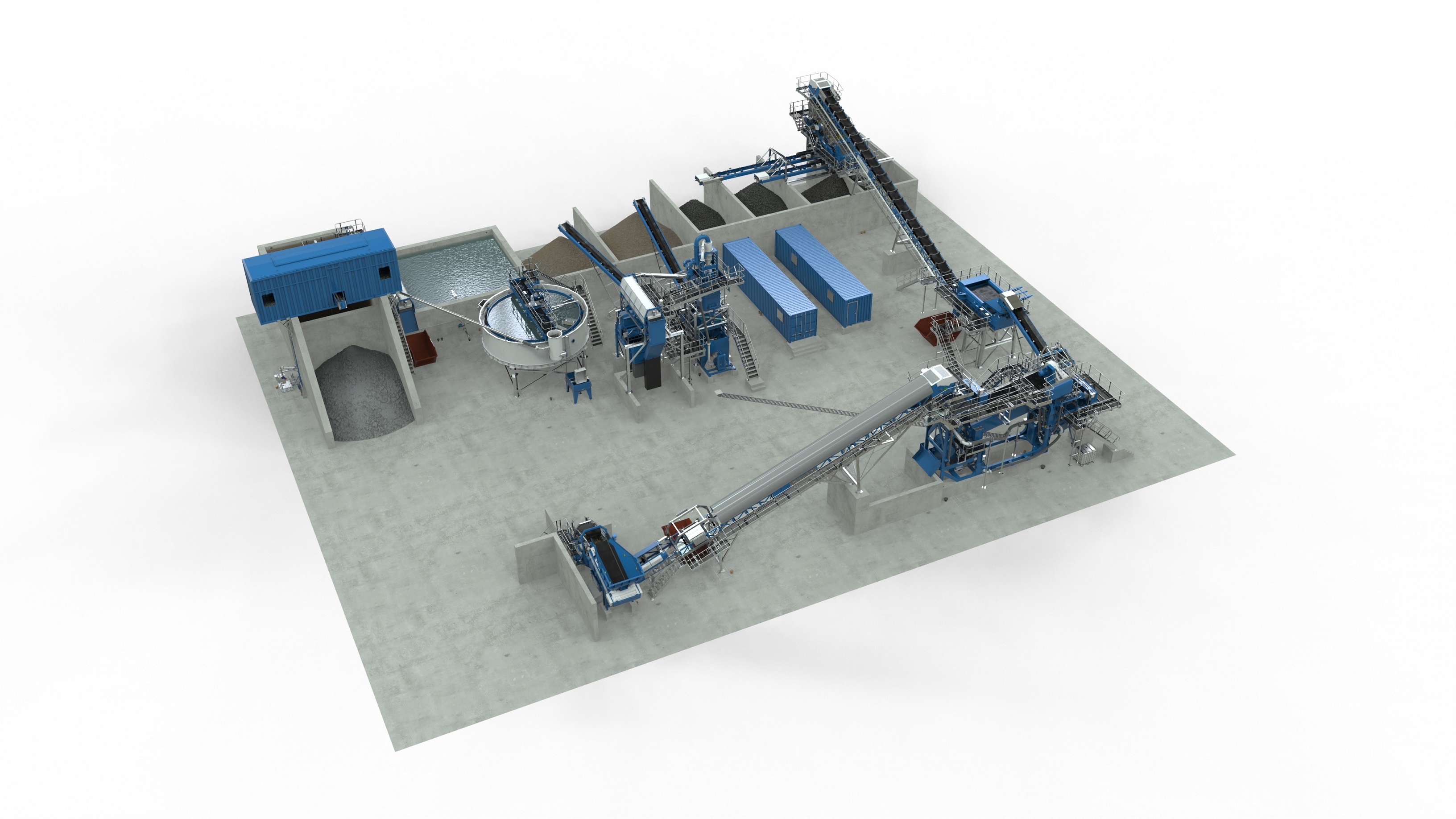

The new 90tph wet processing solution with integrated eddy current separator (ECS) for separating non-ferrous metals from the waste stream is designed and engineered by Northern Ireland-based CDE.

ACe Liftaway says that, when commissioned, it will provide it with the technology to advance the circular economy in Hampshire and its neighbouring counties.

The plant will be located at the company’s Yokesford Hill site, home to an existing waste recycling and grading plant that was installed in 2008, where Ace Liftaway recycles up to 90% of all incoming dry waste streams from its business activities, producing recycled aggregates for the construction industry.

One of the industry’s most difficult materials to process, trommel fines constitute a large proportion of the remaining 10% of waste processed by Ace Liftaway and are typically sent to landfill incurring high charges for the business.

Ace Liftaway MD Philip Liddell says its investment in the CDE solution will help close the loop.

“The core of our business is skip hire services and we’re proud of the very high recycling rates we’ve achieved to date through the dry processing techniques we use at Yokesford," Liddell says. "However, the residual stream from this process, our trommel fines, requires a more robust approach and that’s why we’ve partnered with CDE.

“Trommel fines have a lot of value in them and we want to try to extract that value."

Generally, trommel fines are produced as part of the recycling process and consist of materials such as wood, aggregate, sand, glass, and organics.

CDE’s business development director for the UK and Ireland, David Kinloch, says trommel fines contain more resource than they do waste.

“Trommel fines are a source of significant cost for contractors, but also one of opportunity," Kinloch adds. "Whether they are subject to the standard or lower-rate landfill tax they represent a business expense, that is unless they are processed effectively. With CDE technology, a business can transform that cost into a fresh revenue stream through the recovery of clean sand and aggregates extracted from their trommel fines waste.”

The fibrous nature of trommel fines often makes them difficult to separate and recycle so they have traditionally been sent to landfill, delaying, rather than addressing, the problem. As they are traditionally high in lightweight, organic content, trommel fines fail to meet the specified Loss on Ignition (LOI) threshold of 10%, therefore incurring the standard, and higher, landfill tax rate.

Ace Liftaway is a family-owned and managed business established in 1988 by husband and wife team Philip and Melanie Liddell. Over the past three decades, the business has grown from one truck and eight mini skips to over 1,500 skips of various sizes available for hire throughout Hampshire, Wiltshire and Dorset.