A Volvo Penta engine has been helping to improve aggregates production at a quarry operated by Swedish-based ABBEMA.

ABBEMA was founded 20 years ago by owner and managing director Benth Winqvist as a hobby project, and today provides construction and crushing services in southern Sweden. In total, the company has 25 machines, including eight stone crushers.

The company wants to be at the forefront as a service provider so it needs to stay up to date with the most innovative machines like the Metso LT 330D with a Volvo Penta D16 engine – which is currently in operation at a quarry in Mjölby, Sweden.

The LT 330D is a secondary crusher combined with a three-deck screener that stands behind the primary crusher. It makes the primary crushed material finer and can make three different fractions of material at the same time.

Winqvist says the LT 330D is “the biggest machine you can have without having to dismantle to transport to a new site. The machine is mobile, it moves around in Southern Sweden – 400-500 km.”

It produces aggregates for road building and concrete and has been in operation for two years.

The crusher is larger than others in ABBEMA’s fleet and Winqvist says it was required to increase the operation capacity in response to high demand.

The Volvo Penta engine helps the crusher achieve crushed material outputs of 220 tons crushed an hour at grade 0-16 (small), and 350 tons crushed an hour at grade 0-90 (large).

Setting out the benefits he has observed from using the D16 engine, Winqvist says: “Very reliable and except for the service it’s just running. As the quarry environment that this machine is operating in is very harsh and dusty, we have decided to stick to a 500-hour service interval time rather than the 1,000 hours – we believe it is better to err on the side of caution.”

He adds that scheduled services make everyone feel secure and that ABBEMA has had no unscheduled downtime in the two years it has been running the crusher.

“Since this is our first Volvo Penta engine, we had to establish contact with a new dealer network,” Winqvist says. “As it’s a mobile operation we are dependent on dealers situated at different locations which can be a challenge. Thanks to clear dialogue and good cooperation everything is running smoothly.”

Fredrik Larsson, global OEMs’ key account manager at Volvo Penta, says his company strives to continuously improve and have a service network of suitable density.

“We work proactively with our OEMs to establish good relationships between their dealers and our dealers before the machines are put into operation,” adds Larsson. “Personal relationships are key here. In this case, our dealer in Sweden is working closely with Metso to deliver the best customer satisfaction possible.”

Winqvist says ABBEMA plans to purchase more Metso machines fitted with Volvo Penta engines in the future.

ABBEMA’s strategy is to run its machines for around four years and then replace them with the latest technology. Its machines experience high levels of wear and tear in the quarry and construction environments, so repowering is often not a viable option for their business.

