Aquastore AS556 unit. This very limited amount of extra water serves to compensate the losses incurred due to residual moisture in the sand and sediments. The water is then sent immediately back towards the process, which thus functions almost as a closed system.

“The integrated flocculation station allows for precise dosing of the pre-mixed flocculant for efficient settlement. A single motor operates the rack arms of the AquaCycle for optimal treatment of the sediment prior to drainage.”

CDE’s machines are designed and constructed at the company’s facilities to adapt to the needs of each application, in order to maximise the quality and quantity of the materials produced. In the case of the Saintes Barbes site, processing of the rare type of limestone requires a high level of precision.

Around 90% of the material available - a soft limestone which is sensitive to the penetration of moisture - is made use of. The raw material therefore poses the risk of coagulating into a thick paste. To ensure fluid and constant feeding, it was essential to factor in key factors including the angles of the slopes and the size of the conveyors. The CDE team, in collaboration with the client, designed a tailor-made solution with a minimum of steep angles and with slopes calculated to avoid any risk of blockage. The management of BPE Lecieux says: “The design of our CDE system has proven itself over the past three years. The crushed raw limestone contains 28% of fine particles, which needs to fall to 12% to meet ready-mixed concrete standards.

“We pursue a goal of “zero waste” and the CDE machinery offers a range of high-tech products which allows us to achieve this. The modular nature of the equipment allows us to consider and visualise future improvements which integrate perfectly into the existing system.”

Each CDE materials processing project benefits from the company’s own “customer for life” methodology. This provides regular and consistent service, with a minimum of intermediaries, preferring a single point of contact to ensure clear and efficient communication from the start of the planning process through to the end of the plant’s lifespan.

Jean-Luc Roussel concludes: “We are happy with the quality - price ratio of our machinery and especially appreciate CDE’s after-sales service, with its team in France being always on call.”