The carbon neutral lubricants are now available in key markets across Europe, Asia-Pacific, the Middle East and North America. Shell says it will offset the emissions from a mix of advanced synthetic lubricants in these markets, including Rimula and Rotella for heavy duty diesel engines, and a wide range of premium industry lubricants, including Shell Omala in the wind sector, Shell’s range of eco-Label products “Shell Naturelle”, and the Shell Gadus greases product range.

The company says it aims to offset the annual emissions of more than 200 million litres of advanced synthetic lubricants, expecting to compensate around 700,000 tonnes of carbon dioxide equivalent (CO2e) emissions per year, which is equivalent to taking approximately 340,000 cars off the road for one year.

“Shell has set a target to become a net-zero emissions energy business by 2050, in step with society and our customers,” said Carlos Maurer, executive vice president, global commercial at Shell. “We know our customers are looking for ways to reduce their net carbon footprint, and as the world’s leading lubricants supplier we have an important role to play. That is why I am pleased to announce the largest carbon neutral programme in the lubricants industry, and one that compensates for the full lifecycle emissions of our products."

Shell Lubricants says the carbon neutral lubricants launch represents a key milestone in its multi-year strategy to help customers manage their sustainability needs and its ambition to reduce the carbon intensity of its products by avoiding, reducing, and offsetting emissions. Since 2016, Shell claims to have reduced the carbon intensity of its lubricants manufacturing by over 30%, and over 50% of electricity used in its lubricant blending plants now comes from renewable sources. Shell is also reducing packaging waste from lubricants products at scale by increasing the use of recycled materials and exploring more sustainable packaging solutions across its supply chains.

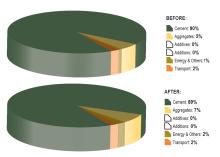

The company adds that, while measures to avoid and reduce emissions offer the best way to tackle emissions in the long term, until scalable solutions are deployed, carbon offsetting programmes provide an immediate solution to balance CO2e emissions across Shell’s portfolio and value chain. Shell’s global portfolio of nature-based carbon credits will compensate CO2e emissions from the entire lifecycle of these products, including the raw materials, packaging, production, distribution, customer use and product end of life.