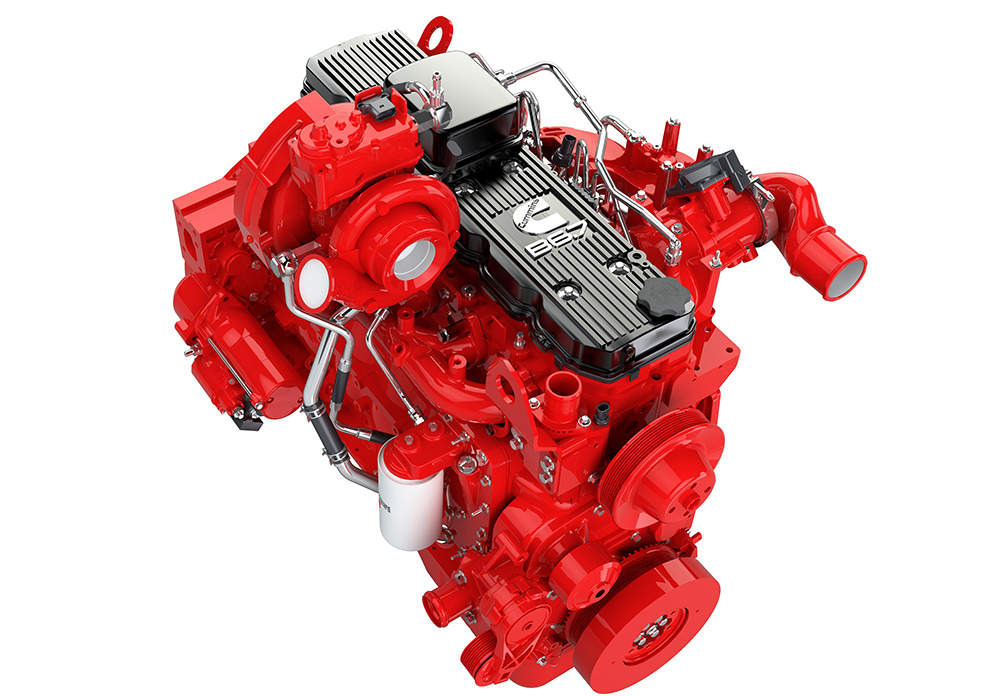

Cummins has announced that its Performance Series engines will be certified to meet Indian Bharat Stage IV and V, as well as China Stage IV emission regulations for the off-highway market. Whilst these products already meet EU Stage V and EPA Tier 4 Final levels, the US-headquartered manufacturer says this development offers excellent flexibility for its customers around the world.

In April 2021, the Bharat Stage IV emissions regulation came into force in India for wheeled machinery, with Stage V planned for the end of 2024. Emissions rules for tracked construction equipment are expected in 2022. The Cummins B6.7 Performance Series engine’s Bharat Stage IV and V certification is now complete, with the L9 and X15 engines due to follow later in 2021.

China Stage IV emissions regulations come into effect at the end of December 2022. Certification of Cummins Performance Series engines F3.8, B6.7, L9, and X15 will be completed during 2022 in advance of the regulated date.

Cummins says that customers that have their own manufacturing capability in India and China will be able to use locally designed and produced engines. OEMs will be able to reduce manufacturing complexity and engineering costs by having common machine designs, regardless of their destination, taking advantage of the key Performance Series benefits.

Cummins adds that Performance Series equipment benefits from the use of the integrated Cummins Single Module aftertreatment system. The system comes with combustion and air-handling technology that supports engines to meet, and exceed, Stage V ultra-low emissions levels, without the need for cooled exhaust gas recirculation (EGR). The single module combines a diesel oxidation catalyst (DOC), a diesel particulate filter (DPF), and selective catalytic reduction (SCR) urea-dosing technology in one unit, offering OEMs a simpler installation to minimise costs.

Having no EGR means that the Performance Series engines are low-weight, simple designs, allowing for easier installation into equipment. Cooling requirements are also lower, further reducing installed costs and occupied space within machinery.

Cummins says that running costs are reduced and extended downtime is avoided across its Performance series, as the range offers significantly improved fuel efficiency, extended service intervals and simpler servicing requirements. Stop-start capabilities can also now be integrated to further reduce fuel consumption, CO2 emissions and overall maintenance costs, helping to reduce on-site exhaust emissions and noise.

Performance Series products can be specifically tailored by Cummins’ engineers mechanically and electronically to each machine type, making equipment installations as bespoke as possible. The manufacturer says this powertrain integration capability delivers the best all-round performance and running costs to match any required operating cycle.

