The German-headquartered manufacturer adds that the focus at Booth 149 in Hall B2 will be on robust plants, precise systems and clever processes for the preparation, analysis and processing of building materials.

The Haver & Boecker Machinery Division will be demonstrating how elaborately manufactured, valuable powder product can be securely protected and completely

used by the end customer - packed in a tightly closed, tear-resistant and clean film packaging.

The packing specialist will present a closed recycling circle for these completely residue-empty film bags based on a concrete case study.

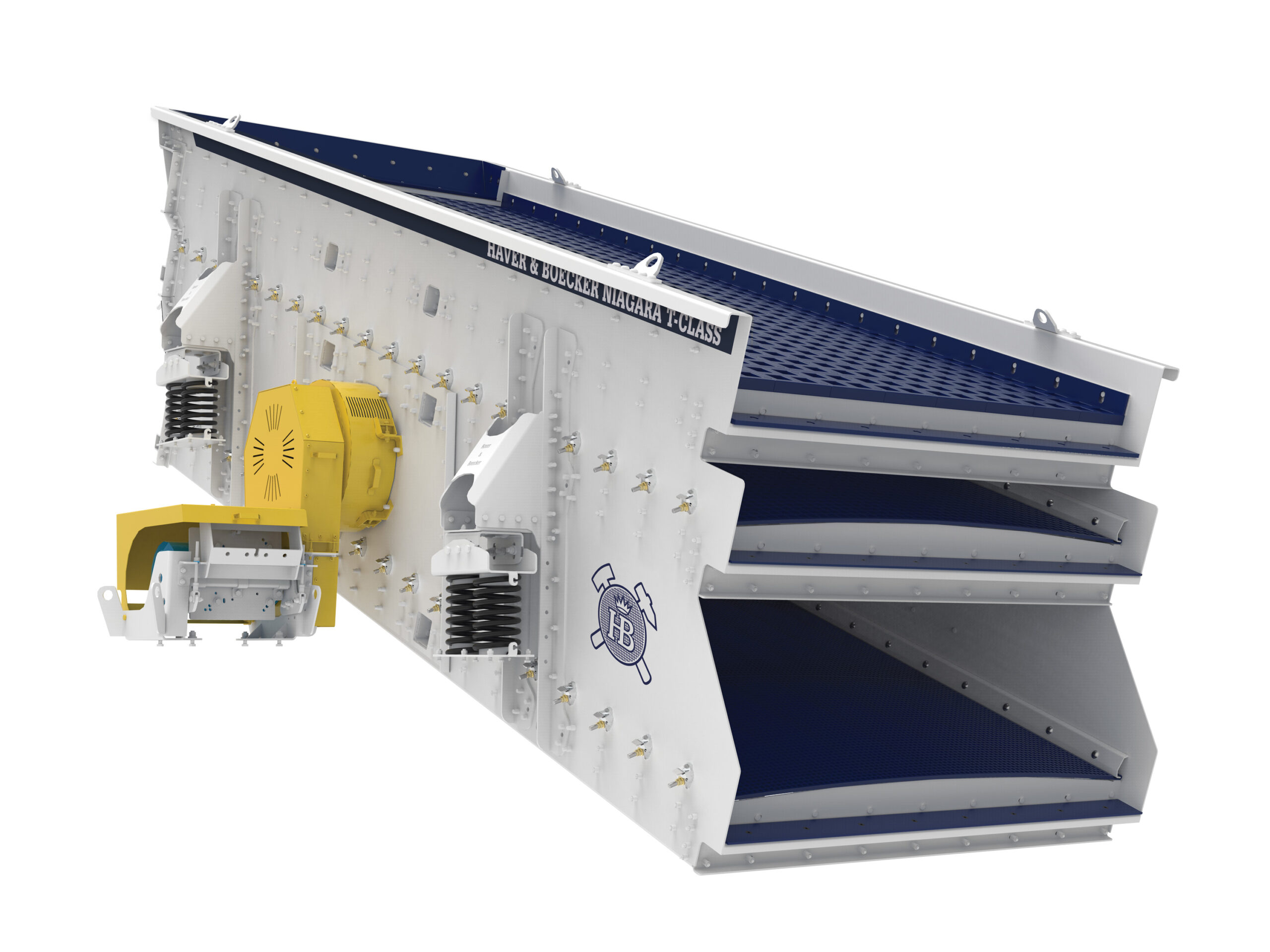

Haver & Boecker Niagara is presenting the new generation of the Niagara T-Class free swinging screening machine live at bauma. The focus will be on all details of a cost-efficient and maintenance-friendly solution for the safe processing of building materials and challenging materials from the mining industry. Visitors will learn how to take digital monitoring of their vibrating screens to a new level with the Pulse Condition Monitoring (Pulse CM).

The Major Fit wire mesh will be in the focus of Major Europe's exhibition appearance. These are square mesh available from stock with high-strength spring steel wires in Stelmore quality, along with square and rectangular mesh in various materials. Screens made of high-heat stainless steels for refractory applications are also available.

Visitors will learn about the FLEX-MAT and FLEX-MAT Modular active wire screens and how they effectively screen at strong vibrations. This enables them to increase throughput, produce a cleaner product and avoid agglomeration of the fine material.

Haever & Boecker says that the most important prerequisite for the efficient processing of building materials is a thorough material analysis. At Haver Particle Analysis, visitors can learn more about the Haver Inline systems, which allow them to perform shape and size analysis of their building materials in real time directly on the conveyor belt.