Dynamic Weigh Systems (DWS) has been appointed the sole agent for the VEI Group line of on-board weighing and payload management systems in southern Africa.

According to Ivan van Heerden, managing director of DWS, VEI’s non-load-cell weighing technologies offer accuracies of between 99 and 100% on properly calibrated machinery. In fact, the technology has been licensed as “legal for trade” in Europe and has been granted National Regulator for Compulsory Specifications (NRCS) approval in South Africa for several applications.

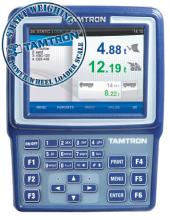

The various models can be fitted on any machine with a lifting piston – from wheeled loaders and small forklifts to the largest rigid dumper trucks and excavators. Installation is non-invasive and requires no cutting or welding on the chassis. All telemetry is routed to the in-cab units and there are no external junction boxes.

The systems are robust, with IP65 ratings on the display units and IP68 ratings on the sensors. “The units have been designed with the ‘third world’ in mind with simple, intuitive controls for the operators. Training usually takes less than an hour with the drivers reaching maximum efficiency within the first several hours of operating the machinery,” says Van Heerden.

The accuracy of the units and their ease of use mean that loading efficiency is significantly increased, especially where axle weight loading is important. They can be coupled with VEI’s range of high-speed thermal printers, memory sticks and either RF, Wi-Fi or cellular modems. The latter allows for real-time tracking of production, often important in remote locations where an office may not be present.

VEI also provides multi-user payload management software which quickly puts information at managers’ fingertips. DWS can streamline and improve loading efficiency, leading to rapid return on investment and increased profitability.

As far as case studies go, DWS has already worked with South African based Afrimat, a leading provider of industrial minerals and construction materials, at its Marble Hall quarrying operation. Here, Van Heerden says the company has improved the quarry’s truck throughput by almost 90% and reduced the returns from the weighbridge to the stockpile drastically.

“At Blurock Quarries in Estcourt, KwaZulu-Natal, South Africa, our systems helped detect a problem with the weighbridge on site. There was a 300 kg discrepancy from one end of the deck to the other. We found the problem because we calibrated the loader on the one end and most of the trucks were weighed near the other end and the weights didn’t match. The weighbridge supplier had to re-calibrate the deck and saved the quarry from charging for less than what was being loaded,” concludes Van Heerden.