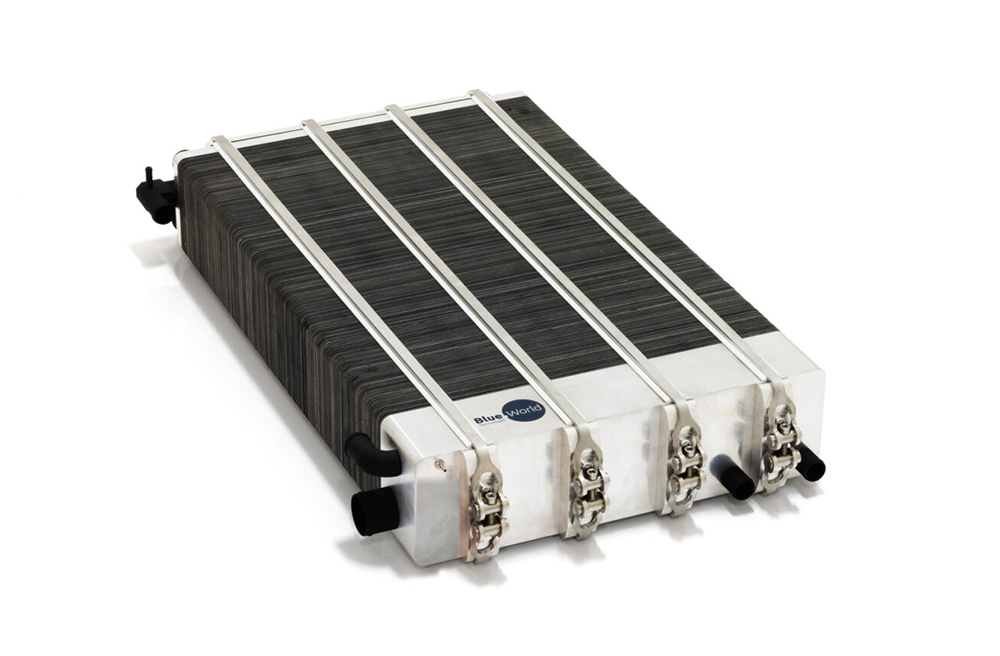

German engine maker Deutz has agreed to enter into a strategic alliance with Blue World Technologies.

Blue World, based in Aalborg, Denmark, develops, manufactures, and sells fuel cell stacks, reformers and systems. The collaboration is centred around an exclusive agreement for the distribution and service of stationary fuel cell gensets and will see Deutz take a 10% stake in Blue World after the due diligence process is finalised. This is expected for Q4 2021.

Blue World employs methanol as an energy source, from which it first generates hydrogen and then, in a second step, generates electrical energy in the fuel cell. Blue World is already developing stationary fuel cell-powered gensets today. In the future, Deutz expects that the fuel cell technology shall be used for mobile applications in the off-highway segment, too.

“By partnering with Blue World Technologies, Deutz is expanding its activities in the development of climate-neutral drive systems,” says Dr. Frank Hiller, CEO of Deutz. The two companies are initially signing a distribution agreement that will allow Deutz to sell the Blue World stationary fuel cell genset exclusively.

Hiller continued: “In the business with gensets, we see an exceptionally attractive market that we are looking to tap into together with Blue World. Genset users are now expecting zero-emission, climate-neutral technology for their applications too. Fuel cells that run on ‘green’ methanol provide an ideal solution here. Deutz is thus making further headway with new technologies that will move it beyond the conventional engine to offer climate-neutral solutions even for the off-highway segment and stationary applications.”

Deutz only very recently presented the TCG 7.8 H2 hydrogen engine, which the company is adding to its portfolio of low-emission and zero-emission drive systems. The engine meets the carbon criteria set by the EU for zero emissions.

“We are very excited about this partnership with Deutz. It means we will be able to work with one of the world’s leading developers and manufacturers of engines on the joint development and distribution of our fuel cell technology. Deutz’s investment is also giving us a boost ahead of our planned public listing. Our partnership with Deutz will be a major contribution towards meeting our mutual goals,” states Anders Korsgaard, co-founder and chief executive officer of Blue World Technologies. “Furthermore, we are happy to announce that Vaekstfonden, the Danish Growth Fund, also expects to take a significant stake in Blue World Technologies. We have a strong relationship with Vaekstfonden, and with these two strategic partners on board, we can speed up the process of building one of the largest fuel cell factories in Europe to meet customer demand.”

Engine maker John Deere has made an equity investment in ClearFlame Engine Technologies, a new firm developing clean-engine technology. ClearFlame’s solution allows low-carbon fuels such as ethanol to be integrated into compression ignition engines, offering a sustainable solution without compromising engine performance.

