The sand and gravel company has been processing fine and coarse aggregates since the mid-1980s, supplying sand and aggregates to the Texas construction industry.

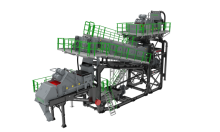

The company experienced first-hand the benefits of CDE’s modular approach when it acquired the current site at Ravenna, Texas. The full sand washing plant was disassembled and containerised at Fort Worth, then relocated and installed by Resolve Aggregates employees in just 11 working days in May of 2017. It was recommissioned by CDE shortly after. The move, combined with CDE’s tailored wet processing solution, enabled Resolve Aggregates to expand their current wet processing system.

The partnership between Resolve Aggregates and CDE has been successful with sales growth from 73,000 tons/month in its first twelve months of operations in Ravenna to an average of 129,000 tons/month thus far for 2021. Resolve Aggregates is therefore building upon its existing sand and gravel washing plant and the relationship with CDE by upgrading their plant for integration of a fine screen to diversify into golf sands to extend its product offering further.

CDE’s modular approach means its equipment can fit seamlessly into the existing process to minimise plant downtime while upgrades are commissioned.

The upgrade includes an Infinity F1-64 fine screen, integrated into the plant and providing an additional cut point within the existing fine sand product, allowing the production of a specialist, high-value golf sand.

The new screen will process 50tph of sand and gravel pit and produce certified, in-spec #30 cut - #140 golf sands. Through CDE’s guaranteed equipment performance, the final materials will meet the high standard requirements from the golf industry and enable Resolve Aggregates to supply valuable products for new markets.

Commenting on the upgrade, Resolve’s spokesperson said: “Our relationship with CDE has been one of collaboration and trust, working with them to ensure the best for our company as we explore both new pastures and new markets. It is remarkable how a simple upgrade has built so easily into our existing plant while opening new possibilities for our company.”

James McShane, CDE business development, North America, said: “This upgrade is a prime example of and great testament to the flexibility of CDE solutions. The extensive benefits of one straightforward addition highlights the ease of plant expansion with our modular approach and how it contributes to the future growth and success of a company that continues to develop and enhance its processes.

“We have been working with Resolve Aggregates for six years and have seen such marked differences in the company. From a relocation to venturing into new avenues that help maximise return on investment. With full accountability for the service and direct support from our team, we look forward to continuing the journey as Resolve Aggregates grow further.”