The manufacturer will use the bauma quarrying, construction and mining equipment event in Munich this October to showcase its plans to provide future sustainable power solutions to meet the industry’s net-zero ambitions.

The company’s display in Hall A4, Booth 526, will provide an overview of how its current portfolio of D5 to D16 diesel engines – and Stage V models in particular – has resulted in technological advances and market share gains that support its transformation journey.

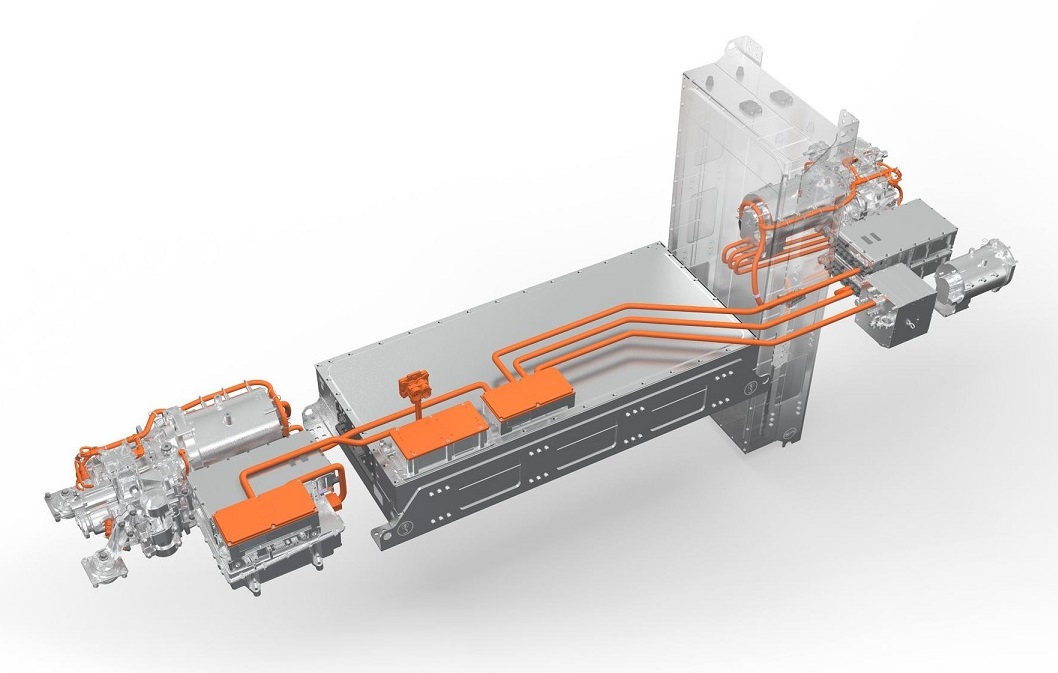

The latest major innovation supporting Volvo Penta’s Science Based Targets initiative (SBTi) to reach net-zero value chain emissions by 2040 will be featured on its booth. The electric driveline, which recently entered production in Rosenbauer’s RT and RTX fire trucks, was originally unveiled in 2019 as a proof of concept in a modified terminal tractor, highlighting the versatility and configurability of Volvo Penta’s electric solutions.

“We take a system supplier approach which means that we can create a flexible, bespoke electric driveline solution for a specific vehicle and application,” says Morgan Blomgren, director strategy & business development. “We are very experienced in a variety of different segments, so by using that knowledge and combining it with the Volvo Group’s proven electromobility experience, we can build the best modular platform for our customer’s applications. With that as a base, we can optimize the design and adapt the complete electric driveline system for a specific vehicle, considering the exact application, usage, climate and environment it will operate in.”

Working alongside terminal tractor manufacturer TICO, for example, Volvo Penta says its experience accumulated during earlier projects enabled it to speed up the development and installation of the complete modular driveline solution and its integration into a fully electric terminal tractor prototype. With TICO simultaneously working on improving the vehicle’s functionality, the first of several units was ready to undergo testing with TICO’s leading fleet partners within just nine months.

“To succeed on our transformation journey, strong collaboration with customers and partners is crucial,” says Morgan. “We cannot deliver the changes that need to happen alone – that’s why we are working so closely with our customers, supply chain partners, governments, societies and other stakeholders.”

Volvo Penta says its Stage V-compliant diesel engines and gensets are a popular choice in a wide range of machinery from crushers and screeners to underground mining trucks. It adds that these engines have been fully optimised to meet customer needs in terms of productivity, uptime and TCO. Passive regeneration of the aftertreatment system has been maximised, for example, eliminating unplanned stops during operation, while fuel consumption has been reduced by up to 5% over the Stage IV models.

The new D16 received the 2021 Engine of the Year award. Volvo Penta says this was largely in recognition of its increased output (796 hp / 585 kW) which was achieved at the same time as an up to 10% reduction in fuel consumption. By incorporating water-cooled charged air, its dual-stage turbo delivers high performance right across the operational range, enabling maximum torque to be produced at both low and high engine speeds.

“In the short-term, the focus is still very much on internal combustion engines and we will continue our development work in this area to stay competitive,” says Morgan. “Our engines are already able to run on HVO and biodiesel, and to further support our transformation journey to zero-emission solutions, we are also looking into powering them with CNG, biogas and hydrogen, as well as the use of hybridization – all of which are likely transitioning solutions for those markets that cannot yet support fully electric solutions.”