The company explained that its investment is in line with its strategic vision to accelerate low- and zero-carbon powertrain technology. John Deere will also supply an engine to use in conceptual testing, which will help validate the technology currently under development by ClearFlame.

“We made this investment to stay on the leading edge of developments in renewable fuel technology,” said Pierre Guyot, senior vice president, John Deere Power Systems. “ClearFlame’s compression ignition engine technology has the potential to reduce CO2 emissions while continuing to provide the performance and durability our customers expect from John Deere engines.”

“ClearFlame’s mission is to decarbonise the hardest-to-electrify sectors in a rapid and cost-effective way. Expanding our solution from heavy-duty trucking to agriculture and other off-highway markets delivers on that promise, offering significant sustainability and economic benefits that won’t compromise engine performance,” said BJ Johnson, ClearFlame CEO and co-founder. “We look forward to working together with John Deere and supporting its commitment to reducing net CO2 emissions through providing renewable energy solutions.”

Using ethanol in place of petroleum diesel fuel in diesel engines reduces carbon emissions and air-quality emissions. In addition, ethanol is widely available and can offer a high-efficiency, liquid alternative fuel option.

The firm recognises the importance of renewable fuel options and is committed to exploring new solutions. “Compression ignition engines have a long life ahead — in terms of both the current source of diesel and a wide variety of alternative fuel types,” said Guyot. “John Deere already offers biomass-based diesel compatibility on our engines. These investments are the right thing to do for environmental, economic and rural-development benefits.”

