Volvo Penta had much to get revved up about at the recent bauma 2019 exhibition in Munich, Germany. Aggregates Business editor Guy Woodford caught up with Björn Ingemanson, Volvo Penta president, and Andreas Viktorsson, Volvo Penta chief project manager, at the big global construction and quarrying machine show to get the inside track on what lies behind the ambitious Volvo Group company’s rapid growth in its off-highway engine sales.

Volvo Penta has increased its annual off-highway equipment engine sales by a highly impressive average of 45% in the last three years. There is a significant factor behind this, as Björn Ingemanson, Volvo Penta president & CEO, explains, “The majority of our annual sales were traditionally on the marine side of the business - around 70% marine to 30% industrial (including off-highway equipment). Then, around eight years ago, we took a decision to really invest a lot in our planning for Stage IV Final emissions-compliant engines and focus on the industrial side of our business. We acquired more than 100 new OEM [original equipment manufacturer] relationships. In a short time just before Stage IV was going to be launched [in 2014], we gathered them all and showed them a lot of our engine prototypes. Soon after, our off-highway equipment orders exploded into life. We’ve kept all but one or two of these OEMs with us and acquired new ones with the launch of our Stage V emissions-compliant engines range.”

Volvo Penta’s Stage V emissions-compliant engines are said to have proven extremely promising in field tests, boasting fuel consumption reductions of up to 5%, compared to their Stage IV predecessors. This not only reduces CO² output but also the total cost of ownership.

With a power range from 105 to 585kW, Volvo Penta Stage V engines (D5, D8, D11, D13 and D16) are said to be specifically engineered to give customers optimum productivity, uptime and total cost of ownership, and are developed to offer ease of installation, operation and maintenance.

The Volvo Penta Stage V range provides improved productivity through an engine and exhaust aftertreatment system that has been designed to work seamlessly. Among other claimed benefits, this maximises passive regeneration during normal operation and, therefore, removes the need for stand-still regeneration. Uptime has also been boosted by improved oil change service intervals, which have been doubled from 500 to 1,000 hours. In addition, Volvo Penta has championed ease-of-installation by ensuring commonality between different emission levels.

Ingemanson said, “I think customers see us as a premium brand offering high quality and a reliable engine. With regards to Stage IV Final, customers liked our compact solution which uses SCR [selective catalytic reduction] technology without the need for a DPF [diesel particulate filter].

“It was good that we didn’t just look for add-ons with our Stage V solution, and really developed the aftertreatment system in sync with the engine. It meant we got something that really gave us something good in terms of lower fuel consumption. Our Stage V offer also stands up very well, from early analyses, against competition.”

“I think customers like the fact that we are a smaller company within a bigger group. They like the benefits of group experience and, from the other end, our agility,” said Andreas Viktorsson, Volvo Penta’s chief project manager.

“We started our Stage V engines project four-and-a-half years ago, but the journey to develop the off-highway engine side of our business, as Bjorn said, started much earlier than that, with the development of engines without DPF.

“Customer focus has also been key in enabling us to cope with growing demand for our off-highway engines.”

Ingemanson believes that Volvo Penta has a firm base from which to pursue further growth for its off-highway engine business.

“There will be continued tougher emissions legislation and alternative cleaner fuel development. There is also the ongoing focus on the electrification of construction and quarrying equipment, which is a topic being discussed more and more by our customer OEMs.”

In addition to its new Stage V off-road engine solutions, Volvo Penta has also recently unveiled its first Stage V engine for mobile gensets: the D16. The D16 is a neat and compact engine with lower maintenance requirements. It is said to deliver around 3% better fuel economy (versus Stage IIIA), providing improved total cost of ownership.

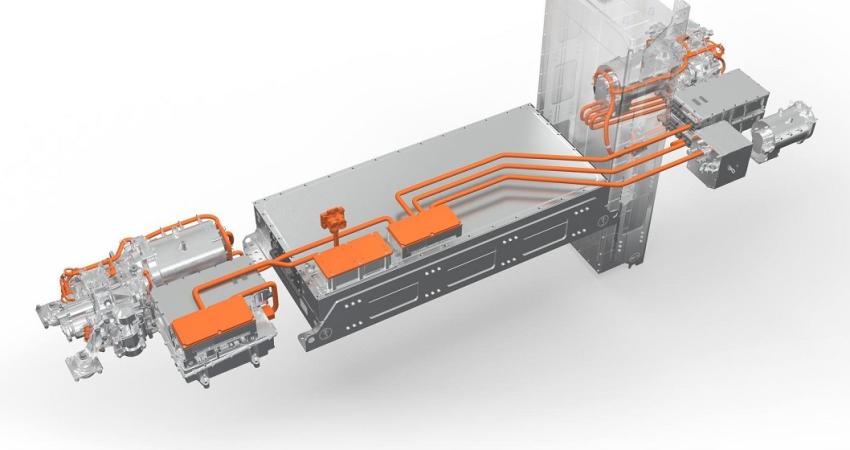

Running parallel with the evolution of its diesel-powered engine solutions is Volvo Penta’s leveraging of the strength of the Volvo Group to bring innovative technology to land and sea. The company has embarked on its first industrial OEM electromobility partnership by signing an agreement to design and deliver an electric driveline for Rosenbauer, a world-class fire-service vehicle manufacturer to which Volvo Penta already supplies Stage IV/Tier 4 Final and Euro VI diesel engines. In a system delivery approach, Volvo Penta will develop the electric driveline in Rosenbauer’s first electric truck due for launch in 2021.

This strategic partnership follows Volvo Penta’s recent announcement that it is providing the propulsion system for Gothenburg’s first all-electric ferry and is a significant step in the company’s plans to offer electrified power solutions to both the industrial and marine segments by 2021.

“We look what is done around engines for the trucks side and the bus side of the Volvo Group business and see what would fit our industrial and marine OEM customers,” said Ingemanson. “The implementation will happen step-wise on the basis that the business case for switching to electric will differ across our many customer segments and applications.

“We are looking at a couple more projects on the off-road engines side of Volvo Penta, but it’s hard to say when they will reach the stage of being commercially viable.”

Ingemanson admits that top global off-highway engine market manufacturers are likely to have to invest more funds into their research and development to achieve all goals within their growing project portfolios. “I think all players will have to invest more to meet all their competing project commitments. It’s a big challenge for everyone.

“R&D [research and development] is the biggest department of Volvo Penta today. We have doubled our R&D investments in five years. We need to continue to grow and it’s very pleasing, looking back, that our strategy to focus on the industrial off-highway side of our business is working out so well.”