Longcliffe says the new facility will contribute to its ongoing efficiency goals, as well as to its objective of reaching zero-carbon quarrying operations by 2027.

Longcliffe’s Derbyshire quarries have supplied high purity calcium carbonates for nearly 100 years. Longcliffe produces over 100 products for a range of industries including animal feeds, pet foods, glass, plasterboards, plastics, adhesives, pH correction and flue gas desulphurisation. Cure activators produced at Longcliffe have been used in the fluoroelastomer docking seals on the International Space Station.

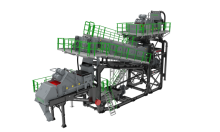

The new washing plant will enable the transformation of material with a higher clay content, at a rate of 220 tonnes per hour, into valuable single-sized aggregates and sand grades. This will allow Longcliffe to recover key products from material that traditionally had to be discarded, maximising the company’s available reserves, and saving 12% of the quarry's load & haul fuel usage.

Viv Russell, managing director of Longcliffe Quarries said: "This new development strengthens Longcliffe’s position as a champion of sustainability in the quarrying sector. Since 2014/15, onsite energy intensity has fallen by nearly 20%, and with the addition of two wind turbines, Brassington Moor quarry’s net emissions have fallen by almost 70%. Extensive tree planting and investment in natural capital – notably in the creation of three nature reserves – complement these carbon reductions, ensuring that Longcliffe remains a leading example of good practice in the industry, and continues to be one of the leading employers in the Derbyshire Dales."

David Kinloch, regional manager for CDE commented: “The plant, a fully optimised turnkey solution, will provide Longcliffe with the capacity to utilise available resources to their fullest potential by extracting maximum value from previously disregarded by-product material due to its high clay content. This will facilitate the company’s growth and further strengthen our shared purpose for a sustainable future.”

Derbyshire Dales MP Sarah Dines, who presided over the official opening of the plant, said: “I am so proud to have such a critical industry so vital to national infrastructure in my constituency and was pleased to be able to open their new plant alongside their hard working team who made it all happen.”