In line with international trends, LoadTech Load Cells, a leading supplier of on-board weighing systems, reports increased uptake of its LOADRITE on-board weighing technology in the African market, writes Munesu Shoko.

Regardless of application, the challenge for site and fleet managers is the same: achieving maximum value from existing equipment by utilising it in the most efficient manner. The key to making effective decisions is having the right information available and on-board weighing systems have become the gold standard internationally.

On-board weighing systems are among the very best technologies used to determine payload weights today. These technologies make it easy for site managers to assess and record those very important metrics which may raise the operation’s profits. Keeping this in mind, several African aggregates and mining customers are following the global trend of adopting these technologies to optimise their loadout processes.

Christiaan Luttig,

“Aggregates and mining have benefited the most from the LOADRITE weighing systems, and conclusive return on investments has proved this fact through studies done on sites prior to installation and measuring changes after installation,” says Luttig.

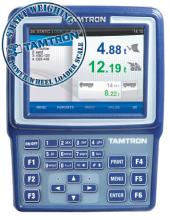

LOADRITE, a Trimble company, is a renowned supplier of on-board weighing systems designed for wheeled loaders, excavators and conveyor belts, from entry-level through to advanced functionality options. Within the three product types, the company provides two product offerings in each category to suit different customers’ requirements.

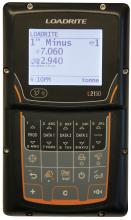

The LOADRITE wheeled loader scales comprise the L2180 and L2150. The LOADRITE L2180 can be easily configured to suit a wide range of industries, including sand, stone and gravel, public works, as well as waste and recycling. It is said to be the most popular scale in the LOADRITE product range, accounting for 70% of all installations globally.

The L2150 is a user-friendly weighing system designed for ease of use with fast access to menus and data. By using multiple-point triggering, speed compensation and dual pressure measurement, the L2150 is said to offer high-level weighing accuracy regardless of lift speed and loader movement. The screen display is uncluttered and only relays pertinent information to the operator when required. This enables the operator to concentrate on the loading process without unnecessary distractions.

The Active Tip Off feature allows the loader operator to adjust the last bucket load to any height. This is possible due to the rotary position sensor which allows the scales to compensate for boom position. “LOADRITE uses a rotary position sensor to continuously monitor boom position over the entire lift, allowing multiple measurement points. Multi-point weighing allows variations in weights calculated to be averaged out or even discarded if outside tolerance levels. The variances can be caused by inexperienced operators or weighing on rough ground,” says Luttig.

Meanwhile, the LOADRITE X2350 excavator scale uses proprietary technology to achieve accurate weighing to +/-3% margin of error with no disruption to the operation of the excavator. The dynamic payload weighing system is said to ensure bucket-by-bucket optimisation of the load-out processes. The bucket sensor is installed on the bucket or quick-hitch. It measures the angle of the bucket to provide increased weighing performance and a larger operating area for the operator.

The LOADRITE trigger units are mounted on the boom and stick pivot point. They sense the position of the excavator boom and stick arm to ensure measurement accuracy. The X2350 indicator is mounted in the cab, and it receives data from the sensors and calculates weight. Meanwhile, the LOADRITE angle sensors, mounted on the excavator chassis frame, provide machine angle and movement information used to compensate for variable ground slope conditions and provide greater accuracy of measured weights.

Speaking of key benefits of LOADRITE’s loader and excavator scale solutions, Luttig explains that hydraulic weighing is affected by temperature, but LOADRITE wheeled loaders and excavator weighing systems with friction and ambient compression technology (FACT) compensate for hydraulic temperature, bearing, machine friction and lubrication levels without the additional expense of extra sensors.

He also adds that when weighing on uneven ground, centre of gravity greatly affects the weighing accuracy. LOADRITE’s exclusive ground slope compensation allows for accurate weighing on any surface angle or ramp.

Elsewhere, LOADRITE belt scales are said to give plant operators and managers a range of powerful tools to measure the actual production from screens and crushers, track final product stockpiles, analyse plant and machine downtime, as well as monitoring loadout of trucks.

The LOADRITE C2850 is best suited to mobile conveyor belt applications, while the C2880 for fixed plant brings multiple conveyors onto one display. Explaining how these scales work, Luttig says the integrator is the processing engine that converts signals from the load cells and speed wheel into weighing data. The speed sensor provides data to calculate belt speed, flow rate and total weight, while the scale assembly measures vertical forces for an accurate weight signal to the integrator.

“Communications can send conveyor information to a remote display, a PLC (programmable logic controller), local computer or web-based reporting via Ethernet, or wireless communication (optional),” says Luttig. Remote display is designed so the office or control room can monitor and control all LOADRITE belt scale integrators. It also allows data entry of downtime reasons (optional). LOADRITE belt scales can measure the fuel or energy consumption of a motor or electric engine via a fuel gauge or energy meter connected to the motor (optional).

Having a weighing system installed is one thing, but being able to keep track of production is quite another. Luttig argues that fixed and mobile equipment is a major investment, and Trimble’s InsightHQ, a web-based software, helps optimise assets by tracking productivity.

“Efficient use of fixed and mobile equipment is key to maximising profits. InsightHQ (web-based) and Materials Management System (for PC) reporting platforms are specifically designed for loading and quarrying operations. LOADRITE can track the stockpile inventory levels and loader tasks, for example, stockpiling vs. loadout, when using data fields,” says Luttig. “LOADRITE reports on key metrics of the quarry operation – pit processing and loadout – empowering quarry managers to optimise their production, not just a scale on a loader.”

InsightHQ is a quarry management portal that shows near real-time productivity, availability and performance dashboards and reports for extraction, processing and loadout. To view changes over time, the site manager can adjust reports to suit either the shift, day, week, month or year.

Snapshot connects with LOADRITE scales to present near real-time data so the site manager can react during the shift. In terms of equipment management, the InsightHQ loading performance summary helps staff understand product throughput by weight and by truckloads, while simple and accurate visibility of conveyor TPH and performance helps production teams meet daily targets.

“InsightHQ presents information in simple, easy-to-consume chunks, or drill down into raw data to identify specific issues or bottlenecks,” says Luttig, adding that InsightHQ is a fraction of the cost of similar PLC or SCADA-based reporting systems, but offers additional functionality.