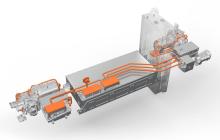

By using hydrogen as a renewable fuel source, the new dual-fuel engine – which is an evolution of the company’s proven D8 model – is claimed to cut CO2 emissions by up to 80%, without impacting power or performance.

The engine operates in a similar way as the conventional D8 model, but uses mainly hydrogen instead of diesel. If hydrogen is not available, the engine can continue to run on traditional fuel, safeguarding productivity and uptime. This means that with dual fuel technology, assets and business operations can be future-proofed – despite the fact we don’t have full coverage from a reliable hydrogen infrastructure in place today.

“The new Volvo Penta dual-fuel hydrogen engine offers customers a low-carbon interim solution before suitable zero-emissions alternatives become viable,” says Anders Wernersson, product manager for the dual-fuel hydrogen engine. “It delivers the same power and torque curve as a regular diesel engine but with significantly lower CO2 emissions. The technology is relatively simple and can be installed with minimal disruption, so we see this as being a cost-effective and robust solution for customers in a variety of applications – including construction and mining – who are looking to transition to net-zero emissions.”

Volvo Penta has partnered with CMB.TECH to develop the dual-fuel hydrogen-powered solution. CMB.TECH provides and trials the hydrogen add-on kit and tank system that works together with the Volvo Penta D8 engine and software. Currently, the engines are being run in test cells to optimize the hydrogen-diesel injection strategy for maximum reliability and emissions savings.

The first engines will be working in end-customers machines in Europe in 2023 as part of a market pilot project, which will be followed by small-scale production. It will be a stepwise introduction based on market and customer demand and there will be a focus on the fit between the technology and customer needs, ensuring it makes sense to choose a dual-fuel powertrain.

“Collaboration and partnerships are essential to facilitate the transformation towards more sustainable power solutions,” says Wernersson. “This close partnership approach is a cornerstone of Volvo Penta’s long-term decarbonization and business strategy. We work closely with our customers and partners to create tailored solutions based on their requirements.

Volvo Penta also highlighted at bauma how it is expanding its services offering, with a sharp focus on creating value with customers through connected solutions.

The company used the Munich event (which took place from October 24-30) to talk to customers about how it can improve uptime for OEMs and end-customers through connected power solutions. The company has run several connectivity pilots together with customers in different industrial segments. These have focused on the technology and new, proactive ways of working to deliver value-adding services to meet customers’ needs. Volvo Penta has connected units, including electric drivelines, operating in selected industrial sub-segments and the company is continuing to establish strong collaborative partnerships with customers.

“We have a co-operation and co-creation stepwise approach to connected services which involves having the whole value-chain – from the end-user to the service network – in mind,” says Victor Hugo Castillo Gutiérrez, director uptime & productivity services at Volvo Penta. “We work closely with our OEM customers to fully understand their needs, application and environment, in order to identify the value-added services. This, together with analyzing the engine data to maximize uptime, is the backbone of our connectivity offer.”

The engine or power solution is a critical machine component that has a major influence on uptime. Volvo Penta’s strength and expertise lie in this area, together with the related software, so the company can use this knowledge to help customers improve productivity and uptime through connected engine solutions.

Connectivity enables the real-time monitoring and measuring of a power solution’s status. By having a connected diesel engine or electric driveline, any emerging or potential issues can be detected through the data and dealt with quickly and efficiently before bigger problems occur – helping to maintain and increase uptime and productivity. By knowing what the problem is, you get more efficient diagnostics as dealers can approach customers with the issue and arrive with the right tools, parts and expertise to fix the problem.

“We see the connected services we provide as being an integrated component of the services that OEMs provide to their end-customers,” says Gutiérrez. “Our engine is a critical component and our uptime services should be thought of in the same way.”

Volvo Penta started its connectivity journey in its Marine segment several years ago, launching its Easy Connect solution for Marine Leisure customers in 2018. Volvo Penta says its Industrial segment benefits from this shared technology along with the rest of the Volvo Group’s knowledge and experience from having over one million connected customer assets.

“There are endless opportunities ahead to co-create new services offerings to increase uptime thanks to the data from connected engines,” says Gutiérrez. “We can create new, predictive ways of working using data insights to drive efficiency in the whole value chain, increasing the end-customer’s uptime and productivity.”

Volvo Penta initially started working with European OEMs on connected solutions and is now opening up pilots in the US, before expanding the service to other markets.