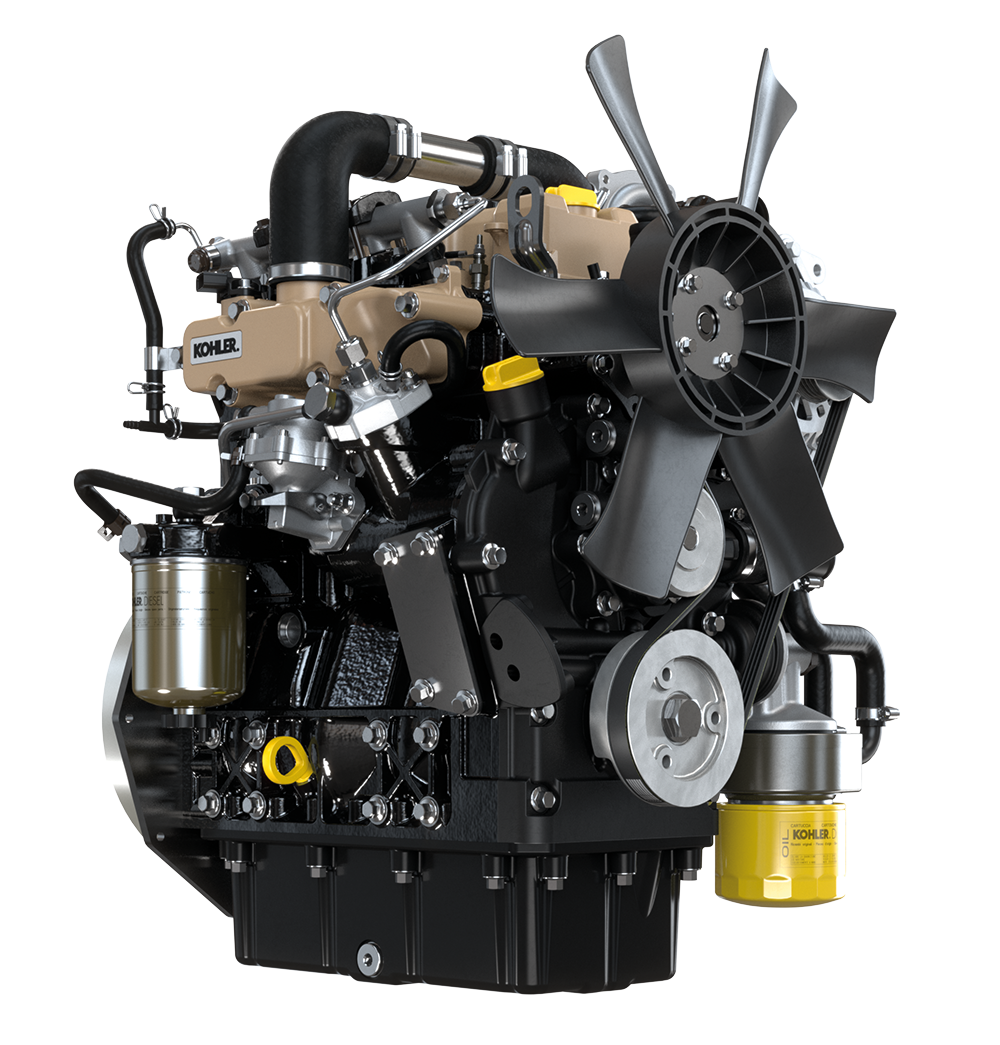

Kohler unveils KSD Series engines

Choosing the right engine for any equipment – from generator sets (gensets) to specialised machines – requires time and significant investment.

With this in mind, off-road engine maker Kohler says its new KSD Series (Kohler Small Displacement) engine family is designed to be advanced but simple and suitable for a variety of applications. The KSD is a new base engine below 19kW that complies with all global emissions standards and fuels. Announced in November

2021, the new engine range is scheduled to go into production in October 2022.

Kohler says KSD engines are ready-to-fit machines for excavators and loaders in construction, generators in the power sector, tractors in agriculture, and forklifts in logistics, as well as compressors, dumpers, mowers, and refrigeration.

The new range currently comprises three engine models: KSD 1403NA (naturally aspirated), KSD 1403TC (turbocharged), and KSD 1403TCA (turbocharged with aftercooler). The Wisconsin, US-headquartered manufacturer says many others will come in the next few years.

In terms of performance, the KSD series offers high low-end torque (95 Nm @ 1000 rpm); peak torque at low speed (120 Nm @ 1400 rpm), and peak power (18.4W @ 1800 rpm).

Kohler says the “amazing” low-end torque values allow the operator to run their piece of equipment at lower rpm to save fuel.

Kohler says the “amazing” low-end torque values allow the operator to run their piece of equipment at lower rpm to save fuel.

It adds that the wide variety of emission standards has introduced a new level of complexity to the engines business. “We have taken this complexity and transformed it into an opportunity,” the company states. “It happened with the KDI Series, and it’s happening with the product we are presenting today: a new engine below 19kW that complies with all global emissions standards and fuels. And multi-fuel solutions will enrich the offering: diesel, gasoline and propane.”

Kohler says that a truly global product must be conceived and designed with a global approach: suitable for all regions, compliant with all standards worldwide, and compatible with all kinds of machines.

“Integrating an engine in any piece of equipment doesn’t mean just selecting and purchasing it,” the company comments. “Our passionate global team offers support throughout the process, during and after the engine installation, wherever you are, whatever machine type you have.”

In terms of simplicity, Kohler says KSD engines can be easily integrated with the more complex electronic systems of ever-evolving machines. It adds the engines are also versatile and can be integrated without modifying or redeveloping the machine. KSD engines also allow customised settings for any duty cycle and the ability to exchange data with few physical connections.

The KSD engines have the ability to easily fit into existing machine platforms. They are electronically managed, while also being designed to be as simple to use as mechanical engines. The fuel system allows precise fuel metering and excellent load response, resulting in time saving and increased productivity.

Kohler says the innovative technology brought on by the KSD series is its architecture which features a state-of-the-art indirect injection system but has the electronic management typical of direct injection engines.

For servicing, the KSD engines allow for prognostic, diagnostic, geolocation, remote monitoring and “switchability” for generator set application. They offer a service interval of up to 500 hours, for both oil and fuel filters. The 2,000-hours of service interval of the Poly-V fan belt and no valve adjustment give KSD engines a 3-year warranty providing up to 6,000 hours of protection.